The Ultimate Guide to the Parts of a Truck: Unveiling the Anatomy of Your Workhorse

The Ultimate Guide to the Parts of a Truck: Unveiling the Anatomy of Your Workhorse Lmctruck.Guidemechanic.com

Trucks are more than just vehicles; they are indispensable tools, loyal companions, and the backbone of countless industries. From hauling heavy loads on construction sites to navigating challenging terrains for adventure, or simply making daily commutes, trucks perform a remarkable array of tasks. But what exactly makes these robust machines tick?

Understanding the intricate parts of a truck isn’t just for mechanics; it’s vital for every truck owner, operator, or enthusiast. Knowing the fundamental components can empower you to make informed decisions about maintenance, troubleshoot minor issues, enhance safety, and even save significant money in the long run. This comprehensive guide will strip down the truck, layer by layer, revealing its essential anatomy and explaining the function of each critical component. Get ready to dive deep into the fascinating world of truck mechanics!

The Ultimate Guide to the Parts of a Truck: Unveiling the Anatomy of Your Workhorse

Why Understanding Your Truck’s Anatomy Matters

Before we dissect the truck, let’s explore why this knowledge is so crucial. Based on my extensive experience working with various truck models and advising owners, a foundational understanding of truck parts translates directly into practical benefits. It’s not about becoming a certified mechanic overnight, but rather about becoming a more informed and proactive truck owner.

Firstly, safety is paramount. Recognizing the signs of wear or malfunction in critical components like brakes, tires, or steering can prevent catastrophic failures on the road. Secondly, it empowers you to speak intelligently with mechanics, ensuring you understand repairs and aren’t overcharged for unnecessary work. Thirdly, proactive maintenance becomes second nature when you know what to look for, extending your truck’s lifespan and maintaining its resale value. Finally, it builds a deeper appreciation for the engineering marvel that is your truck.

The Foundation: Chassis and Frame

Every building needs a strong foundation, and a truck is no different. The chassis and frame form the skeletal structure that supports all other components and withstands the immense forces generated during operation. Without a robust frame, a truck simply wouldn’t exist as we know it.

The frame is typically a ladder-like structure made of high-strength steel beams, running the length of the vehicle. These beams are cross-braced for rigidity, providing the mounting points for the engine, transmission, suspension, axles, and body. Its primary role is to provide structural integrity, distribute weight evenly, and absorb road shocks. The chassis encompasses the frame along with the engine, drivetrain, suspension, and steering systems – essentially everything but the body.

For heavy-duty trucks, the frame’s strength is absolutely critical, as it must support massive payloads. Lighter-duty trucks might use a combination of body-on-frame or even unibody construction (where the body and frame are integrated) for improved ride comfort and fuel efficiency, though pure unibody is rare in traditional trucks. Pro tips from our team: Always inspect the frame for rust, cracks, or damage, especially if you’re buying a used truck, as frame integrity is non-negotiable for safety and performance.

The Heartbeat: The Engine

The engine is undeniably the heart of any truck, generating the power required to move massive weights and conquer challenging terrains. Most trucks today utilize internal combustion engines, primarily running on either gasoline or diesel fuel. Each type has its advantages, with diesel engines often favored for their torque, fuel efficiency, and longevity in heavy-duty applications.

Let’s break down the core components within the engine:

- Engine Block: The main casting that houses the cylinders and provides a framework for other components.

- Cylinders and Pistons: Within each cylinder, a piston moves up and down, compressing the fuel-air mixture and transferring power from the combustion.

- Crankshaft: This large shaft converts the linear motion of the pistons into rotational motion, which is then sent to the drivetrain.

- Camshaft: Controls the opening and closing of the intake and exhaust valves, precisely timing the engine’s breathing.

- Valves: Regulate the flow of air and fuel into the combustion chamber and exhaust gases out of it.

- Fuel System: Includes the fuel tank, pump, lines, and injectors, delivering fuel to the engine.

- Exhaust System: Comprises the exhaust manifold, catalytic converter, and muffler, channeling spent gases away from the engine and reducing emissions and noise.

- Cooling System: Made up of the radiator, water pump, hoses, and thermostat, this system prevents the engine from overheating, which is crucial for engine longevity.

Understanding these engine parts is key to recognizing potential issues. For instance, unusual smoke from the exhaust could indicate a fuel system problem, while an overheating engine points to cooling system trouble. for a deeper dive into the differences between these powerful hearts.

Putting Power to the Wheels: The Drivetrain

Once the engine creates power, the drivetrain is responsible for transmitting that power efficiently to the wheels. This complex system ensures your truck moves forward (or backward) with the right amount of force for any given situation, whether you’re cruising on the highway or crawling over rocks.

Key components of the drivetrain include:

- Transmission: This is a crucial component that allows the driver to select different gear ratios. In a manual transmission, the driver manually shifts gears using a clutch and gear stick. An automatic transmission handles gear changes automatically. The transmission multiplies engine torque at lower speeds for acceleration and reduces it at higher speeds for fuel efficiency.

- Clutch (for manual transmissions): A critical part that temporarily disconnects the engine from the transmission, allowing for smooth gear changes without grinding.

- Driveshaft (or Propeller Shaft): A rotating shaft that transmits power from the transmission to the differential, typically found in rear-wheel-drive and four-wheel-drive vehicles.

- Differential: Located between the drive wheels, the differential allows the wheels to rotate at different speeds when turning corners, preventing tire drag and ensuring smooth handling.

- Axles: These shafts connect the differential to the wheels, directly transmitting the rotational power. Trucks usually have a front axle and a rear axle, with some heavy-duty models featuring multiple rear axles.

- Transfer Case (for 4×4 trucks): In four-wheel-drive trucks, the transfer case allows the driver to switch between two-wheel drive and four-wheel drive, distributing power to both front and rear axles as needed.

Common mistakes to avoid regarding the drivetrain include neglecting transmission fluid changes, ignoring warning signs like grinding noises or difficulty shifting, and improper use of 4×4 systems. Regular fluid checks and timely service are vital for these hardworking components.

Smooth Rides and Heavy Loads: Suspension and Steering

The suspension and steering systems work in concert to provide a comfortable ride, maintain tire contact with the road, and allow the driver to control the truck’s direction. These are especially critical in trucks, which often carry heavy loads and traverse varied terrain.

The suspension system absorbs shocks and bumps from the road, keeping the tires firmly on the ground for optimal traction. Its main components include:

- Springs: These absorb and store energy from road imperfections. Common types in trucks include leaf springs (multiple bowed metal strips, common in rear suspensions for heavy loads), coil springs (helical-shaped springs, often found in front suspensions for smoother rides), and air springs (airbags that can adjust ride height and stiffness, prevalent in heavy-duty trucks).

- Shock Absorbers (or Dampers): These dampen the oscillations of the springs, preventing the truck from bouncing excessively after hitting a bump. They convert kinetic energy into heat, dissipating it.

- Control Arms (or Wishbones): These connect the wheel hub to the chassis, allowing the wheel to move up and down while maintaining proper alignment.

- Sway Bars (or Anti-roll Bars): These reduce body roll during cornering, improving stability.

The steering system translates the driver’s input from the steering wheel into directional changes of the front wheels. Key parts include:

- Steering Wheel and Steering Column: The interface for the driver and the shaft connecting it to the steering gear.

- Steering Gear: This mechanism converts the rotational motion of the steering column into linear motion to move the tie rods. Common types in trucks are rack-and-pinion (more precise, common in lighter trucks) and recirculating ball (more robust, common in heavy-duty trucks).

- Tie Rods: These connect the steering gear to the steering knuckles, which turn the wheels.

- Power Steering Pump: Most modern trucks have power steering, which uses hydraulic pressure (or electric assistance) to reduce the effort required to turn the steering wheel.

A properly functioning suspension and steering system are paramount for safe handling, stability, and driver comfort. Any unusual noises, excessive bouncing, or loose steering should be investigated immediately.

Stopping Power: The Braking System

No matter how powerful a truck is, its ability to stop safely and efficiently is arguably its most critical safety feature. The braking system is designed to slow down or halt the vehicle by converting kinetic energy into heat through friction. Given the weight and momentum of trucks, robust brakes are absolutely essential.

The core components of a modern truck’s braking system include:

- Brake Pedal: The driver’s input point, connected to the master cylinder.

- Master Cylinder: This converts the force from the brake pedal into hydraulic pressure, pushing brake fluid through the lines.

- Brake Lines: Steel or rubber hoses that carry the hydraulic brake fluid to each wheel.

- Brake Calipers (for disc brakes): These assemblies house the brake pads and hydraulic pistons. When pressure is applied, the pistons push the pads against the rotor.

- Brake Pads: Friction material that presses against the brake rotor.

- Brake Rotors (or Discs): Large metal discs attached to the wheel hub that the brake pads clamp onto.

- Brake Drums (for drum brakes): Cylindrical components that rotate with the wheel. Inside the drum, brake shoes press outwards against the drum’s inner surface to create friction.

- Anti-lock Braking System (ABS): A crucial safety feature that prevents the wheels from locking up during hard braking, allowing the driver to maintain steering control. It uses sensors to monitor wheel speed and modulate brake pressure.

Regular inspection of brake pads, rotors, fluid levels, and brake lines is non-negotiable. Our deep understanding of truck mechanics reveals that neglecting brake maintenance is one of the most dangerous oversights truck owners can make. Always address squealing, grinding, or a spongy brake pedal promptly.

Bringing it to Life: The Electrical System

In today’s trucks, the electrical system is far more than just a way to start the engine. It’s a complex network that powers everything from the engine’s ignition and fuel injection to the infotainment system, safety features, and countless sensors. Without a healthy electrical system, your truck simply wouldn’t function.

Key components of the electrical system include:

- Battery: Stores electrical energy, providing the initial power to start the engine and supplying power to accessories when the engine is off.

- Alternator: Once the engine is running, the alternator generates electricity to power the truck’s electrical systems and recharge the battery.

- Starter Motor: A powerful electric motor that turns the engine’s crankshaft to initiate combustion.

- Wiring Harness: A complex bundle of wires, connectors, and fuses that distribute electrical power and signals throughout the entire truck.

- Lights: Headlights, tail lights, turn signals, brake lights, interior lights – all essential for visibility and communication.

- Sensors and Electronic Control Units (ECUs): Modern trucks are laden with sensors that monitor everything from engine temperature and oxygen levels to wheel speed and cabin temperature. These sensors feed data to various ECUs (like the Engine Control Unit, Transmission Control Unit, etc.), which then make real-time adjustments for optimal performance, efficiency, and safety.

Troubleshooting electrical issues can be challenging due to their interconnected nature, but understanding the basics can help. A dim headlight or a failing accessory could indicate a weak battery, a faulty alternator, or a blown fuse.

The Driver’s Command Center: The Cabin and Interior

While the mechanical parts ensure the truck moves and functions, the cabin is where the human element interacts with the machine. It’s the driver’s command center, designed for control, comfort, and safety. The interior design of a truck has evolved significantly, balancing rugged utility with increasingly sophisticated features.

Inside the cabin, you’ll find:

- Dashboard: Houses the instrument cluster (speedometer, tachometer, fuel gauge, temperature gauge) and various warning lights.

- Steering Wheel: The primary control for directional input.

- Seats: Designed for comfort and support, especially on long drives, with many trucks offering adjustable lumbar support and heating/cooling.

- Pedals: Accelerator, brake, and clutch (for manual transmissions).

- Infotainment System: Modern trucks often feature large touchscreens with navigation, audio controls, smartphone integration, and connectivity options.

- HVAC System: Heating, Ventilation, and Air Conditioning for climate control.

- Safety Features: Airbags, seatbelts, and increasingly, advanced driver-assistance systems (ADAS) like lane-keeping assist, adaptive cruise control, and blind-spot monitoring.

The cabin is where the driver receives critical information and makes decisions, making its layout and functionality key to a safe and enjoyable driving experience.

The Outer Shell: Body Components

Beyond the interior, the body components form the visible exterior of the truck, contributing to its aerodynamics, protection, and overall aesthetic. These parts are often subjected to the elements and potential impacts, so their design and materials are important.

Key body parts include:

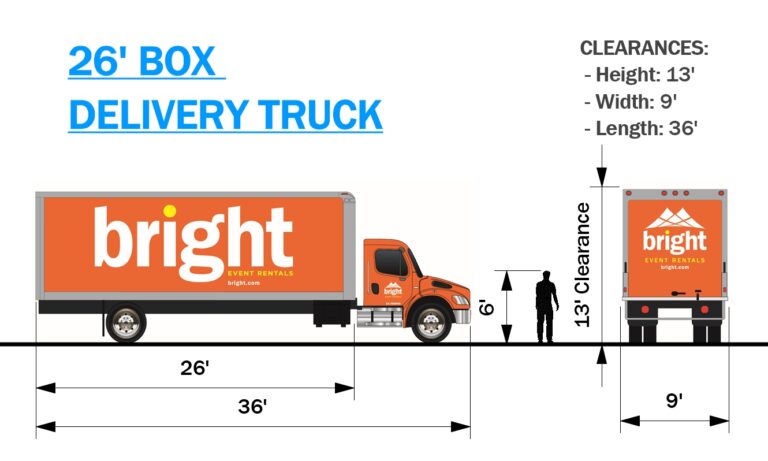

- Cab: The enclosed section where the driver and passengers sit. Cabs come in various configurations (single cab, extended cab, crew cab) to accommodate different passenger capacities.

- Hood (or Bonnet): The hinged cover over the engine compartment, providing access for maintenance.

- Fenders: Panels that arch over the wheels, protecting the engine and passenger compartment from dirt and debris thrown by the tires.

- Doors: Provide entry and exit to the cabin.

- Grille: The front opening that allows air to flow into the radiator for cooling, often a distinctive styling element.

- Bumpers: Located at the front and rear, designed to absorb impact in low-speed collisions and protect the chassis.

- Truck Bed (for pickup trucks): The open cargo area at the rear, designed for hauling goods. It can be fitted with various accessories like tonneau covers, bed liners, and toolboxes.

- Tailgate: The hinged door at the rear of the truck bed, allowing for easy loading and unloading.

- Trailer Hitch: A robust attachment point at the rear, used for towing trailers.

These body components not only give the truck its characteristic look but also play functional roles in protection and utility.

Wheels and Tires: The Contact Point

Finally, the wheels and tires are the only parts of the truck that actually touch the road, making them absolutely critical for traction, handling, braking, and carrying the vehicle’s weight. Their condition directly impacts safety and performance.

- Wheels (or Rims): These are the metal structures that the tires are mounted on. They come in various sizes and materials (steel, aluminum alloy) and must be strong enough to support the truck’s weight and withstand road forces.

- Tires: Inflatable rubber rings that provide the necessary grip on the road. Tires come in many types, each designed for specific conditions (all-season, all-terrain, mud-terrain, highway). Key aspects include:

- Tread: The patterned grooves on the tire’s surface, designed to provide traction and channel water away.

- Sidewall: The side of the tire, containing important information like size, load rating, and speed rating.

- Air Pressure: Crucial for tire performance, fuel efficiency, and safety. Incorrect tire pressure can lead to uneven wear, blowouts, and poor handling.

- Lug Nuts: Fasteners that secure the wheel to the wheel hub.

Pro tips from us: Always ensure your tires are properly inflated according to the manufacturer’s specifications. Regularly check tire tread depth and rotate your tires to ensure even wear. This simple habit can significantly extend tire life and improve safety.

Proactive Maintenance: Keeping Your Truck Running Strong

Now that you’ve journeyed through the intricate parts of a truck, it becomes clear that each component plays a vital role in the overall symphony of its operation. Understanding these individual elements isn’t just academic; it’s the foundation for effective truck ownership. Knowing what a particular part does allows you to better understand why a certain maintenance task is necessary or why a specific symptom might be occurring.

Based on my experience, the key to a long-lasting and reliable truck lies in proactive maintenance. This means not waiting for something to break, but rather regularly inspecting, servicing, and replacing components before they fail. For instance, knowing the function of your cooling system components will prompt you to check coolant levels and radiator health regularly. Similarly, recognizing the role of the drivetrain parts will encourage timely fluid changes and inspections for wear. for a comprehensive guide on how to stay on top of your truck’s health.

Conclusion

From the robust chassis that forms its backbone to the complex electrical system that brings it to life, every part of a truck is a testament to engineering ingenuity. This deep dive into the parts of a truck aims to demystify these incredible machines, transforming you from a passive driver into an informed and empowered owner.

By familiarizing yourself with these essential components – the engine, drivetrain, suspension, brakes, electrical system, and all the visible and hidden parts – you gain a profound appreciation for your vehicle. More importantly, you equip yourself with the knowledge to ensure your truck remains safe, reliable, and performs optimally for years to come. Remember, a well-understood truck is a well-maintained truck, and a well-maintained truck is a truck that will always get the job done. Keep learning, keep exploring, and keep your workhorse in peak condition! For more detailed technical specifications and deeper dives into automotive engineering, we recommend consulting trusted resources like reputable automotive engineering journals or manufacturer’s official technical manuals.