Unveiling the Backbone of Commerce: A Deep Dive into Truck Body Cargo Names

Unveiling the Backbone of Commerce: A Deep Dive into Truck Body Cargo Names Lmctruck.Guidemechanic.com

In the bustling world of logistics and transportation, trucks are more than just vehicles; they are specialized tools, each designed with a unique purpose to carry the diverse cargo that fuels our economy. From the clothes on our backs to the food on our tables, and the materials that build our cities, understanding the specific "truck body cargo names" is crucial for anyone involved in moving goods. This isn’t just about identifying a truck; it’s about optimizing efficiency, ensuring safety, and making informed decisions that impact bottom lines.

As an expert blogger and professional SEO content writer with extensive experience in the logistics sector, I’ve seen firsthand how critical this knowledge is. Choosing the right truck body for the job isn’t merely a preference; it’s a strategic decision that affects everything from fuel consumption and loading times to cargo integrity and regulatory compliance.

Unveiling the Backbone of Commerce: A Deep Dive into Truck Body Cargo Names

This comprehensive guide will unravel the intricacies of various truck body cargo names, exploring their functions, ideal cargo, and the unique advantages they offer. Our goal is to provide you with a pillar of knowledge, equipping you to navigate the complex landscape of commercial transport with confidence.

The Foundation: Why Understanding Truck Body Cargo Names Matters

Before we delve into specific types, let’s establish why this knowledge is indispensable. The world of trucking is incredibly diverse, with countless variations tailored to specific needs. Misidentifying or misusing a truck body can lead to a cascade of problems.

Based on my experience, a common pitfall for new logistics managers or business owners is assuming "a truck is a truck." This oversight can result in significant financial losses due to damaged goods, inefficient loading, increased operational costs, and even legal penalties. Proper selection ensures your cargo arrives safely, on time, and within budget.

Moreover, a deep understanding of these classifications helps in effective fleet management, strategic planning, and even negotiating better rates with carriers. It empowers you to speak the same language as industry professionals, fostering trust and clarity in your operations.

Deconstructing the Fleet: A Comprehensive Guide to Truck Body Cargo Names

Let’s embark on our journey to explore the most prevalent and specialized truck body cargo names, detailing their unique characteristics and applications. Each type has been engineered for optimal performance with specific kinds of freight.

1. The Versatile Dry Van Truck Body

The dry van is arguably the most common and recognizable truck body on the road, often simply referred to as a "box truck" or "enclosed trailer." This fully enclosed, non-temperature-controlled trailer protects cargo from weather, theft, and road debris. Its design offers maximum versatility for a wide array of goods.

Common Cargo: Dry vans transport a vast variety of general freight that doesn’t require refrigeration or special handling for temperature. This includes packaged goods, electronics, textiles, non-perishable foods, furniture, and consumer products. If it can fit through the doors and doesn’t need to be kept cold or hot, a dry van is likely its carrier.

Key Features: These bodies typically feature swing-out rear doors or roll-up doors, and solid side walls. They are designed for palletized freight, often loaded and unloaded via forklifts at loading docks. Their robust construction ensures cargo security and protection from external elements.

Advantages: The primary advantages include excellent weather protection, enhanced security against theft, and broad applicability for diverse cargo. They are also relatively economical to operate compared to specialized trailers.

Pro tips from us: Always verify the interior dimensions and weight capacity, especially for dense loads. A common mistake to avoid is overloading, which can lead to safety hazards and legal issues.

2. The Robust Flatbed Truck Body

In stark contrast to the enclosed dry van, the flatbed truck body is an open platform without sides or a roof. This design is specifically engineered for cargo that is oversized, irregularly shaped, or requires loading from the top or sides. Its simplicity belies its incredible utility in heavy industries.

Common Cargo: Flatbeds are indispensable for construction materials such as lumber, steel beams, pipes, and machinery. They also haul pre-fabricated structures, large equipment, tires, and even vehicles that wouldn’t fit in an enclosed trailer. Essentially, anything too big or awkward for a box.

Key Features: The defining feature is the completely open, flat deck. Cargo is secured using straps, chains, tarps, and specialized tie-downs. Many flatbeds come with removable side stakes or bulkheads for added flexibility and safety.

Advantages: Unrestricted loading and unloading access from any side or overhead is a major benefit. They can accommodate extremely large and heavy items that other trailers cannot. This flexibility makes them essential for many industrial and construction projects.

Common mistakes to avoid are: Inadequate securement of cargo, leading to shifting loads or items falling off. Based on my experience, investing in proper training for securement techniques and high-quality tie-downs is paramount for flatbed operations.

3. The Chilled Refrigerated (Reefer) Truck Body

When cargo needs to stay cool, or even frozen, the refrigerated truck body – commonly known as a "reefer" – steps in. These are essentially mobile refrigerators or freezers, crucial for preserving temperature-sensitive goods during transit. They play a vital role in the food and pharmaceutical industries.

Common Cargo: Reefers primarily transport perishable goods such as fresh produce, meat, dairy products, frozen foods, and flowers. They are also used for pharmaceuticals, chemicals, and other items that require precise temperature control to maintain their integrity.

Key Features: A reefer trailer is an insulated box equipped with a refrigeration unit, typically mounted on the front. This unit circulates cold air throughout the trailer, maintaining a consistent internal temperature. Some advanced reefers can even maintain different temperature zones within the same trailer.

Advantages: The ability to maintain precise temperature control is the obvious key advantage, preventing spoilage and ensuring product quality. This is critical for public health and safety standards.

Pro tips from us: Regular maintenance of the refrigeration unit is non-negotiable. A common mistake is neglecting preventative checks, which can lead to costly breakdowns and ruined cargo. Always pre-cool the trailer before loading temperature-sensitive items.

4. The Mighty Dump Truck Body

The dump truck body is designed for hauling and automatically discharging loose materials. It’s a workhorse in construction, mining, and landscaping, instantly recognizable by its open-box bed that can be raised at the front to "dump" its contents.

Common Cargo: Dump trucks are primarily used for bulk materials such as sand, gravel, dirt, asphalt, demolition debris, and aggregates. They are fundamental to road building, excavation, and site preparation projects.

Key Features: The most distinctive feature is the hydraulic lifting mechanism that tilts the bed to empty its load. The bed itself is typically made of heavy-duty steel to withstand abrasive materials and impacts. Different configurations exist, including standard dumps, articulated dumps, and transfer dumps.

Advantages: Efficient and rapid unloading of bulk materials saves significant time and labor on job sites. Their robust construction allows them to handle extremely heavy and abrasive loads.

Common mistakes to avoid are: Overloading the truck beyond its weight capacity, which compromises stability and can damage the vehicle or road infrastructure. Always ensure the bed is fully lowered before driving off.

5. The Specialized Tanker Truck Body

Tanker trucks are highly specialized vehicles designed to transport liquids, gases, or dry bulk materials in a cylindrical or elliptical tank. Their design varies significantly based on the specific substance they carry, prioritizing safety and containment.

Common Cargo: This includes fuel (gasoline, diesel), chemicals (acids, solvents), milk, water, liquid fertilizers, asphalt, and even dry bulk materials like flour, sugar, or cement in pneumatic tankers. The type of material dictates the tank’s construction.

Key Features: The most prominent feature is the large, usually cylindrical tank. Tankers are often compartmentalized to carry different liquids or to prevent sloshing. They feature specialized valves, pumps, and safety systems for loading and unloading, often made from stainless steel or aluminum.

Advantages: Safe and efficient transport of large volumes of liquid or granular materials. The enclosed nature prevents spillage and contamination, critical for hazardous materials.

Pro tips from us: Understanding HazMat regulations and driver endorsements is absolutely critical for tanker operations. Based on my years in logistics, compliance with placards, safety protocols, and driver training for specific cargo types is non-negotiable.

6. The Flexible Curtainside Truck Body (Tautliner)

The curtainside truck body, often called a "tautliner," offers a unique blend of the dry van’s weather protection and the flatbed’s side-loading accessibility. Its sides are made of heavy-duty, retractable curtains, providing quick and easy access to cargo.

Common Cargo: Curtainsides are excellent for palletized goods, machinery, building materials, and anything that benefits from side loading but still requires protection from the elements. They are particularly popular in Europe for general freight.

Key Features: The defining characteristic is the PVC-coated fabric "curtains" that slide open along a rail, revealing the full length of the trailer bed. These curtains are tensioned to create a taut, weather-resistant enclosure. They often have a solid roof and rear doors like a dry van.

Advantages: The main benefit is the ease of loading and unloading cargo from the sides using forklifts, making operations much faster than a traditional dry van for certain types of freight. It combines weather protection with accessibility.

Common mistakes to avoid are: Not properly tensioning the curtains before transit, which can lead to flapping, damage, and potential cargo exposure. Always ensure all latches are secure.

7. The Practical Stake Bed Truck Body

A stake bed truck body is essentially a flatbed with removable stakes or panels around its perimeter. This design offers the flexibility of an open flatbed while providing some containment for loose or stacked items.

Common Cargo: Stake beds are frequently used for landscaping materials, nursery plants, construction supplies that need some side support (e.g., bricks, bags of cement), and general freight that benefits from being contained but doesn’t require a fully enclosed space.

Key Features: The key feature is the series of vertical "stakes" or panels that fit into pockets along the edges of the flatbed. These can be removed to convert the truck into a traditional flatbed. The bed itself is usually flat and robust.

Advantages: Offers greater versatility than a standard flatbed by providing containment for cargo that might otherwise roll off. It’s easy to adapt for different load types by adding or removing stakes.

Pro tips from us: While the stakes provide containment, they don’t offer full security or weather protection. Always tarp goods that need protection from rain or dust.

8. The Essential Service Body (Utility Body)

The service body, also known as a utility body, is a highly specialized truck body designed to carry tools, equipment, and parts for mobile service professionals. These bodies are essentially rolling workshops, critical for tradespeople and field technicians.

Common Cargo: Not cargo in the traditional sense, but rather a mobile inventory of tools, spare parts, equipment (generators, compressors), and materials specific to a particular trade, such as plumbing, electrical work, HVAC, or telecommunications.

Key Features: Service bodies are characterized by multiple external compartments with locking doors, providing secure and organized storage. They often include integrated shelving, drawers, and sometimes a ladder rack or crane. They are typically mounted on a pickup truck chassis.

Advantages: Exceptional organization and accessibility for tools and parts, saving technicians time and improving efficiency on job sites. Enhanced security for valuable equipment.

Common mistakes to avoid are: Overloading compartments, which can damage the body or affect vehicle handling. Regularly inventorying and organizing tools prevents lost time searching for items.

9. The Efficient Roll-Off Container Truck Body

A roll-off truck body is designed to transport large, open-top containers that can be "rolled off" and left at a site for loading, and then "rolled on" for transport when full. This system is highly efficient for waste management and material hauling.

Common Cargo: Primarily used for construction and demolition debris, municipal waste, scrap metal, recyclables, and large volumes of non-compactable waste.

Key Features: The truck features a hydraulic hoist system with rails that allow a specialized container to be loaded or unloaded onto the ground. The containers themselves come in various sizes (e.g., 10-yard, 20-yard, 40-yard) and are open-topped.

Advantages: Allows for efficient waste collection and disposal, as multiple containers can be rotated at different sites using a single truck. Reduces loading time and improves site cleanliness.

Pro tips from us: Always ensure the container is properly latched and secured to the truck before driving. Overfilling containers is a common mistake that can lead to spills and fines.

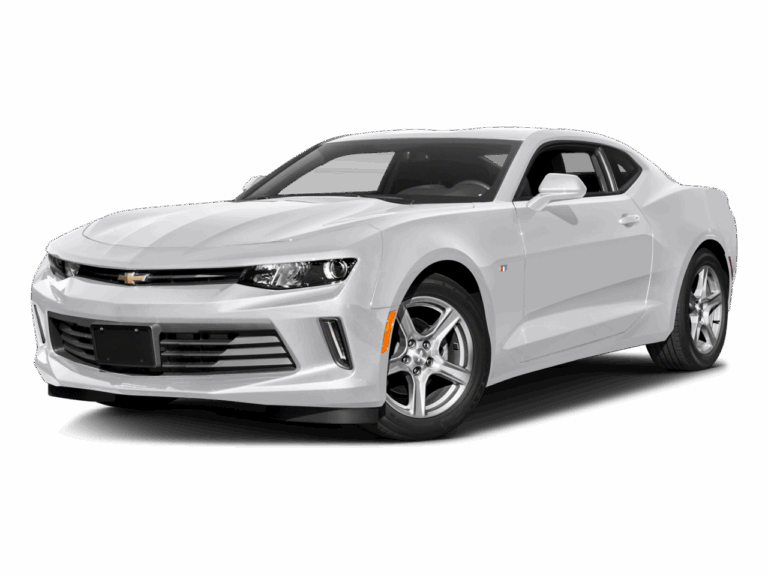

10. The Specialized Car Carrier / Auto Hauler

Car carrier truck bodies are specifically engineered to transport multiple vehicles simultaneously. These are complex structures designed for safe and secure loading, transport, and unloading of cars, trucks, and other automobiles.

Common Cargo: New cars from manufacturing plants to dealerships, used cars for auctions or individual transport, luxury vehicles, and classic cars.

Key Features: Auto haulers feature multiple ramps and decks (often adjustable hydraulically) to maximize the number of vehicles carried. They include sophisticated securement systems to prevent movement during transit. Open carriers are most common, but enclosed car carriers are used for high-value or delicate vehicles.

Advantages: Highly efficient for moving multiple vehicles, reducing individual transport costs. Specialized design ensures vehicles are transported without damage.

Based on my experience: Driver skill in loading and securing vehicles is paramount. One common mistake is improper weight distribution, which can severely impact vehicle stability.

11. The Heavy-Duty Lowboy / Removable Gooseneck Trailer (RGN)

Lowboy trailers, especially those with Removable Goosenecks (RGNs), are designed for transporting extremely tall or heavy equipment that would exceed legal height limits on a standard flatbed. Their defining characteristic is a very low deck height.

Common Cargo: Oversized construction equipment (excavators, bulldozers), agricultural machinery, large industrial components, and other super-heavy or tall loads.

Key Features: The RGN feature allows the front of the trailer (the gooseneck) to be detached, enabling the equipment to be driven directly onto the main deck from the front. This makes loading very large machinery much easier and safer. The main deck is very close to the ground.

Advantages: Crucial for legal and safe transport of extremely tall and heavy loads. The RGN design simplifies the loading and unloading process for self-propelled equipment.

Common mistakes to avoid are: Not properly securing the gooseneck after reattachment, or miscalculating clearances. Based on my years in heavy-haul logistics, meticulous route planning and permitting are absolutely essential for lowboy operations.

12. The Flexible Step Deck / Drop Deck Trailer

Similar to a flatbed but with a two-level deck, the step deck (or drop deck) trailer offers increased versatility for hauling taller loads. It features an upper deck over the kingpin and a lower, longer main deck.

Common Cargo: Taller equipment, machinery, large crates, or anything that might be too tall for a standard flatbed but doesn’t require the extreme low clearance of a lowboy. It bridges the gap between flatbeds and lowboys.

Key Features: The "step" in the deck allows for cargo with a greater height profile than a traditional flatbed can accommodate, while still maintaining the open-air flexibility. Cargo is secured similarly to a flatbed using straps and chains.

Advantages: Greater height flexibility compared to a flatbed, allowing for taller loads to be transported legally. Still offers easy loading and unloading from the sides or top.

Pro tips from us: Always consider the combined height of the trailer and cargo when planning routes to avoid overhead obstructions.

Beyond the Basics: Specialized Truck Bodies and Their Niche Roles

While the above covers the most common types, the world of truck bodies is vast. There are countless specialized designs tailored for very specific industries:

- Log Trucks: Equipped with strong bunks and binders to haul timber.

- Grain Hoppers: Trailers with sloped sides and bottom gates for gravity unloading of agricultural grains.

- Livestock Trailers: Designed with ventilation and ramps for humane transport of animals.

- Boom Trucks/Crane Trucks: Trucks integrated with hydraulic cranes for lifting and placing heavy objects.

- Expediter Vans: Smaller, often non-CDL required, cargo vans or straight trucks designed for urgent, time-critical deliveries.

These niche bodies underscore the principle that for every specialized cargo, there’s likely a specially engineered truck body to transport it efficiently and safely.

Navigating Regulations and Safety with the Right Truck Body

Choosing the correct truck body isn’t just about functionality; it’s deeply intertwined with regulatory compliance and safety. Each body type has specific weight distribution requirements, securement standards, and sometimes, even licensing or permitting stipulations.

Based on my years in logistics, compliance is non-negotiable. Federal and state regulations (like those from the Department of Transportation or FMCSA in the US) dictate maximum weights, dimensions, and securement methods. Ignorance is not an excuse and can lead to hefty fines, delays, and catastrophic accidents. For instance, securing a load on a flatbed requires meticulous attention to detail and adherence to specific tiedown ratios, which is vastly different from simply closing the doors on a dry van.

Understanding these nuances is a hallmark of an expert operator and a responsible business. For more detailed information on specific regulations, I recommend consulting official sources like the Federal Motor Carrier Safety Administration (FMCSA) website.

Making the Smart Choice: Key Factors When Selecting a Truck Body

When considering which truck body cargo name best suits your operational needs, a systematic approach is essential. Here are the key factors to evaluate:

- Type of Cargo: Is it perishable, oversized, hazardous, or general freight? This is the most fundamental question.

- Cargo Dimensions & Weight: Will it fit within legal height, width, and weight limits?

- Loading/Unloading Method: Does it require dock loading, crane loading, side access, or roll-on/roll-off capabilities?

- Environmental Protection: Does the cargo need protection from weather, temperature fluctuations, or theft?

- Frequency & Distance: Is it for short-haul, frequent deliveries, or long-haul, infrequent runs?

- Budget & Operational Costs: Consider initial purchase price, maintenance, fuel efficiency, and specialized equipment needs.

- Regulatory Compliance: Ensure the body type and your planned operations meet all local, state, and federal regulations.

- Durability & Longevity: For heavy-duty applications, investing in robust construction pays off in the long run.

Pro tips for new buyers: Don’t just look at the upfront cost. Consider the total cost of ownership, including maintenance, potential downtime, and resale value. A cheaper body that constantly needs repairs or limits your cargo options will end up costing more. For more insights on fleet management, you might find our article on Optimizing Your Commercial Fleet: A Guide to Efficiency and Cost Savings helpful.

Conclusion: Empowering Your Logistics Decisions

The world of "truck body cargo names" is rich with specialized designs, each playing a critical role in the global supply chain. From the ubiquitous dry van to the specialized lowboy, understanding these distinctions is more than just academic knowledge; it’s a strategic imperative for efficiency, safety, and profitability in transportation.

By delving deep into the functions and features of each truck body, we hope to have equipped you with the expertise needed to make informed decisions for your logistics needs. Remember, the right truck body isn’t just a container; it’s a precisely engineered solution that keeps the wheels of commerce turning smoothly.

What are your experiences with different truck body types? Share your insights and challenges in the comments below! If you’re looking to expand your knowledge further, perhaps our guide on Navigating Trucking Regulations: Essential Compliance for Fleet Managers could be your next read.