Heavy Duty Work Trucks For Sale: Your Ultimate Guide to Finding the Perfect Powerhouse for Your Business

Heavy Duty Work Trucks For Sale: Your Ultimate Guide to Finding the Perfect Powerhouse for Your Business Lmctruck.Guidemechanic.com

In the demanding world of commercial operations, a heavy-duty work truck isn’t just a vehicle; it’s the backbone of your business, a mobile workshop, and an indispensable tool for productivity. From hauling immense loads across challenging terrains to serving as a specialized platform for complex tasks, these robust machines are engineered to tackle the toughest jobs with unwavering reliability. Choosing the right heavy-duty truck can significantly impact your operational efficiency, safety, and bottom line.

This comprehensive guide is meticulously crafted to navigate you through every aspect of acquiring heavy-duty work trucks for sale. We’ll delve into the diverse types available, crucial factors for selection, the buying process, and essential considerations to ensure you make an informed investment that propels your business forward. Whether you’re a seasoned fleet manager or a small business owner looking to expand, understanding these powerhouses is key to unlocking your full potential.

Heavy Duty Work Trucks For Sale: Your Ultimate Guide to Finding the Perfect Powerhouse for Your Business

Understanding Heavy Duty Work Trucks: More Than Just Muscle

Heavy-duty work trucks are a distinct class of commercial vehicles designed for intense applications that light-duty and medium-duty trucks simply cannot handle. Their primary characteristic is their Gross Vehicle Weight Rating (GVWR), which typically ranges from 26,001 pounds and above. This robust construction allows them to carry substantial payloads, tow heavy trailers, and accommodate specialized equipment bodies.

These trucks are the unsung heroes across a myriad of industries. In construction, they transport materials and machinery; in logistics, they move goods; and in utility services, they provide mobile platforms for critical infrastructure maintenance. Based on my experience, many businesses underestimate the critical role these vehicles play in their daily operations until they face a task that demands their specialized capabilities. Investing in the right heavy-duty truck means investing in uninterrupted workflow and expanded service offerings.

Types of Heavy Duty Work Trucks: Finding Your Specialized Solution

The world of heavy-duty work trucks is incredibly diverse, with each type engineered for specific vocational purposes. Understanding these distinctions is crucial for identifying the perfect match for your business needs. Pro tip from us: Don’t just pick a truck based on its look; delve into its intended function and specifications.

A. Dump Trucks

Dump trucks are synonymous with construction and demolition sites, renowned for their open-box bed that can be raised at the front to "dump" loose material. These materials often include sand, gravel, dirt, and demolition debris. Their hydraulic lifting mechanisms are incredibly powerful, allowing for quick and efficient material discharge.

They come in various configurations, such as standard dump trucks, tandem axle dumps, tri-axle dumps, and even articulated dump trucks for off-road use. The choice depends on the volume and weight of material to be transported, as well as the terrain conditions. Reliability and robust frame construction are paramount for these workhorses.

B. Flatbed Trucks

Flatbed trucks are versatile workhorses, characterized by an open, flat platform without sides or a roof. This design makes them ideal for transporting oversized, irregularly shaped, or extremely long cargo that wouldn’t fit into an enclosed trailer. Common loads include construction materials like lumber and steel beams, machinery, and pre-fabricated structures.

Their open nature requires careful load securement, often using chains, straps, and tarps to protect the cargo from the elements. Some flatbeds come with optional features like side rails or removable stakes for added cargo security. The strength of the chassis and suspension is critical for handling heavy, unevenly distributed loads.

C. Service & Utility Trucks

Service and utility trucks are essentially mobile workshops, indispensable for field technicians across various industries, including telecommunications, electrical, plumbing, and roadside assistance. These trucks are typically equipped with specialized compartments, toolboxes, and often a crane or liftgate. They allow technicians to carry all necessary tools, parts, and equipment directly to the job site.

The interior organization and accessibility of tools are key features, enhancing efficiency and reducing downtime. Many also incorporate generators and air compressors to power tools on location. Their robust build ensures they can navigate diverse environments while carrying substantial loads of equipment.

D. Refuse & Recycling Trucks

Refuse and recycling trucks are highly specialized vehicles designed for waste collection and disposal. They feature compaction mechanisms to maximize the volume of waste collected before needing to unload. These trucks are integral to municipal services and private waste management companies.

Configurations vary, including front-loaders, side-loaders, and rear-loaders, each suited for different collection methods and types of waste. The durability of the compaction system and the truck’s overall chassis are critical, as they operate in demanding, stop-and-go conditions daily. Investing in efficient models can significantly reduce operational costs and environmental impact.

E. Tow Trucks (Heavy-Duty Wreckers)

Heavy-duty tow trucks, often called wreckers, are specifically engineered for recovering and towing large commercial vehicles, buses, and heavy equipment. Unlike standard tow trucks, these giants boast powerful hydraulic booms, multiple winches, and robust under-reach systems capable of lifting and moving thousands of pounds.

They are essential for accident recovery, vehicle repossession, and transporting disabled heavy machinery. The strength of the chassis, engine, and towing apparatus is paramount for safe and effective operation. Specialized training for operators is also crucial due to the complexity and inherent risks involved.

F. Concrete Mixer Trucks

Concrete mixer trucks, commonly known as cement mixers, are vital for construction projects requiring ready-mix concrete. They consist of a revolving drum mounted on a heavy-duty chassis, keeping the concrete in a liquid state until it reaches the construction site. The drum’s continuous rotation prevents the concrete from setting.

These trucks must handle immense weight, as concrete is exceptionally dense. Therefore, robust engines, transmissions, and suspension systems are essential. The size of the drum dictates the volume of concrete they can carry, directly impacting project efficiency and scheduling.

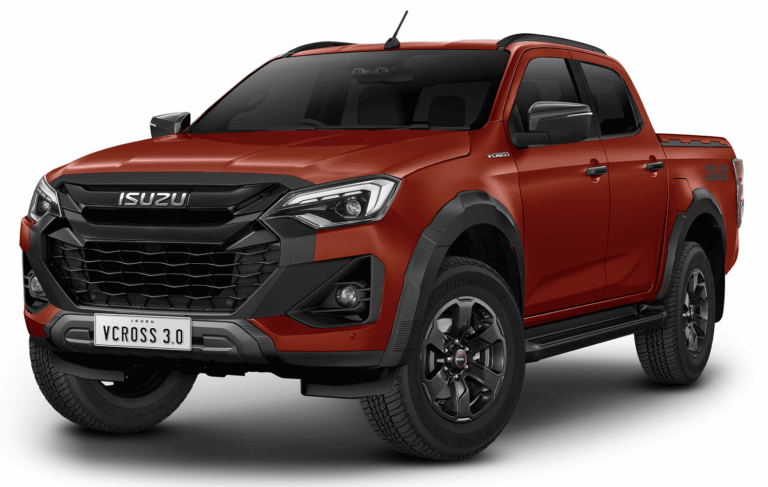

G. Vocational Chassis Trucks

Vocational chassis trucks are unique because they are sold as a "bare bones" platform, ready for customization with a wide array of specialized bodies and equipment. They provide the heavy-duty framework—engine, transmission, axles, and cab—upon which a specific vocational body can be mounted. This includes fire trucks, snowplows, street sweepers, and specialized utility vehicles.

This flexibility allows businesses to create a truly bespoke solution tailored to their exact operational requirements. The key here is selecting a chassis that offers sufficient GVWR, power take-off (PTO) options, and appropriate axle configurations for the intended upfit.

Key Factors to Consider When Buying Heavy Duty Work Trucks For Sale

Purchasing a heavy-duty work truck is a significant investment that requires careful consideration of numerous technical and operational factors. Overlooking any of these can lead to costly inefficiencies or even safety hazards.

A. Gross Vehicle Weight Rating (GVWR) & Gross Combined Weight Rating (GCWR)

The GVWR is the maximum operating weight of the truck as specified by the manufacturer, including the chassis, body, engine, fuel, accessories, driver, passengers, and cargo. The GCWR is the maximum allowable weight of the fully loaded truck and its attached trailer. Common mistakes to avoid are overlooking the GVWR requirements for your specific loads, which can lead to overloading fines, premature wear, and unsafe operation. Always ensure your chosen truck’s ratings exceed your maximum anticipated operational weight.

B. Engine & Drivetrain

The engine is the heart of your heavy-duty truck, dictating its power, torque, and fuel efficiency. Diesel engines are prevalent due to their high torque output and durability, essential for heavy hauling. Consider horsepower and torque figures relative to your typical loads and terrain. The transmission (manual or automatic) also plays a critical role. Automatic transmissions offer ease of operation, while manuals might provide more control and fuel efficiency for experienced drivers. Don’t forget the Power Take-Off (PTO) unit, which powers auxiliary equipment like cranes or pumps.

C. Chassis & Frame Strength

The chassis and frame form the skeletal structure of the truck, bearing all the weight and enduring operational stresses. Heavy-duty trucks feature robust, reinforced frames built from high-strength steel. Look for frames designed for the specific stresses of your intended application, such as double-framed sections for severe service. A strong chassis ensures longevity, stability, and the ability to safely support specialized bodies and heavy payloads.

D. Axle Configuration

Axle configuration refers to the number of axles and their arrangement, directly impacting the truck’s weight distribution and load-carrying capacity. Common configurations include single rear axles, tandem axles (two rear axles), and tri-axles (three rear axles). More axles generally mean higher GVWR and better weight distribution, which is crucial for handling extremely heavy or specialized loads. Consider also the axle ratings themselves and whether they are designed for the stresses of your operation.

E. Upfitting & Body Type

This factor is paramount for vocational trucks. The "upfit" refers to the specialized body or equipment mounted onto the chassis. Whether it’s a dump body, service body, crane, or refuse compactor, ensure the chosen chassis is compatible with the upfit’s weight, dimensions, and power requirements. Consider future customization needs and whether the chassis can accommodate them. Proper upfitting maximizes efficiency and safety.

F. Fuel Type

While diesel remains dominant for heavy-duty applications due to its efficiency and torque, alternative fuels like compressed natural gas (CNG) or even electric options are gaining traction. CNG offers lower fuel costs and emissions, though initial vehicle costs and fueling infrastructure can be hurdles. Evaluate your operational range, fueling access, and environmental goals when considering fuel type.

G. Cab Features & Comfort

Driver comfort and safety are often overlooked but directly impact productivity and retention. A comfortable cab with ergonomic seating, intuitive controls, and good visibility can reduce driver fatigue. Features like air conditioning, quality sound systems, and ample storage contribute to a better work environment. A well-rested driver is a safer and more efficient driver.

H. Safety Features

Modern heavy-duty trucks come equipped with a host of advanced safety features. Look for anti-lock braking systems (ABS), electronic stability control (ESC), traction control, and advanced driver-assistance systems (ADAS) like lane departure warnings and collision mitigation systems. These technologies significantly enhance safety for drivers and other road users, potentially reducing insurance costs and accident risks.

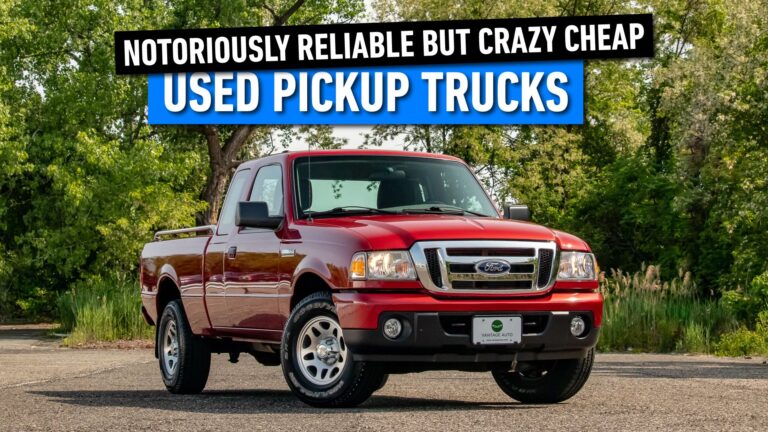

New vs. Used Heavy Duty Work Trucks: Weighing Your Options

The decision between purchasing a new or used heavy-duty work truck is a critical one, heavily influenced by budget, operational needs, and desired features. Each option presents distinct advantages and disadvantages. Based on my years in the industry, the choice often boils down to balancing upfront cost with long-term reliability and operational efficiency.

A. New Trucks

Pros:

- Latest Technology & Features: New trucks offer the most current engine designs, advanced safety systems, and ergonomic cab features, often translating to better fuel efficiency and driver comfort.

- Full Warranty: Comprehensive manufacturer warranties provide peace of mind against unexpected repairs, covering major components for several years or miles.

- Customization: You can order a new truck with exact specifications, including engine, transmission, axle configurations, and factory-installed upfits, perfectly tailored to your needs.

- Reliability: Brand new components mean fewer immediate concerns about wear and tear, leading to less downtime in the initial years.

Cons:

- Higher Upfront Cost: New trucks represent a significant capital investment, which might be prohibitive for smaller businesses or startups.

- Depreciation: Vehicles lose a substantial portion of their value the moment they leave the dealership, impacting your balance sheet.

B. Used Trucks

Pros:

- Cost Savings: Used heavy-duty trucks are significantly more affordable than their new counterparts, allowing businesses to acquire more capability for less money.

- Immediate Availability: Unlike new trucks that might have production lead times, used trucks are often available for immediate purchase and deployment.

- Proven Performance: A used truck’s history can provide insight into its real-world performance and durability.

- Lower Depreciation: The steepest depreciation curve has often passed, meaning the truck holds its value better over your ownership period.

Cons:

- Potential for Wear and Tear: Used trucks come with mileage and operational hours, meaning components might be closer to needing replacement.

- Limited Warranty (or None): Warranties on used trucks are typically shorter, less comprehensive, or non-existent, leaving you exposed to repair costs.

- Older Technology: Used trucks may lack the latest advancements in fuel efficiency, safety, or emissions technology.

- Unknown History: Unless meticulously documented, a truck’s past maintenance and operational history can be incomplete, potentially hiding future problems.

Where to Find Heavy Duty Work Trucks For Sale

Once you’ve determined your needs and budget, the next step is finding a reliable source for your heavy-duty work truck. The market offers several avenues, each with its own advantages.

A. Authorized Dealerships

Authorized dealerships specialize in new heavy-duty trucks from specific manufacturers (e.g., Peterbilt, Kenworth, Freightliner, Volvo). They also often have a selection of certified used trucks. Dealerships offer full manufacturer support, warranty services, parts, and often in-house financing. They are an excellent option for businesses seeking the latest models and comprehensive after-sales support.

B. Online Marketplaces

Online marketplaces have revolutionized the search for commercial vehicles, offering an unparalleled selection of heavy-duty work trucks for sale from sellers nationwide. Websites like TruckPaper.com, Commercial Truck Trader, and Ritchie Bros. Auctioneers’ marketplace list thousands of trucks, allowing you to filter by type, make, model, year, and price. This broad reach is ideal for finding specific configurations or niche vehicles. For more details on navigating online truck marketplaces, check out our guide on .

C. Auctions

Truck auctions, both live and online, can be a source of significant savings, but they come with higher risks. You might find great deals on heavy-duty trucks, but vehicles are often sold "as-is," with limited opportunities for thorough inspection. This option is best suited for experienced buyers who can quickly assess a truck’s condition or have access to professional inspectors.

D. Private Sellers

Purchasing from a private seller can offer direct negotiation and potentially lower prices, as there’s no dealership overhead. However, private sales typically lack warranties and the same level of consumer protection. Due diligence, including a detailed inspection and service history review, is paramount when dealing with private parties.

E. Fleet Sales & Government Auctions

Large corporations, rental companies, and government agencies regularly cycle out their heavy-duty fleets. These vehicles are often well-maintained, with comprehensive service records. Government auctions, in particular, can offer a diverse range of trucks that have been serviced to strict standards. This can be an excellent source for reliable used trucks.

The Buying Process: A Step-by-Step Approach

Acquiring a heavy-duty work truck requires a structured approach to ensure you make a sound investment. Following these steps can help mitigate risks and secure the best possible deal.

A. Define Your Needs & Budget

Before looking at any trucks, clearly outline your operational requirements. What specific tasks will the truck perform? What are the minimum GVWR, engine power, and payload capacities needed? Equally important, establish a realistic budget, including not just the purchase price but also financing costs, insurance, maintenance, and potential upfitting expenses.

B. Research & Comparison

With your needs defined, research different makes, models, and configurations that fit your criteria. Compare specifications, features, and pricing from various sellers. Read reviews, consult industry experts, and gather as much information as possible to narrow down your options.

C. Inspection (Pre-Purchase)

This is a non-negotiable step, especially for used trucks. Conduct a thorough visual inspection, checking for rust, frame damage, fluid leaks, tire wear, and proper functioning of all lights and accessories. More importantly, get a professional third-party inspection from a qualified heavy-duty mechanic. They can identify potential mechanical, electrical, or structural issues that might not be visible to the untrained eye. Pro tip from us: Always get a professional third-party inspection, even for a seemingly perfect truck. This can save you from significant repair costs down the line.

D. Test Drive

A comprehensive test drive is essential. Evaluate the truck’s performance, handling, braking, and overall feel. Pay attention to engine noise, transmission shifting, steering responsiveness, and any unusual vibrations or sounds. Test all auxiliary functions, such as PTOs, liftgates, or dump mechanisms, if applicable.

E. Financing & Insurance

Explore various financing options, including commercial loans, leases, or lines of credit. Compare interest rates, terms, and down payment requirements. Simultaneously, obtain quotes for commercial truck insurance, which can be substantial for heavy-duty vehicles. Ensure you understand coverage limits and liabilities.

F. Due Diligence (VIN Check, Service History)

For used trucks, always perform a VIN check to verify the vehicle’s history, including accident reports, odometer discrepancies, and previous ownership. Request detailed service and maintenance records from the seller. A well-documented history is a strong indicator of a well-cared-for truck.

G. Negotiation & Purchase

Once satisfied, negotiate the price and terms. Be prepared to walk away if the deal isn’t right. Ensure all paperwork is in order, including the bill of sale, title, and any warranty documents. Understand the terms of the sale fully before finalizing.

Essential Legal & Regulatory Considerations

Operating heavy-duty work trucks involves a complex web of legal and regulatory requirements. Compliance is not optional; it’s critical for safety, avoiding hefty fines, and maintaining your operating authority.

A. Commercial Driver’s License (CDL)

In most regions, operating heavy-duty work trucks requires a Commercial Driver’s License (CDL). The specific class of CDL (Class A, B, or C) depends on the truck’s GVWR, whether it’s towing a trailer, and the type of cargo. Ensure your drivers are properly licensed and endorsed for the specific vehicles they will operate.

B. DOT Regulations

The Department of Transportation (DOT) enforces stringent regulations for commercial motor vehicles. This includes hours of service (HOS) rules to prevent driver fatigue, mandatory pre-trip and post-trip inspections, and comprehensive vehicle maintenance records. Failure to comply can result in fines, out-of-service orders, and legal penalties.

C. Emissions Standards

Heavy-duty trucks are subject to strict emissions standards set by environmental agencies (e.g., EPA in the U.S.). Newer trucks incorporate advanced emissions control technologies. When purchasing, especially used trucks, ensure they meet current emissions regulations for your operating area. Non-compliance can lead to fines and operational restrictions.

D. Weight Restrictions & Permitting

State and local jurisdictions impose weight restrictions on roads and bridges. Heavy-duty trucks, especially when fully loaded, must adhere to these limits. Oversize or overweight loads may require special permits, which involve additional costs and routing restrictions. Always be aware of the specific regulations for your routes. For comprehensive details on federal trucking regulations, refer to the FMCSA website: .

Maintaining Your Investment: Ensuring Longevity and Performance

Proper maintenance is the cornerstone of maximizing the lifespan, reliability, and resale value of your heavy-duty work truck. Neglecting maintenance can lead to costly breakdowns, reduced efficiency, and safety hazards.

A. Regular Preventative Maintenance

Implement a rigorous preventative maintenance schedule based on manufacturer recommendations and operational demands. This includes routine oil and filter changes, fluid checks (transmission, coolant, hydraulic), tire rotations and inspections, and brake system checks. Proactive maintenance catches small issues before they escalate into major, expensive problems.

B. Specialized Component Checks

Many heavy-duty trucks have specialized components like PTOs, hydraulic systems for dump beds or cranes, and liftgates. These require specific maintenance routines, including lubrication, fluid changes, and operational checks. Ensure these critical systems are regularly inspected and serviced by qualified technicians.

C. Driver Training

Well-trained drivers who understand the proper operation and limitations of their heavy-duty truck can significantly extend its life. Training should cover safe operating procedures, load securement, pre-trip inspections, and reporting any issues promptly. This not only enhances safety but also reduces wear and tear on the vehicle. Learn more about cost-effective maintenance strategies in our article: .

Customization and Upgrades: Tailoring Your Truck for Peak Efficiency

Even after purchase, heavy-duty work trucks can be further optimized through customization and upgrades. These enhancements can boost productivity, improve safety, and extend the vehicle’s utility.

A. Specialized Bodies & Attachments

Many businesses invest in additional specialized bodies or attachments post-purchase. This could include adding a new crane, an advanced liftgate, a custom tool storage system, or specialized snowplow equipment. These modifications should always be performed by certified upfitters to ensure safety and structural integrity.

B. Telematics & GPS Systems

Integrating telematics and GPS tracking systems provides invaluable data for fleet management. These systems offer real-time location tracking, fuel consumption monitoring, driver behavior analysis, and diagnostic alerts. This data can lead to improved routing efficiency, reduced fuel costs, and better overall operational control.

C. Safety Enhancements

Beyond standard features, additional safety upgrades can include extra lighting, specialized mirrors, backup cameras, or even advanced sensor systems to detect obstacles in blind spots. Investing in these enhancements protects your drivers, your vehicle, and your reputation.

D. Comfort & Ergonomics

Upgrading cab features like premium seating, improved climate control, or sound insulation can significantly enhance driver comfort, especially for long hauls. A more comfortable driver is a more alert and productive driver, which translates to better overall performance and reduced fatigue-related incidents.

Conclusion

The journey to finding the ideal heavy-duty work truck for sale is a significant undertaking, but with the right knowledge and a methodical approach, it becomes a strategic investment that can transform your business operations. From understanding the nuanced differences between various truck types to meticulously considering financing, regulations, and ongoing maintenance, every step is crucial.

By focusing on your specific needs, conducting thorough research, and prioritizing a comprehensive inspection, you can confidently acquire a powerful, reliable, and efficient heavy-duty truck. Remember, this isn’t just about buying a vehicle; it’s about empowering your business with the ultimate workhorse that will serve you faithfully for years to come, ensuring productivity, safety, and sustained growth. Start your search today with confidence, knowing you’re equipped with the insights to make the best decision for your future.