Unlocking Efficiency: The Ultimate Guide to Finding Your Perfect Container Delivery Trucks For Sale

Unlocking Efficiency: The Ultimate Guide to Finding Your Perfect Container Delivery Trucks For Sale Lmctruck.Guidemechanic.com

In the demanding world of logistics, waste management, construction, and specialized hauling, the ability to efficiently move and manage containers is paramount. Businesses thrive on speed, reliability, and cost-effectiveness. This is where container delivery trucks for sale step in, acting as the backbone of countless operations. They are not just vehicles; they are critical assets that can significantly impact your bottom line and operational capabilities.

As an expert in commercial vehicle acquisition and fleet management, I understand the complexities involved in selecting the right truck. This comprehensive guide is designed to cut through the noise, providing you with an in-depth understanding of everything you need to know about these essential machines. We’ll explore the different types, crucial buying considerations, and best practices to ensure you make an informed decision that drives your business forward.

Unlocking Efficiency: The Ultimate Guide to Finding Your Perfect Container Delivery Trucks For Sale

Understanding the Powerhouse: What Exactly Are Container Delivery Trucks?

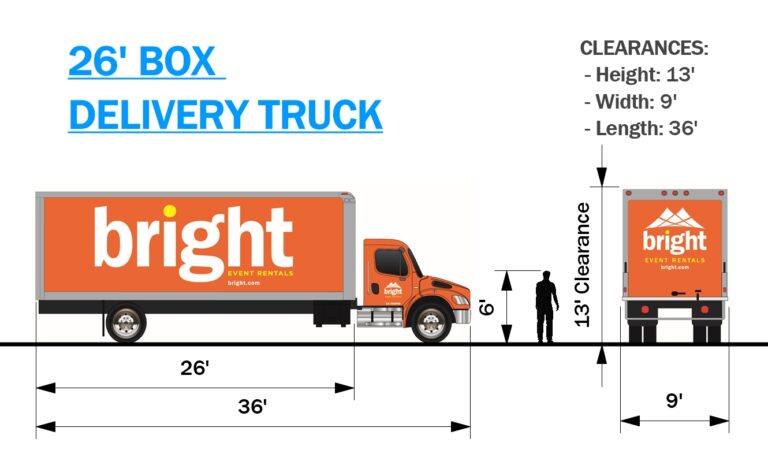

At their core, container delivery trucks are specialized commercial vehicles designed to transport and often load/unload various types of containers. These can range from standard roll-off dumpsters used in construction and waste management to specialized storage containers, recycling bins, and even portable offices. Their primary function is to provide a versatile and robust solution for material handling and transportation.

These trucks are engineered for heavy-duty performance, featuring powerful hydraulic systems that enable them to articulate, lift, and place heavy loads with precision. The robust chassis and drivetrain are built to withstand the rigors of challenging environments and continuous operation. Choosing the right one means optimizing your workflow and reducing manual labor.

Decoding the Types: Which Container Truck Fits Your Needs?

The world of container delivery trucks is diverse, with each type designed for specific applications and operational efficiencies. Understanding these distinctions is crucial for identifying the best fit for your business. Let’s delve into the most common and effective variants you’ll encounter when looking for container delivery trucks for sale.

1. The Indispensable Roll-Off Truck

The roll-off truck is perhaps the most recognizable type of container delivery vehicle, famed for its ability to "roll" a container off its back onto the ground. This mechanism utilizes a powerful hydraulic hoist system, cables, and a tilt frame to slide the container on or off the truck bed. It’s a workhorse in numerous industries.

Mechanism and Operation: The truck backs up to the container, and the hoist system extends a cable to hook the container’s front bar. The bed then tilts, and the winch pulls the container onto the truck or slowly releases it off. This simple yet effective design allows for quick container swaps.

Common Uses: Based on my experience, roll-off trucks are indispensable in waste management for municipal and commercial refuse, construction and demolition for debris removal, and recycling operations. They are also widely used for hauling large volumes of scrap metal and delivering large storage units. Their versatility makes them a popular choice.

Advantages:

- High Payload Capacity: Capable of handling very large and heavy containers.

- Durability: Built for heavy-duty, continuous use in harsh environments.

- Simplicity of Operation: Operators can quickly learn the loading and unloading process.

- Wide Availability: Many manufacturers and models are available, making parts and service accessible.

Disadvantages:

- Space Requirements: Needs ample space behind the truck to deploy and retrieve containers.

- Limited Articulation: Less flexible than hooklift systems for precise placement in tight spots.

- Ground Clearance: Can sometimes struggle on very uneven terrain if not properly spec’d.

2. The Agile Hooklift Truck

Hooklift trucks, sometimes called hook loaders, represent a more modern and versatile approach to container handling. Instead of cables, they employ a large hydraulically operated hook arm that latches onto a container’s front lifting point. This system offers greater flexibility and precision.

Mechanism and Operation: The hook arm can extend, articulate, and retract, allowing the operator to lift, pull, and place containers from various angles. This means containers can be loaded and unloaded without the need for perfect alignment or significant space behind the truck, unlike roll-offs. It’s a game-changer for multi-tasking fleets.

Common Uses: Hooklifts excel in diverse applications, including specialized waste and recycling, transporting multiple types of interchangeable bodies (e.g., flatbeds, dump bodies, salt spreaders, chipper bodies), and military logistics. They are perfect for operations requiring frequent changes of container types.

Advantages:

- Enhanced Versatility: Can handle a wider variety of container types and sizes, often switching between different body styles (e.g., dump body, flatbed, chipper body) in minutes.

- Precision Placement: Offers superior control for placing containers in confined spaces or specific orientations.

- Faster Exchange Times: Often quicker to load and unload containers compared to cable systems.

- Reduced Wear and Tear: Less strain on the chassis due to smoother loading operations.

Disadvantages:

- Higher Initial Cost: Generally more expensive than roll-off systems due to their advanced hydraulics.

- Maintenance Complexity: The more complex hydraulic system can sometimes require specialized maintenance.

- Operator Training: May require slightly more training for new operators to master the precise controls.

3. The Compact Skip Loader Truck

Skip loader trucks, also known as tilt frame or tilt and slide trucks in some regions, are designed for smaller containers, often referred to as "skips." They are particularly adept at maneuvering in urban environments and tight spaces where larger roll-offs or hooklifts might struggle.

Mechanism and Operation: These trucks use a hydraulic system to tilt the entire truck bed backward and slide the skip container off. They typically feature two hydraulic arms that lift and dump the skips, offering a compact and efficient solution for localized waste collection or material delivery.

Common Uses: Skip loaders are a staple for residential waste collection, small commercial businesses, garden waste removal, and light construction debris. They are ideal for routes with narrow streets and limited access points. Many local municipalities rely heavily on them.

Advantages:

- Agility: Excellent maneuverability in urban settings and confined areas.

- Efficiency for Smaller Loads: Perfectly suited for handling smaller skips and bins.

- Lower Operational Costs: Often more fuel-efficient and less demanding on tires due to lighter loads.

Disadvantages:

- Limited Capacity: Cannot handle the large, heavy containers that roll-offs or hooklifts can.

- Specialized Containers: Requires specific skip-style containers, limiting versatility with other container types.

- Less Common: Fewer manufacturers and models compared to roll-offs, potentially impacting parts availability.

Key Factors to Consider When Buying Container Delivery Trucks For Sale

Purchasing a container delivery truck is a significant investment. Making the right choice requires careful consideration of several critical factors that impact performance, longevity, and ultimately, your return on investment.

1. New vs. Used: The Perennial Debate

This is often the first major decision point. Both options have distinct advantages and disadvantages.

- New Trucks: Offer the latest technology, full manufacturer warranties, greater reliability, and often better fuel efficiency due to modern engine designs. You get peace of mind knowing it’s untouched and built to your exact specifications. However, the initial capital outlay is significantly higher.

- Used Trucks: Can be a cost-effective solution, allowing businesses to acquire necessary equipment at a fraction of the new price. This is particularly appealing for startups or those expanding their fleet on a budget. However, they come with higher risks of wear and tear, potentially unknown maintenance histories, and shorter lifespans. Pro tips from us: Always get a comprehensive third-party inspection for used trucks.

Based on my experience, for businesses that rely heavily on their fleet daily and cannot afford downtime, a new truck often justifies the higher upfront cost through reliability and warranty. For less intensive use or as an auxiliary vehicle, a thoroughly inspected used truck can be an excellent value.

2. Chassis and Engine: The Foundation of Power

The chassis is the backbone of your truck, and its strength dictates the vehicle’s durability and load-bearing capacity. Look for heavy-duty frames designed for the rigors of commercial hauling.

- Engine Power: Match the engine’s horsepower and torque to the gross vehicle weight rating (GVWR) and the typical loads you’ll be carrying. Underpowered trucks will struggle, consume more fuel, and wear out faster. Overpowered trucks might be overkill for lighter duties.

- Transmission Type: Automatic transmissions offer ease of operation and are preferred in stop-and-go urban environments. Manual transmissions provide more control and are often more fuel-efficient on long hauls, but require skilled drivers.

- Fuel Efficiency: With fluctuating fuel prices, a more fuel-efficient engine can lead to substantial long-term savings. Consider modern diesel engines with advanced emission controls.

3. Hydraulic System: The Heart of the Operation

The hydraulic system is what makes these trucks functional. Its power, reliability, and maintenance requirements are paramount.

- Pump Size and Pressure: Ensure the hydraulic pump is adequately sized for the lifting capacity required. A robust system will operate smoothly and efficiently without strain.

- Hose and Fitting Quality: High-quality hoses and fittings are essential to prevent leaks and system failures. Cheap components lead to costly downtime.

- Control System: Modern trucks feature ergonomic and intuitive controls, often with proportional valves for smoother operation. Test the controls during an inspection.

4. Container Capacity and Weight Rating (GVWR)

Understanding your payload requirements is non-negotiable.

- GVWR: The Gross Vehicle Weight Rating is the maximum operating weight of the truck, including the chassis, body, fuel, driver, and payload. Never exceed this limit.

- Payload Capacity: This is the maximum weight of the container and its contents that the truck can legally and safely carry. Factor in the weight of your heaviest anticipated loads, including debris, waste, or materials. Overloading is a common mistake that leads to premature wear, safety hazards, and legal penalties.

5. Body and Mechanism Manufacturer Reputation

While the truck chassis might be from a well-known brand like Freightliner or Peterbilt, the roll-off, hooklift, or skip loader mechanism often comes from a specialized body builder.

- Reputation for Quality: Research the body manufacturer’s reputation for durability, engineering, and customer support. Brands like Galbreath, Heil, Stellar, and Palfinger are well-regarded.

- Spare Parts Availability: Ensure that parts for the hydraulic system and body components are readily available. This minimizes downtime when repairs are needed.

6. Safety Features: Protecting Your Investment and People

Safety should always be a top priority. Modern container delivery trucks come with an array of features designed to protect operators and those around the vehicle.

- Braking Systems: Anti-lock Braking Systems (ABS) and electronic stability control are standard, but advanced systems like automatic emergency braking are becoming more common.

- Visibility Aids: Backup cameras, 360-degree cameras, and proximity sensors are invaluable, especially when maneuvering large trucks in busy areas.

- Lighting: Adequate work lights, strobe lights, and reflective tape enhance visibility, particularly during night operations or in low-light conditions.

- Operator Controls: Ergonomically designed controls that are easy to understand and operate reduce the risk of accidents.

7. Compliance and Regulations

Operating commercial vehicles comes with strict regulations.

- DOT Regulations: Ensure the truck complies with all Department of Transportation (DOT) regulations regarding weight limits, safety equipment, and driver qualifications.

- Local and State Laws: Be aware of specific local and state regulations concerning container hauling, noise limits, and environmental standards.

- Emissions Standards: Modern trucks must meet stringent emission standards. Older used trucks might require retrofits or might not be legal in certain areas.

8. Maintenance and After-Sales Support

A truck is only as good as its maintenance.

- Dealer Network: A strong dealer network for both the chassis and body manufacturer ensures access to certified technicians and genuine parts.

- Warranty: Understand the warranty coverage for both new and used vehicles (if applicable).

- Service Plans: Inquire about available service plans or preventative maintenance programs that can help extend the life of your vehicle and minimize unexpected breakdowns.

9. Budget and Financing: Making it Work

The total cost of ownership goes beyond the purchase price.

- Initial Cost: This includes the purchase price, taxes, and registration fees.

- Operational Costs: Factor in fuel, insurance, maintenance, tires, and driver wages.

- Return on Investment (ROI): How quickly will the truck pay for itself through increased efficiency, new contracts, or reduced manual labor?

- Financing Options: Explore various financing options, including commercial loans, leases, or lines of credit. Many dealerships offer in-house financing. For more detailed information on commercial vehicle financing, you might find valuable resources from trusted financial institutions like the Small Business Administration (SBA) at https://www.sba.gov/.

The Buying Process: Navigating the Market for Container Delivery Trucks For Sale

Once you’ve narrowed down your requirements, the actual purchasing process begins. This phase demands diligence and a keen eye for detail.

1. Researching Dealers and Sellers

Start by identifying reputable dealers specializing in commercial trucks or specific container delivery systems.

- Online Reviews: Check online reviews and testimonials for their customer service, transparency, and after-sales support.

- Industry Reputation: Ask for recommendations within your industry network.

- Inventory: See if they have a wide selection of container delivery trucks for sale that match your criteria.

2. Inspections and Test Drives: Don’t Skip This Step!

This is crucial, especially for used trucks.

- Thorough Visual Inspection: Check for rust, frame damage, fluid leaks, tire wear, and signs of previous accidents. Look underneath the truck, paying close attention to welds and structural integrity.

- Hydraulic System Check: Operate the roll-off, hooklift, or skip loader mechanism through its full range of motion. Listen for unusual noises, check for smooth operation, and inspect hydraulic hoses and cylinders for leaks or damage.

- Engine and Transmission: Listen for strange noises, check fluid levels, and look for smoke from the exhaust. During a test drive, ensure smooth shifting, adequate power, and proper braking.

- Cab Interior: Check all gauges, lights, HVAC, and power windows. Ensure the driver’s seat is comfortable and adjustable.

Pro tips from us: Bring a mechanic specializing in heavy-duty trucks to inspect any used vehicle you’re seriously considering. Their expertise can uncover hidden issues that might cost you thousands later.

3. Documentation and Legality

Before finalizing any purchase, scrutinize all paperwork.

- Title and Registration: Ensure the title is clear and transferable, and that the VIN matches all documents.

- Maintenance Records: For used trucks, comprehensive maintenance records are gold. They provide insight into the vehicle’s history and how well it was cared for.

- Warranty Information: Understand what’s covered, for how long, and what voids the warranty.

- Service History: A detailed service history can reveal patterns of issues or proactive maintenance.

4. Negotiation Strategies

Don’t be afraid to negotiate the price.

- Market Research: Know the fair market value of similar trucks.

- Be Prepared to Walk Away: If the deal isn’t right, don’t feel pressured.

- Consider Add-ons: Sometimes, negotiating for included accessories, an extended warranty, or discounted service can be more beneficial than a small price reduction.

Maximizing Your Investment: Operation and Maintenance

Acquiring the right truck is just the beginning. Proper operation and diligent maintenance are key to maximizing its lifespan, ensuring safety, and achieving optimal ROI.

1. Proper Training for Operators

A well-maintained truck can still be damaged or operated unsafely if the driver isn’t properly trained.

- Manufacturer Guidelines: Ensure all operators are thoroughly familiar with the truck’s specific operating procedures and safety protocols as outlined by the manufacturer.

- Hands-on Training: Provide extensive hands-on training for loading, unloading, driving with heavy loads, and emergency procedures.

- Certification: Consider professional training and certification programs for heavy equipment operators.

2. Routine Maintenance Schedule

Neglecting maintenance is a common mistake that leads to costly breakdowns.

- Pre-Trip Inspections: Implement daily pre-trip inspections covering tires, lights, fluid levels, brakes, and hydraulic system components. This catches minor issues before they become major problems.

- Fluid Checks and Changes: Regularly check and change engine oil, transmission fluid, hydraulic fluid, and coolant according to manufacturer recommendations. Hydraulic fluid contamination is a common culprit for system failures.

- Lubrication: Keep all moving parts, especially pivot points on the hydraulic system, properly greased to reduce wear and friction.

- Brake Inspections: Regularly inspect brake pads, drums, and air lines.

- Tire Care: Maintain proper tire pressure, rotate tires as needed, and replace worn tires promptly.

Common mistakes to avoid are neglecting routine hydraulic fluid checks, ignoring warning lights on the dashboard, and extending oil change intervals beyond manufacturer recommendations. These seemingly small oversights can lead to catastrophic failures and significant downtime. For deeper insights into maintaining your commercial fleet, you might want to explore our article on .

3. Technology Integration

Leverage modern technology to enhance efficiency and safety.

- Telematics and GPS: GPS tracking, fleet management software, and telematics systems can optimize routes, monitor driver behavior, track fuel consumption, and provide valuable diagnostic data.

- Onboard Scales: Integrated weighing systems ensure you never overload your truck, preventing fines and undue wear.

The Future of Container Delivery Trucks

The industry is continuously evolving, driven by demands for greater efficiency, sustainability, and automation.

- Electric and Hybrid Options: Manufacturers are investing heavily in electric and hybrid container delivery trucks to reduce emissions and operating costs. While still emerging, these will become more prevalent.

- Advanced Driver-Assistance Systems (ADAS): Features like adaptive cruise control, lane-keeping assist, and enhanced collision avoidance systems will further improve safety.

- Smart Logistics Integration: Trucks will become more connected, integrating seamlessly with logistics platforms for optimized scheduling, dynamic routing, and predictive maintenance.

Conclusion: Driving Your Business Forward with the Right Truck

Investing in container delivery trucks for sale is a strategic decision that can profoundly impact your business’s operational efficiency, profitability, and reputation. By understanding the different types, meticulously evaluating key factors, and committing to proper maintenance, you can acquire a powerful asset that serves your needs for years to come.

Remember, this isn’t just about buying a truck; it’s about investing in a solution that will streamline your operations, enhance your service delivery, and ultimately, drive your business success. Take your time, do your research, and make an informed choice that propels your company forward in the competitive landscape. If you’re looking to expand your fleet, consider exploring our comprehensive guide on .