Unearthing the Cost: A Deep Dive into Concrete Price Per Yard in 2020 and What It Means for Your Project

Unearthing the Cost: A Deep Dive into Concrete Price Per Yard in 2020 and What It Means for Your Project Lmctruck.Guidemechanic.com

Embarking on any construction or home improvement project often involves a critical question: "What will this cost?" When it comes to concrete, a fundamental building material, the answer is rarely a simple figure. While we’re now well past 2020, understanding the dynamics of concrete pricing from that specific year offers invaluable insights into the industry’s mechanisms, supply chain sensitivities, and market influences that continue to shape costs today.

This comprehensive guide will take you on an in-depth journey through the world of concrete pricing in 2020, focusing specifically on the "price per yard." We’ll break down every factor, from the raw materials to the delivery logistics, providing you with a foundational understanding that will empower your budgeting and planning for any concrete endeavor, historical or contemporary. Our goal is to equip you with the knowledge to navigate concrete costs like a seasoned professional.

Unearthing the Cost: A Deep Dive into Concrete Price Per Yard in 2020 and What It Means for Your Project

What Exactly Is Concrete and Why Is Its Price So Variable?

Before we delve into specific pricing, let’s establish a common understanding. Concrete is a composite material made from a mixture of four key ingredients: cement, aggregates (like sand, gravel, or crushed stone), water, and sometimes chemical admixtures. When mixed, these components create a slurry that hardens over time, forming a durable, versatile construction material.

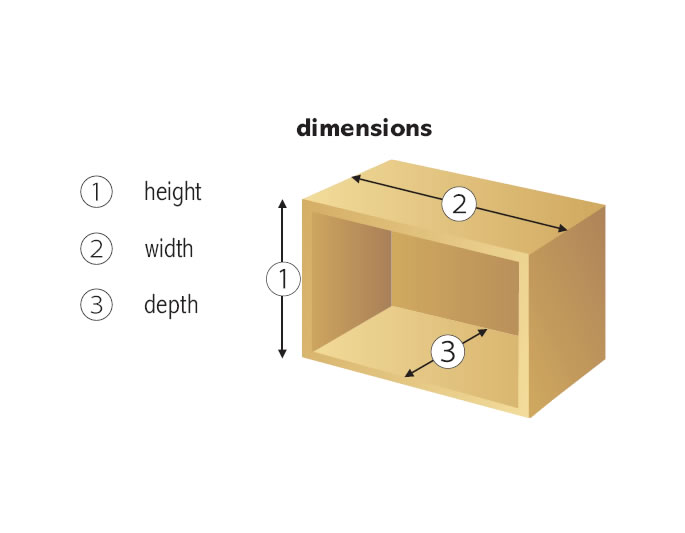

The standard unit of measurement for ordering concrete in North America is the cubic yard. One cubic yard is a volume roughly equivalent to 27 cubic feet (3 feet x 3 feet x 3 feet). This seemingly straightforward unit, however, hides a complex web of variables that cause the "price per yard" to fluctuate significantly.

Based on my extensive experience in the construction sector, the price variability of concrete is one of its most defining characteristics. It’s not like buying a standardized product off a shelf; each concrete order is, in many ways, custom-tailored to a project’s specific needs, location, and timeline. Understanding these nuances is crucial for accurate budgeting.

The Core Question: What Was the Average Concrete Price Per Yard in 2020?

In 2020, the average concrete price per cubic yard for ready-mix concrete typically ranged from $110 to $150. This figure generally included the cost of the material and standard delivery to a job site within a reasonable radius of the batch plant. However, it’s imperative to understand that this was merely an average, a starting point.

Pro tips from us: Never rely solely on an average. The actual cost for your specific project in 2020, or any year, could have been significantly higher or lower depending on a multitude of factors. Think of this range as a baseline from which we build our detailed understanding.

Deep Dive into Factors Influencing Concrete Price Per Yard (2020 Perspective)

To truly grasp the cost of concrete in 2020, we must dissect the myriad elements that contributed to its final price. Each factor played a role, sometimes subtle, sometimes profound, in shaping the quotes contractors and homeowners received.

1. Concrete Mix Design & Strength (PSI)

The strength of concrete is measured in pounds per square inch (PSI) and is a primary cost driver. Different applications require different strengths, and achieving higher PSI often demands more cement, specific aggregates, or specialized admixtures, all of which add to the cost.

For instance, a standard residential patio might only require a 2500 PSI mix, while a heavy-duty industrial floor or a structural foundation could demand 4000 PSI or even higher. The higher the PSI, the more expensive the mix generally becomes due to the increased proportion of cement and potentially higher quality aggregates.

In 2020, just as today, specifying the correct PSI was crucial not only for structural integrity but also for cost efficiency. Over-specifying strength meant unnecessary expenditure, while under-specifying could lead to structural failure and costly repairs.

2. Quantity Ordered: Economies of Scale and Short Load Fees

The total volume of concrete ordered has a substantial impact on the per-yard price. Concrete batch plants operate on economies of scale; they are set up to produce and deliver large quantities efficiently.

Larger orders, typically above 6-8 cubic yards, often result in a lower price per yard. This is because the fixed costs associated with dispatching a truck, driving to the site, and setting up for a pour are spread across more material. A 10-yard order would almost always yield a better per-yard rate than a 3-yard order.

Conversely, "short load fees" were a common surcharge in 2020 for orders below a certain minimum, often 4-6 cubic yards. These fees could add anywhere from $50 to $200 (or more) to the total bill, making small pours disproportionately expensive on a per-yard basis. It’s a mechanism for suppliers to cover their operational costs for smaller, less efficient deliveries.

3. Delivery Location & Distance from Batch Plant

Where your project is located in relation to the concrete batch plant significantly affects the price. Fuel costs, driver wages, and the wear and tear on trucks are all factored into delivery charges.

Most concrete suppliers in 2020 had a "free delivery zone," typically within 10-20 miles of their plant. Deliveries outside this radius incurred a mileage surcharge, which could be a flat fee per mile or a tiered system. Longer distances meant higher fuel consumption and more time spent on the road, directly translating to increased costs.

Common mistakes to avoid are not accurately assessing your site’s distance from potential suppliers. Always ask about their delivery zones and any applicable surcharges when requesting a quote. A slight difference in distance could significantly impact your overall concrete budget.

4. Time of Year & Demand Fluctuations

The construction industry is often cyclical, and concrete demand follows suit. In 2020, as in most years, peak construction seasons (typically spring, summer, and early fall in many regions) saw higher demand for concrete.

Increased demand can lead to slightly higher prices, less flexibility in delivery schedules, and potentially longer lead times. During off-peak seasons, when demand is lower, suppliers might offer more competitive pricing or have greater availability. Weather also plays a role; pouring concrete in extreme hot or cold weather requires special considerations (admixtures, curing blankets, heating/cooling water), which can add to the cost.

The year 2020, however, presented unique demand shifts. After an initial slowdown in the spring due to pandemic uncertainties, there was a significant surge in residential renovation and new home construction in the latter half of the year, which put upward pressure on prices in some regions.

5. Fuel Prices

Fuel is a substantial operating cost for concrete suppliers, impacting both the transportation of raw materials (aggregates, cement) to the batch plant and the delivery of the mixed concrete to the job site.

In 2020, global oil prices saw significant volatility. An initial collapse in the spring was followed by a gradual recovery. These fluctuations directly influenced the transportation component of concrete pricing. When fuel prices were higher, concrete delivery costs invariably increased.

Many suppliers include a "fuel surcharge" as a separate line item on invoices to account for these fluctuating costs. This ensures they can adapt their pricing without constantly re-issuing base rates.

6. Aggregate Costs (Sand, Gravel, Stone)

Aggregates make up the largest volume of concrete, typically 60-80% of the mix. Their cost is influenced by local availability, quarrying expenses, and transportation.

If quality sand and gravel are abundant near the batch plant, their cost will be lower. Conversely, if aggregates need to be hauled from a distant quarry, the transportation costs will be substantial, driving up the overall price of the concrete. The type and quality of aggregate also matter; specialized or high-performance aggregates are more expensive.

In 2020, local supply chain issues and quarry operational challenges, sometimes related to pandemic restrictions, could have impacted aggregate availability and pricing in specific regions.

7. Cement Prices

Cement is the "glue" that holds concrete together and is the most expensive single ingredient. Its price is influenced by manufacturing costs (which are energy-intensive), supply and demand dynamics, and global market conditions.

Cement production involves significant energy consumption, so energy prices directly impact cement costs. Any disruptions in cement production or transportation, such as those experienced globally during 2020, could lead to price increases and even supply shortages.

As the primary binding agent, changes in cement prices have a direct and significant ripple effect on the final cost per yard of concrete.

8. Labor Costs (for the Supplier)

The cost of operating a concrete batch plant includes labor for production, quality control, dispatch, and, crucially, the truck drivers. These labor costs are built into the per-yard price.

In 2020, like any other year, wages, benefits, and training for skilled personnel contributed to the overhead of concrete suppliers. While not typically a line item you see, it’s an inherent part of the material cost.

Beyond the Yard: Other Costs to Consider for Your Concrete Project (2020 Context)

Based on my years overseeing concrete projects, the material cost per yard is often just one piece of the puzzle. To accurately budget for any concrete job in 2020, or any year, you needed to consider several other essential expenses. Overlooking these can lead to significant budget overruns.

A. Site Preparation

Before any concrete can be poured, the site needs to be prepared. This typically involves:

- Excavation: Removing soil or existing structures to achieve the desired depth and grade.

- Grading: Leveling and shaping the ground to ensure proper drainage and slab thickness.

- Sub-base Material: Laying and compacting a layer of gravel or crushed stone to provide a stable, well-drained foundation for the concrete. This often includes material cost and compaction equipment rental or labor.

B. Reinforcement Materials

Concrete is strong in compression but weak in tension. Reinforcement helps it resist cracking and provides structural integrity. Common reinforcement materials include:

- Rebar (Reinforcing Bar): Steel bars used for heavy-duty applications like foundations and structural slabs.

- Wire Mesh: A grid of steel wires often used in slabs, driveways, and patios to control shrinkage cracking.

- Fibers: Synthetic or steel fibers mixed directly into the concrete to improve ductility and crack resistance.

The cost of these materials, along with the labor for placement, must be factored in.

C. Forms and Forming Materials

To give the concrete its desired shape, forms are constructed. These can be made from lumber, plywood, metal, or specialized plastic systems.

- Material Cost: For lumber, stakes, form release agents.

- Labor Cost: For skilled workers to accurately set, brace, and remove the forms. This is a critical step for achieving straight edges and correct dimensions.

D. Finishing and Curing

The surface finish of concrete can range from a basic broom finish to elaborate stamped patterns. Each finish has different labor and material requirements:

- Troweling/Floating: To achieve a smooth, dense surface.

- Broom Finish: For slip resistance on sidewalks and driveways.

- Stamping/Coloring: For decorative effects, which adds significant cost in terms of specialized tools, materials, and skilled labor.

- Sealing: Applying a sealer protects the concrete from stains and wear, adding to material and labor costs.

Proper curing is also essential for concrete strength and durability. This might involve curing compounds, wet curing, or covering the slab with blankets, all of which incur costs.

E. Concrete Pumping Services

For projects with difficult access, such as backyard patios behind a house or elevated slabs, a concrete pump becomes essential. This is a separate service and adds a significant cost.

- Pump Rental Fee: Often a minimum charge for the first few hours, plus an hourly rate thereafter.

- Line Fees: If extra long hoses are required.

Common mistakes to avoid are underestimating the cost and necessity of a concrete pump for difficult-to-reach areas. Always discuss access with your concrete supplier or contractor.

F. Labor for Installation (Placement and Finishing)

Unless you are doing the work yourself, you’ll need to account for the labor cost of the crew that places, levels, and finishes the concrete. This is distinct from the material cost per yard.

- Hourly Rates: For concrete finishers, laborers, and supervisors.

- Project-Based Quotes: Many contractors provide a lump sum for the entire installation.

The skill and experience of the concrete crew greatly impact the quality and longevity of the finished product.

How to Get an Accurate Concrete Quote (2020 & Beyond)

Getting a precise quote for concrete requires providing specific details to your supplier. Vague requests will only yield vague estimates. Based on my experience, here’s what you need to have ready:

- Exact Quantity (Cubic Yards): Calculate this precisely. Length x Width x Thickness (in feet) / 27 = Cubic Yards. Always add 5-10% for waste, uneven sub-grade, or spillage.

- Required PSI and Slump: Specify the desired strength and slump (a measure of consistency/workability).

- Admixtures: List any necessary admixtures (e.g., air-entrainment for freeze-thaw resistance, retarders for hot weather, accelerators for cold weather).

- Delivery Address: Provide the full address for accurate delivery cost calculation.

- Delivery Date and Time: Specify your preferred window.

- Access Information: Mention any access challenges (e.g., tight turns, steep driveways, need for a pump).

- Payment Terms: Clarify payment requirements (e.g., deposit, payment upon delivery).

Pro tips from us: Always get at least three quotes from different ready-mix suppliers. This allows you to compare prices, delivery terms, and customer service. Don’t just go for the cheapest option; reliability and quality are paramount in concrete work.

The Unique Impact of 2020 on Concrete Pricing

The year 2020 was unprecedented, and its global events inevitably rippled through the construction industry, affecting concrete prices and availability.

Initially, in the spring of 2020, many construction projects were paused or delayed due to economic uncertainty and public health measures. This led to a temporary dip in demand and potentially more competitive pricing from suppliers eager to maintain sales.

However, as the year progressed, a significant shift occurred. A surge in home renovation projects and new residential construction, fueled by low interest rates and a desire for improved living spaces during lockdowns, created a strong rebound in demand. This surge, combined with supply chain disruptions, labor shortages (due to health concerns or restrictions), and volatile fuel prices, put upward pressure on concrete costs in many regions.

Ready-mix plants had to adapt to new safety protocols, which sometimes affected efficiency. Transportation networks faced challenges, impacting the timely delivery of raw materials and finished concrete. These unique stressors of 2020 highlighted the interconnectedness of global events and local construction costs.

Is DIY Concrete a Cost-Saving Option? (2020 Perspective)

Many homeowners in 2020, looking to save money during uncertain economic times, considered tackling concrete projects themselves. While DIY can reduce labor costs, it’s crucial to understand the trade-offs.

For very small projects, like a stepping stone or a small repair, mixing bags of concrete by hand can be cost-effective. However, for anything larger – a patio, a driveway, or a slab – the cost savings of DIY concrete can quickly evaporate, and the risks increase significantly.

Common mistakes to avoid are underestimating the physical demands and technical skill required for a professional-looking concrete finish. Pouring concrete is time-sensitive; once the truck arrives, you have a limited window to place, level, and finish the material correctly. Without proper tools, experience, and enough helping hands, mistakes are common and costly to rectify. The cost of renting specialized equipment (vibrators, power trowels), buying forms, and the potential for expensive errors often outweigh the perceived savings.

Future Outlook & Timeless Principles (Beyond 2020)

While our focus has been on concrete price per yard in 2020, the principles discussed are timeless. The fundamental factors influencing concrete costs – mix design, quantity, location, fuel, raw material prices, and labor – remain constant. Economic shifts, supply chain resilience, and market demand will always play a role.

Moving forward, understanding these variables will continue to be essential for accurate project budgeting. While average prices will naturally evolve with inflation and market dynamics, the mechanisms behind those prices will largely stay the same. Savvy planning, detailed specifications, and seeking multiple quotes will always be your best tools for managing concrete costs effectively.

For more in-depth information on specific concrete applications, you might find our article on helpful. And for understanding the broader economic factors that influence construction material costs, you can always refer to reputable sources like the for historical fuel price data.

Conclusion: Mastering Your Concrete Budget

The "Concrete Price Per Yard 2020" wasn’t a static number; it was a dynamic reflection of material science, market forces, logistical challenges, and even global events. By dissecting these components, we gain a clearer picture of not just what concrete cost in 2020, but why.

Understanding these influencing factors is the cornerstone of effective project planning and budgeting for any concrete endeavor. Whether you’re a homeowner planning a small project or a contractor managing a large-scale development, knowing the intricacies of concrete pricing empowers you to make informed decisions, negotiate effectively, and ensure your project stays on budget and on track. Always plan wisely, gather comprehensive information, and don’t hesitate to seek expert advice. Your concrete project’s success hinges on a solid understanding of its true cost.