Unleash the Beast: Your Definitive Guide to the Jeep 4.0 to 5.0 Stroker Kit

Unleash the Beast: Your Definitive Guide to the Jeep 4.0 to 5.0 Stroker Kit Lmctruck.Guidemechanic.com

The Jeep 4.0L inline-six engine is more than just a power plant; it’s a legend. Renowned for its bulletproof reliability, impressive low-end torque, and straightforward design, this engine has powered countless Jeeps through trails, over rocks, and across continents. But what if you crave even more? What if you want to transform that venerable 4.0L into a true torque monster, pushing the boundaries of its performance?

Enter the Jeep 4.0 to 5.0 Stroker Kit. This isn’t just an upgrade; it’s a complete metamorphosis that significantly boosts your Jeep’s displacement, leading to a dramatic increase in horsepower and, more importantly, earth-shattering torque. For serious off-roaders, those running larger tires, or anyone simply yearning for exhilarating performance, a 4.0 stroker build is a game-changer.

Unleash the Beast: Your Definitive Guide to the Jeep 4.0 to 5.0 Stroker Kit

In this ultimate guide, we’re diving deep into the world of the Jeep 4.0 to 5.0 Stroker Kit. We’ll explore what it is, why it’s so effective, the critical components involved, and how to embark on this epic engine transformation. Our goal is to equip you with the knowledge to confidently plan and execute your own high-performance Jeep engine build, ensuring it meets your needs and exceeds your expectations.

The Enduring Legacy of the Jeep 4.0L Engine: A Foundation Worth Building On

Before we delve into the magic of the stroker kit, let’s take a moment to appreciate the engine that serves as its canvas. The AMC-derived 4.0L High Output (HO) inline-six, found in popular models like the Jeep Cherokee XJ, Wrangler TJ/YJ, and Grand Cherokee ZJ, earned its reputation for a reason. Its robust cast-iron block, gear-driven camshaft, and relatively undersquare design (stroke longer than bore) made it an inherently strong and torquey engine right out of the factory.

This engine’s simplicity and ruggedness made it a favorite among enthusiasts. It could take a beating and keep going, often outlasting the vehicle around it. Its ample low-end torque was perfect for crawling over obstacles, a characteristic that modern, smaller displacement engines often struggle to replicate.

However, even legends have their limits. When you add heavy armor, larger tires, and more gear to your Jeep, the stock 4.0L can start to feel a bit anemic. This is precisely where the allure of a Jeep stroker engine comes into play, building upon an already fantastic foundation to unlock truly exceptional power.

What Exactly is a Jeep 4.0 to 5.0 Stroker Kit? Understanding the Core Concept

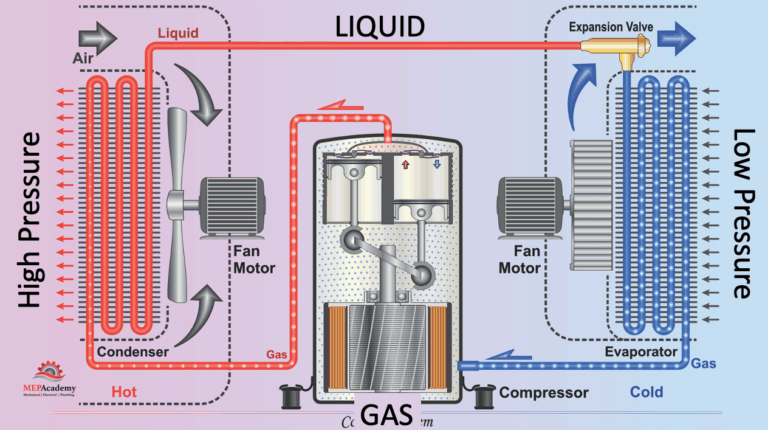

At its heart, a Jeep 4.0 to 5.0 Stroker Kit is a collection of components designed to increase the displacement of your 4.0L engine. Think of it as giving your engine bigger lungs. By increasing the volume of air and fuel it can ingest and combust, you inherently generate more power. The "5.0" in the name isn’t a literal 5.0 liters (though some extreme builds might approach it); it generally refers to increasing the displacement from 4.0L to somewhere in the 4.6L to 4.9L range, which is a substantial jump.

The primary method for achieving this increased displacement is by lengthening the engine’s stroke. This means the piston travels a greater distance up and down within the cylinder bore. To achieve this longer stroke, a specific crankshaft is used, typically sourced from an older AMC 4.2L inline-six engine (found in CJs and YJs) or an aftermarket equivalent. This crankshaft has a longer throw, pushing the pistons further.

Because the crankshaft’s throw is longer, the connecting rods and pistons also need to be replaced. Shorter connecting rods are usually paired with specific pistons to ensure they don’t hit the cylinder head at the top of their travel or protrude too far at the bottom. The result is a larger combustion chamber volume, allowing for more potent combustion events and, consequently, a significant boost in both torque and horsepower. It’s a mechanical marvel that re-engineers the very heart of your Jeep.

Why Go Stroker? Unlocking Unprecedented Power for Your Jeep

The decision to install a Jeep Stroker Kit isn’t made lightly, but the benefits are incredibly compelling for the right owner. The transformation in performance is palpable, making your Jeep feel like an entirely different beast.

First and foremost, you gain significant torque and horsepower. While the exact numbers vary based on components and tuning, it’s common to see horsepower figures jump from the stock 190hp to well over 250-300hp, and torque soar from 220 lb-ft to over 300-350 lb-ft. This power is not just for bragging rights; it translates directly into tangible performance improvements.

For off-roading, that extra low-end grunt is invaluable. Climbing steep grades, navigating rocky terrain, or powering through mud becomes considerably easier. Your engine won’t have to work as hard, reducing strain and improving control. This means less shifting and a more confident approach to challenging obstacles.

On the pavement, a stroker engine dramatically improves daily drivability. Merging onto highways, passing slower traffic, and simply maintaining speed with larger tires becomes effortless. You’ll find your Jeep accelerates with a newfound urgency, making it far more enjoyable to drive both on and off the road.

Finally, for those running larger tires (33 inches and up), a stroker kit effectively negates the power loss associated with increased rotating mass. It allows your Jeep to spin those big tires with authority, restoring and even surpassing the performance of a stock Jeep on smaller tires. It truly breathes new life into an aging platform, giving you a competitive edge and an incredibly satisfying driving experience.

Components of a High-Quality Jeep Stroker Kit: What You Need to Know

Building a successful 4.0 Stroker requires careful selection of components. This isn’t a one-size-fits-all endeavor; the parts you choose will dictate the final displacement, compression ratio, and overall character of your engine. Understanding each component’s role is crucial for a successful build.

- Crankshaft: This is the heart of the stroker. The most common choice is the crankshaft from an AMC 4.2L (258ci) engine, often found in 1971-1990 Jeep CJs and YJs. It has a longer stroke (3.895 inches) compared to the 4.0L (3.414 inches). This crank typically needs to be machined and balanced for optimal performance and longevity. Aftermarket stroker cranks are also available, offering improved metallurgy and sometimes different stroke lengths for even larger displacements.

- Connecting Rods: With a longer-stroke crankshaft, you need shorter connecting rods to prevent the pistons from hitting the cylinder head. Common choices include rods from a Chevy 4.3L V6 (5.850 inches long) or various aftermarket options specifically designed for stroker applications. The length must be precise to achieve the desired piston deck height.

- Pistons: These are critical for setting the compression ratio and working with the new rod/crank combination. Stroker pistons are usually custom-made or specific off-the-shelf options designed to match the shorter rods and longer stroke. They often feature specific pin heights and dish volumes to fine-tune the compression ratio for pump gas compatibility or forced induction if desired.

- Cylinder Head: While not strictly part of the "kit," upgrading the cylinder head is highly recommended for maximizing stroker performance. Porting and polishing the intake and exhaust runners improves airflow, larger valves increase flow potential, and stiffer valve springs prevent valve float at higher RPMs. Aftermarket performance heads are also available and offer significant gains.

- Camshaft: This is arguably one of the most critical components for unlocking the full potential of your new displacement. A stock 4.0L camshaft is simply not optimized for a larger engine. A performance camshaft, designed specifically for a stroker, will have different lift, duration, and lobe separation angles to take advantage of the increased airflow and displacement, boosting both torque and horsepower across the RPM range.

- Fuel System Upgrades: More air and bigger bang require more fuel. Larger fuel injectors (typically 24-28 lbs/hr for a naturally aspirated stroker) and sometimes a higher-flow fuel pump are necessary to prevent leaning out the engine, which can cause catastrophic damage.

- Exhaust System: To efficiently expel the increased volume of exhaust gases, an upgraded exhaust system is a must. A performance header (long tube is often preferred for torque), a larger diameter exhaust pipe (2.5 inches is common), and a high-flow catalytic converter and muffler will reduce backpressure and improve scavenging.

- Engine Management (ECU Tuning): This cannot be stressed enough – proper ECU tuning is absolutely essential. The stock computer is calibrated for a 4.0L engine; it will not correctly fuel and time a stroker. Custom tuning ensures the air-fuel ratio is optimal, timing is advanced appropriately, and all engine parameters are correctly managed for maximum power, efficiency, and longevity.

- Gaskets and Bearings: Every new engine build requires a complete set of high-quality gaskets, main bearings, rod bearings, and thrust bearings. Don’t cut corners here; these small components are vital for sealing and smooth operation.

Pro tips from us: When selecting components, research is key. Compatibility between parts (crank, rods, pistons, cam) is paramount. Don’t mix and match without consulting experienced builders or manufacturers. Investing in quality components from reputable brands will save you headaches and money in the long run. Skimping on parts is a common mistake that leads to premature failure and disappointment.

The Build Process: A Step-by-Step Overview (Simplified)

Building a Jeep 4.0 Stroker is a significant undertaking that requires mechanical aptitude, specialized tools, and meticulous attention to detail. While we can’t cover every nuance here, this overview provides a roadmap for the journey.

- Engine Removal and Disassembly: The first step is to carefully remove the 4.0L engine from your Jeep. Once on an engine stand, it’s completely disassembled. Every bolt, every component, is removed and inspected.

- Block Preparation and Machining: The bare block is sent to a reputable machine shop. Here, it will be thoroughly cleaned, hot-tanked, and inspected for cracks. The cylinders are then bored and honed to the new piston size, ensuring perfect roundness and a proper crosshatch for piston ring seating. The deck surface is usually "trued" or decked to ensure it’s perfectly flat for head gasket sealing. Line boring the main bearing bores might also be necessary, especially if using a different crankshaft.

- Crankshaft Preparation and Balancing: The 4.2L crankshaft (or aftermarket equivalent) will also go to the machine shop. It needs to be inspected, ground to spec (if needed), and critically, balanced with the new connecting rods and pistons. Proper balancing prevents excessive vibration, reduces wear, and is vital for engine smoothness and longevity.

- Engine Assembly: This is where your stroker truly comes to life.

- Install Main Bearings and Crankshaft: The crankshaft is carefully installed into the block, ensuring proper bearing clearances are measured and met.

- Install Camshaft and Lifters: The new performance camshaft is installed, followed by new lifters.

- Assemble Rods and Pistons: The new connecting rods and pistons are assembled. Piston rings are carefully gapped and installed.

- Install Piston/Rod Assemblies: Each piston and rod assembly is carefully installed into its respective cylinder, ensuring proper orientation and lubrication. Rod bearing clearances are measured and torqued to spec.

- Oil Pump and Pickup: A new, high-volume oil pump is often recommended and installed.

- Timing Chain and Cover: The timing chain, gears, and timing cover are installed.

- Cylinder Head Installation: The prepared cylinder head (with new valves, springs, etc.) is installed with a new head gasket and torqued down in the correct sequence.

- Rocker Arms and Pushrods: The valvetrain components are installed and adjusted.

- Accessory Installation: All external components like the intake manifold, exhaust manifold, alternator, power steering pump, water pump, and fuel injectors are reinstalled.

- Engine Re-installation and Initial Startup: The completed stroker engine is carefully re-installed into your Jeep. All fluids are topped off, and a thorough check for leaks is performed. The initial startup is a critical moment. Ensure proper oil pressure builds quickly.

- Break-in and ECU Tuning: The engine must undergo a careful break-in period, typically involving varying RPMs and loads to seat the piston rings. After break-in, the most crucial step is custom ECU tuning on a dynamometer. This is where a skilled tuner optimizes fuel delivery, ignition timing, and other parameters specifically for your new engine configuration.

Based on my experience, rushing the assembly or skipping critical measurements like bearing clearances can lead to catastrophic engine failure. Precision and patience during the build process are non-negotiable. Always double-check torque specifications and use the correct lubricants.

Common Mistakes to Avoid When Building a Jeep Stroker

Embarking on a Jeep engine upgrade of this magnitude is exciting, but it’s also fraught with potential pitfalls. Avoiding these common mistakes will significantly increase your chances of a successful and reliable stroker build.

- Ignoring ECU Tuning: This is by far the biggest and most costly mistake. A stroker engine with stock ECU programming will run poorly, if at all, and is highly susceptible to detonation and premature failure. You absolutely must invest in custom tuning.

- Using Mismatched or Cheap Components: Trying to save a few dollars on critical parts like pistons, rods, or the camshaft can have disastrous consequences. An engine is an integrated system; components must be designed to work together harmoniously.

- Skipping Machine Shop Work: Assuming your block and crankshaft are "good enough" without professional inspection, boring, honing, and balancing is a recipe for disaster. These steps are fundamental for proper clearances, ring seating, and smooth operation.

- Not Upgrading Supporting Systems: A more powerful engine generates more heat and demands more fuel and airflow. Failing to upgrade your cooling system, fuel system, and exhaust system will choke your stroker’s potential and compromise its reliability.

- Rushing the Break-in Process: The initial break-in period allows piston rings to seat properly against the cylinder walls. Rushing this or subjecting the engine to high loads too soon can lead to poor ring seal, oil consumption, and reduced power.

- Lack of Cleanliness: Engine assembly requires an almost surgical level of cleanliness. Even small specks of dirt or debris can contaminate oil passages, score bearings, or cause other damage.

Pro tips from us: Always consult reputable forums like NAXJA or JeepForum for shared experiences and common pitfalls specific to the Jeep 4.0L stroker. Learn from others’ mistakes to ensure your build is a success.

Beyond the Engine: Supporting Modifications for Your Stroker Jeep

A Jeep 4.0 Stroker produces significantly more power and heat than a stock engine. To ensure reliability and extract maximum performance, you cannot neglect the supporting systems of your vehicle. Think of it like this: if you build a super-fast race car, you also need race-spec brakes and suspension.

- Cooling System: This is paramount. The increased heat generated by a larger, more powerful engine can quickly overwhelm a stock cooling system. Upgrade to a heavy-duty all-aluminum radiator, a high-flow water pump, and a robust fan clutch (or electric fan conversion). Regularly flush your cooling system and use quality coolant.

- Transmission: Your transmission will now be subjected to considerably more torque. If you have an automatic, consider a heavy-duty torque converter and potentially stronger internal components. Manual transmissions are generally more robust but might benefit from a heavy-duty clutch and flywheel.

- Drivetrain: The extra power will expose weak links in your drivetrain. Upgrading to stronger U-joints, reinforced driveshafts, and potentially more robust axle shafts (especially if running larger tires and aggressive off-roading) is a wise investment. Some might even consider a transfer case upgrade for increased strength or lower gearing.

- Brakes: With increased power and often heavier vehicle weight (due to accessories), your stopping power becomes even more critical. Upgrading to larger brake rotors, more potent calipers, and quality brake pads will significantly improve safety and confidence.

- Suspension: While not directly related to engine performance, a properly set up suspension is essential, especially if you’re running larger tires to complement your stroker. It ensures the power gets to the ground efficiently and safely, whether you’re rock crawling or cruising at highway speeds. For insights into selecting the right setup, you might find our Ultimate Guide to Jeep Suspension Lifts helpful.

These supporting modifications are not optional if you want a reliable and well-rounded performance vehicle. Ignoring them can lead to costly failures or, worse, dangerous situations.

Cost Considerations: Budgeting for Your Jeep Stroker Project

Building a Jeep Stroker Kit is an investment, both in time and money. The total cost can vary wildly depending on whether you do the work yourself, the quality of components chosen, and the extent of supporting modifications.

- DIY vs. Professional Build:

- DIY: You save significantly on labor costs, but you’ll need specialized tools (engine hoist, engine stand, torque wrenches, micrometers, bore gauges) and a significant amount of time. Parts and machine shop labor will be your primary expenses.

- Professional Build: A shop will handle everything, from engine removal to tuning. This convenience comes at a premium, with labor often matching or exceeding the cost of parts. Expect thousands in labor alone.

- Parts Cost: This is a broad spectrum.

- Budget Build (using junkyard 4.2L crank, refurbished rods, basic pistons): $1,500 – $3,000 for core engine parts.

- Mid-Range (new aftermarket crank, quality rods, custom pistons, mild head work, performance cam): $3,000 – $6,000.

- High-End (forged internals, ported aftermarket head, aggressive cam, premium fuel system): $6,000 – $10,000+.

- Machine Shop Labor: This is a significant, unavoidable cost. Expect to pay anywhere from $500 to $2,000+ for block cleaning, boring, honing, deck surfacing, crankshaft grinding, and balancing.

- Tuning Cost: Custom ECU tuning on a dynamometer will typically run $500 – $1,000, but it’s an absolutely non-negotiable expense.

- Hidden Costs: Don’t forget consumables like fluids, new hoses, belts, sensors, gaskets, and various bolts. You might also need new tools. Factor in a 10-20% contingency for unexpected issues.

Pro tips from us: Get detailed quotes from multiple machine shops and tuners. Create a comprehensive spreadsheet for all parts and labor. Understand that a quality stroker build is not cheap, but the performance payoff is immense. Don’t let budget constraints force you to cut corners on critical components or services.

Reliability and Longevity of a Stroker Engine

One of the most frequently asked questions about the Jeep 4.0 Stroker is about its reliability. The good news is that a properly built and maintained stroker engine can be just as reliable, if not more so, than a stock 4.0L. The myths about strokers being unreliable usually stem from poorly executed builds or inadequate supporting modifications.

The key to a long-lasting stroker lies in several critical factors:

- Quality Components: Using high-quality pistons, rods, bearings, and gaskets is fundamental. These components are designed to withstand the increased stresses of higher power output.

- Precision Machining and Assembly: Professional machine shop work ensures proper clearances, true surfaces, and balanced rotating assemblies. Meticulous assembly with correct torque specs and cleanliness prevents premature wear.

- Proper Tuning: This is paramount. An engine that runs too lean, too rich, or with incorrect timing will suffer damage quickly. A well-tuned stroker operates efficiently and safely within its design parameters.

- Adequate Cooling: As discussed, a robust cooling system is essential to manage the increased heat generated by a more powerful engine. Overheating is a swift killer of any engine, especially a modified one.

- Regular Maintenance: Just like any engine, a stroker needs consistent oil changes with quality oil, proper coolant levels, and regular inspections. Paying attention to unusual noises or performance changes can prevent minor issues from becoming major problems.

Based on my experience, many stroker engines have accumulated hundreds of thousands of miles without issue, performing flawlessly both on and off the trail. It truly comes down to the quality of the build and the care taken throughout the process. Don’t be afraid of the "stroker" label; embrace the potential for a powerful and reliable engine that will serve you well for years to come.

Is a Jeep 4.0 to 5.0 Stroker Kit Right for You?

So, after delving into the depths of the Jeep 4.0 Stroker, the ultimate question remains: is this significant Jeep engine upgrade the right choice for your vehicle and your needs?

A stroker kit is ideal for:

- Serious Off-Roaders: If you frequently tackle challenging trails, rock crawling, or mud bogging, the massive increase in low-end torque will be a game-changer. It provides the grunt needed to easily overcome obstacles and maintain control.

- Owners with Large Tires: Running 33-inch, 35-inch, or even larger tires significantly saps power from a stock 4.0L. A stroker restores and dramatically improves performance, making your Jeep feel nimble again.

- Performance Enthusiasts: If you simply crave more power, better acceleration, and a more responsive driving experience from your classic Jeep, a stroker delivers in spades.

- Those Planning a Rebuild Anyway: If your 4.0L is due for a rebuild, the added cost of stroker components and machining is often marginal compared to the significant performance gains.

However, it might not be for everyone. If you’re on a tight budget, rarely go off-road, or are happy with your stock performance, the investment might not be justified. Alternatives like forced induction (supercharger or turbocharger) offer different power characteristics, but often come with their own complexities and cost. Engine swaps are another option but are typically even more involved.

Ultimately, a Jeep 4.0 to 5.0 Stroker Kit transforms a reliable workhorse into a formidable powerhouse. It’s a project that demands commitment, research, and a willingness to invest, but the rewards are an incredibly capable, fun-to-drive, and truly unique Jeep that will turn heads and conquer any challenge you throw at it.

Conclusion: Embrace the Power of the Stroker

The Jeep 4.0L engine has earned its place in automotive history, revered for its simplicity and resilience. But for those who demand more, for those who push their Jeeps to the limits, the Jeep 4.0 to 5.0 Stroker Kit offers an unparalleled path to unlocking its true potential. This comprehensive Jeep engine upgrade isn’t just about bigger numbers on a dyno sheet; it’s about transforming your driving experience, making your Jeep more capable, more responsive, and undeniably more exciting.

From the meticulous selection of components like the crankshaft, connecting rods, and pistons, to the critical steps of block machining and custom ECU tuning, every detail contributes to a successful and reliable build. We’ve explored the profound benefits of increased torque for off-roading, enhanced drivability, and the sheer satisfaction of commanding a truly potent machine.

While it’s a significant undertaking requiring careful planning and a healthy budget, the investment in a well-executed stroker build pays dividends in performance and longevity. By avoiding common mistakes and dedicating yourself to quality, you can create a 4.0 Stroker that not only meets but far exceeds your expectations.

So, if you’re ready to elevate your Jeep’s performance to legendary status, consider the journey of the 4.0 to 5.0 stroker. It’s an adventure in itself, culminating in a driving experience that truly embodies the spirit of "Go Anywhere, Do Anything" with power to spare. Start planning your build today, and prepare to unleash the beast within your Jeep! For further reading on general engine maintenance to keep any Jeep running strong, check out our insights on Optimizing Your Jeep’s Performance with Regular Maintenance (internal link placeholder).