The Unseen Guardians: A Deep Dive into Supreme Truck Body Door Parts and Why They Are Crucial for Your Fleet

The Unseen Guardians: A Deep Dive into Supreme Truck Body Door Parts and Why They Are Crucial for Your Fleet Lmctruck.Guidemechanic.com

In the demanding world of commercial transportation, every component of a truck plays a vital role in its overall efficiency, safety, and profitability. While engines, tires, and chassis often grab the spotlight, the humble truck body door and its intricate parts are the unsung heroes. They are the frontline defense for your valuable cargo, the gatekeepers of your operational flow, and a significant factor in your fleet’s professional image.

For fleet managers and owner-operators who prioritize durability, security, and seamless operation, understanding Supreme Truck Body Door Parts is not just an advantage—it’s a necessity. This comprehensive guide will explore the critical importance of these components, deconstruct their various types, and provide expert insights into their selection, maintenance, and impact on your bottom line. Get ready to unlock the secrets to a more secure, efficient, and long-lasting fleet.

The Unseen Guardians: A Deep Dive into Supreme Truck Body Door Parts and Why They Are Crucial for Your Fleet

Why Supreme Truck Body Door Parts Matter: The Unsung Heroes of Logistics

The doors on your commercial truck bodies are far more than simple access points. They are complex systems designed to withstand constant use, harsh weather, and the rigors of daily deliveries. The quality and condition of each individual part directly influence the door’s performance and, by extension, your entire operation.

Investing in Supreme Truck Body Door Parts means opting for components that meet the highest standards of manufacturing and durability. These parts are engineered to perform flawlessly, offering superior protection and longevity compared to lesser alternatives. This choice reflects a commitment to operational excellence and cargo security.

Here’s why these components are absolutely critical:

- Safety and Security of Cargo: The primary function of a truck door is to secure its contents. High-quality latches, locks, and hinges prevent theft and ensure cargo remains intact during transit. Any compromise in these parts can lead to costly losses and damaged goods.

- Operational Efficiency and Driver Productivity: A door that sticks, rattles, or fails to close properly causes delays, frustration, and lost time. Smoothly operating doors allow drivers to perform their duties quickly and efficiently, keeping schedules on track. Based on my experience, even a few minutes lost per stop due to a faulty door can add up to significant downtime over a week.

- Protection from the Elements: Weather seals, door panels, and frames are designed to keep rain, snow, dust, and extreme temperatures out. Intact seals are crucial for protecting sensitive cargo, preventing water damage, and maintaining internal temperature control, especially for refrigerated units.

- Compliance and Regulations: Many industries have strict regulations regarding cargo securement and vehicle safety. Maintaining doors with high-quality, functioning parts helps ensure your fleet remains compliant, avoiding potential fines and legal issues. It’s not just about preference; it’s often about legal obligation.

- Longevity and Resale Value of the Vehicle: Well-maintained doors with durable parts contribute to the overall structural integrity of the truck body. This not only extends the operational lifespan of the vehicle but also significantly enhances its resale value. Potential buyers will always scrutinize the condition of doors and their hardware.

Deconstructing the Door: Essential Supreme Truck Body Door Parts

Truck body doors come in various configurations, primarily roll-up (overhead) and swing (barn) door styles. Each style relies on a specific set of robust components to function effectively. Understanding these distinct truck body door components is key to proper maintenance and replacement.

Roll-Up Door Components: The Overhead Advantage

Roll-up doors, common on dry freight and refrigerated trucks, offer convenience in tight spaces. Their intricate design requires a specific set of highly durable roll-up door parts.

- Tracks and Rollers: These form the backbone of the roll-up mechanism. Heavy-duty steel tracks guide the door panels, while sealed-bearing rollers ensure smooth, quiet operation. Wear on these parts can lead to grinding noises and sticking doors.

- Spring Assemblies: The counterbalance system, typically involving torsion springs or extension springs, is crucial for lifting and lowering the door with ease. These springs bear significant tension and are critical safety components. A broken spring can make the door extremely heavy and dangerous to operate.

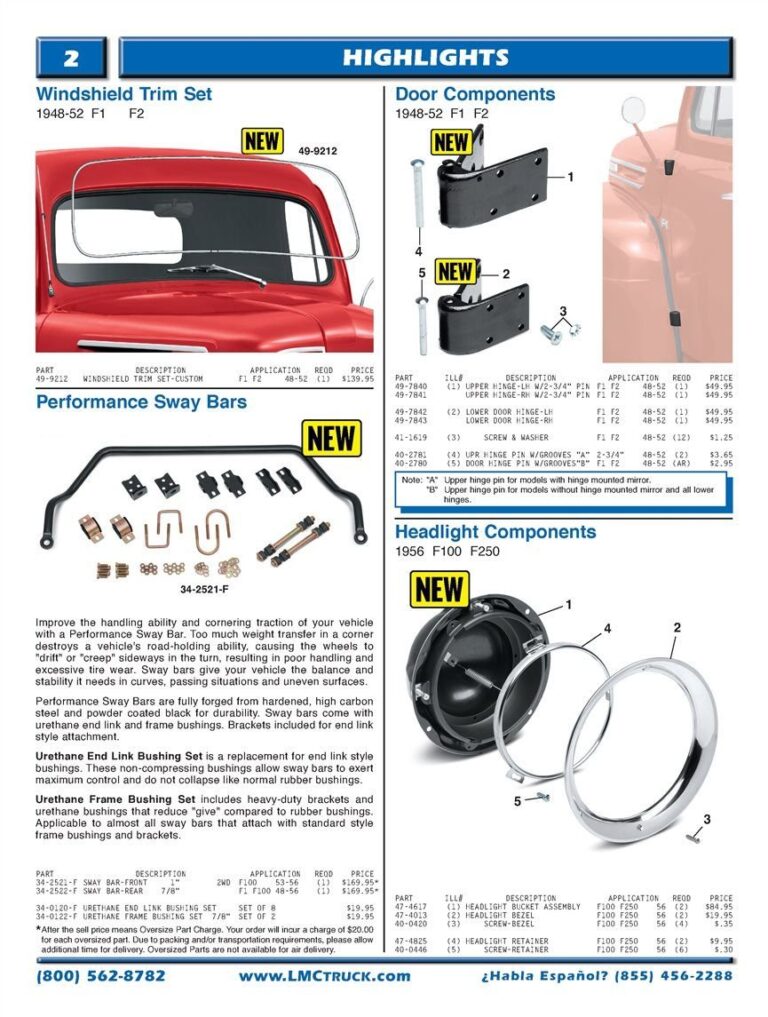

- Hinges and Handles: Hinges connect the individual door panels, allowing them to articulate as the door rolls up. Durable handles, often with integrated locking mechanisms, provide secure access and ease of operation. Commercial truck door hardware must withstand constant impact and heavy use.

- Door Panels/Slats: These are the primary protective barrier, typically made from aluminum, steel, or composite materials. They interlock to form a rigid, secure door. Damage to individual slats can compromise the entire door’s integrity and weatherproofing.

- Weather Seals: Located along the sides and bottom of the door, these seals prevent moisture and air intrusion. High-quality seals, often made of robust rubber or vinyl, are essential for cargo protection and temperature control. Checking them regularly is a pro tip from us.

Swing Door Components: The Classic Workhorses

Swing doors, often seen on box trucks and trailers, are known for their simplicity and robustness. Their cargo door replacement parts are generally simpler but no less critical.

- Heavy-Duty Hinges: Unlike roll-up door hinges, swing door hinges bear the full weight of the door. They must be exceptionally strong, often made of forged steel or high-grade aluminum, to prevent sagging and misalignment. Proper lubrication and regular inspection are vital for these parts.

- Latches and Locks: These are the primary security mechanisms for swing doors. Robust cam-style latches, often paired with secure padlock hasps, ensure the doors remain firmly closed during transit. Durable truck door hardware in this area is paramount for security.

- Door Seals/Gaskets: Similar to roll-up doors, swing doors require effective seals around the perimeter to prevent water and dust ingress. These are often rubber or vinyl gaskets designed to compress tightly when the door is closed. Common mistakes to avoid are neglecting cracked or hardened seals.

- Door Holdbacks: These simple yet effective devices secure the doors in an open position, preventing them from swinging shut unexpectedly during loading or unloading. They enhance safety and efficiency in busy environments.

- Door Frames: The structural integrity of the door frame, often steel or aluminum, is essential. Damage to the frame can compromise the entire door’s alignment and sealing capabilities.

Choosing the Right Supreme Truck Body Door Parts: A Strategic Decision

Selecting the correct parts for Supreme truck bodies isn’t just about finding a replacement; it’s about making a strategic decision that impacts safety, efficiency, and long-term costs. The market offers a range of options, from Original Equipment Manufacturer (OEM) parts to various aftermarket alternatives.

Here’s how to make an informed choice:

- Compatibility and Fitment: Always ensure the part is specifically designed for your truck body’s make, model, and door type. Generic parts might seem cheaper initially but can lead to poor fitment, accelerated wear, and operational issues. Always verify part numbers.

- Material Quality and Construction: Examine the materials used. Is it high-grade steel, robust aluminum, or durable composite? Inferior materials will corrode faster, bend under stress, or simply wear out prematurely. Look for evidence of quality manufacturing, such as proper welding, durable coatings, and strong fasteners.

- Durability Ratings and Testing: Reputable manufacturers will often provide durability ratings or information on how their parts are tested. This can give you confidence in the part’s ability to withstand the demanding conditions of commercial use. Based on my experience, investing in parts with proven longevity saves money in the long run.

- Supplier Reputation and Warranty: Purchase from trusted suppliers known for quality commercial truck door hardware. A strong warranty indicates the manufacturer stands behind their product. A reliable supplier can also offer expert advice and support.

- Budget vs. Long-Term Value: While budget is always a consideration, opting for the cheapest option often proves more expensive due to frequent replacements and increased downtime. Prioritize long-term value, which factors in durability, performance, and reduced maintenance. Pro tips from us: view quality parts as an investment, not an expense.

Installation and Maintenance: Extending the Lifespan of Your Truck Doors

Even the highest quality Supreme Truck Body Door Parts will underperform or fail prematurely without proper installation and diligent maintenance. This section focuses on best practices to ensure your doors remain in peak condition.

Professional Installation: A Non-Negotiable Step

While some minor repairs might be DIY-friendly, critical components like spring assemblies, tracks, and heavy-duty hinges should always be installed by trained professionals.

- Precision is Key: Proper alignment, tensioning, and securing of parts are crucial for optimal function and safety. Incorrect installation can lead to immediate operational problems or hidden stresses that cause premature failure.

- Safety Considerations: Components like torsion springs are under extreme tension and can cause serious injury if not handled correctly. Professional installers have the right tools and expertise to manage these risks.

- Warranty Compliance: Many manufacturers require professional installation for warranty validity. Attempting a DIY installation on complex parts might void your coverage.

Regular Maintenance: The Backbone of Durability

A proactive approach to truck door maintenance can significantly extend the life of your door parts and prevent costly breakdowns.

- Regular Inspections: Implement a routine schedule for inspecting all door components. Look for signs of wear, corrosion, cracks, loose fasteners, or damage. Pay close attention to hinges, rollers, tracks, latches, and weather seals. Early detection of issues can save major repair costs.

- Lubrication: Moving parts, especially hinges, rollers, and lock mechanisms, require regular lubrication with appropriate lubricants (e.g., silicone spray for seals, white lithium grease for metal-on-metal). This reduces friction, prevents rust, and ensures smooth operation.

- Cleaning: Keep tracks, rollers, and seals free from dirt, grime, and debris. Accumulations can impede movement and cause premature wear. A simple cleaning with mild soap and water can make a big difference.

- Adjustments: Over time, doors can go out of alignment or spring tension can decrease. Regular adjustments by a professional can correct these issues, restoring optimal performance.

Common mistakes to avoid are: neglecting minor issues, using inappropriate lubricants, or forcing a stiff door. These actions can quickly escalate small problems into major repairs. For more in-depth fleet maintenance strategies, you can learn more about fleet maintenance strategies here (Internal Link 1).

Troubleshooting Common Issues with Supreme Truck Body Doors

Even with the best parts and maintenance, issues can arise. Knowing how to identify and address common problems with your secure truck cargo doors can minimize downtime.

- Sticking or Jamming Doors:

- Cause: Dirt in tracks, worn rollers, bent tracks, or misaligned door panels (especially for roll-up doors). For swing doors, it could be binding hinges or a warped door.

- Solution: Clean and lubricate tracks and rollers. Inspect for bent or damaged components and replace as needed. Check door alignment.

- Loose or Worn Hinges:

- Cause: Frequent heavy use, insufficient lubrication, or loose fasteners.

- Solution: Tighten fasteners. If hinges are excessively worn, they need replacement to prevent door sagging or complete failure. Ensure regular lubrication.

- Damaged Weather Seals:

- Cause: Age, exposure to elements, friction, or impact damage.

- Solution: Replace damaged or cracked seals immediately. This is crucial for cargo protection and energy efficiency.

- Broken Latches or Locks:

- Cause: Forced entry, impact, or normal wear and tear.

- Solution: Replace broken latches and locks with high-quality, durable components. Never compromise on security.

- Excessive Noise (Squeaking, Grinding):

- Cause: Lack of lubrication, worn rollers, bent tracks, or loose hardware.

- Solution: Lubricate all moving parts. Inspect for worn components and replace them. Check and tighten all fasteners.

The Impact of Quality Door Parts on Your Business Bottom Line

The true cost of a cheap door part isn’t just its purchase price; it’s the ripple effect it has on your entire operation. Conversely, investing in durable truck door hardware provides significant returns.

- Reduced Downtime: Reliable doors mean fewer unexpected breakdowns and less time spent on repairs. This directly translates to more time on the road, making deliveries, and generating revenue. Every minute a truck is off the road is a minute of lost income.

- Improved Security and Reduced Loss: High-quality locks and latches deter theft, protecting valuable cargo and preventing costly insurance claims. Secure doors provide peace of mind for both the fleet owner and the client.

- Enhanced Professional Image: A fleet with well-maintained, fully functional doors projects professionalism and reliability. This positively impacts customer perception and can lead to repeat business and new contracts. Your trucks are moving billboards; what message do they convey?

- Compliance and Safety Records: Properly functioning doors contribute to a safer working environment for drivers and loaders, reducing the risk of accidents and injuries. This can lead to lower insurance premiums and better safety ratings. The Federal Motor Carrier Safety Administration (FMCSA) emphasizes vehicle maintenance for safety; you can find more information on their guidelines here. (External Link 1)

Pro Tips from an Industry Veteran: Maximizing Your Investment

Having spent years navigating the complexities of fleet management, I’ve gathered some invaluable insights regarding fleet maintenance tips and truck body door parts.

- Always Prioritize Quality Over Cost: This might sound cliché, but it’s especially true for high-wear items like door parts. The initial savings from a cheap part are almost always negated by increased repair frequency, labor costs, and operational disruptions. Choose OEM or high-quality aftermarket parts with a proven track record.

- Establish a Robust Preventative Maintenance Schedule: Don’t wait for a door to break before addressing it. Implement a schedule for regular inspections, cleaning, and lubrication. This proactive approach catches minor issues before they become major problems.

- Train Your Drivers on Proper Door Operation: Many door issues stem from improper use or slamming. Educate drivers on the correct way to open, close, and secure doors. This small effort can significantly reduce wear and tear.

- Keep a Small Inventory of Common Wear Parts: For critical components like rollers, certain seals, or common latch parts, having a small stock on hand can drastically reduce repair time. This is particularly useful for larger fleets.

- Develop a Relationship with a Trusted Parts Supplier: A good supplier can offer expert advice, help you source specific parts efficiently, and provide insights into the latest durable truck door hardware innovations. They are an extension of your maintenance team. For a deeper dive into choosing commercial vehicle accessories, consider reading our guide on selecting the right accessories for your commercial vehicles (Internal Link 2).

Conclusion: Elevating Your Fleet with Superior Door Parts

The doors on your commercial truck bodies are more than just entryways; they are critical components that safeguard your assets, ensure operational continuity, and reflect your commitment to quality. By understanding the intricate world of Supreme Truck Body Door Parts, from their diverse types to their crucial role in security and efficiency, you empower yourself to make informed decisions.

Investing in high-quality parts, coupled with diligent installation and proactive maintenance, is not merely an expense—it’s a strategic investment in the longevity of your fleet, the safety of your cargo, and the profitability of your business. Don’t underestimate these unseen guardians; give them the attention they deserve, and they will serve your fleet faithfully for miles to come. Prioritize these vital components, and watch your fleet operate with unparalleled reliability and peace of mind.