The Ultimate Guide to Reading Utility Body Prices: What You Need to Know Before You Buy

The Ultimate Guide to Reading Utility Body Prices: What You Need to Know Before You Buy Lmctruck.Guidemechanic.com

For any professional relying on a work truck – be it a plumber, electrician, contractor, or landscaper – a utility body isn’t just an accessory; it’s a mobile workshop. It’s the backbone of daily operations, ensuring tools are organized, secure, and readily accessible. However, navigating the landscape of utility body prices can feel like deciphering a complex code. The cost isn’t a simple flat fee; it’s a dynamic figure influenced by a myriad of factors.

This comprehensive guide is designed to demystify the "utility body cost" equation, providing you with the insights needed to make an informed purchasing decision. We’ll delve deep into the elements that dictate pricing, offer strategies for budgeting, and help you understand the true value of this essential investment. By the end of this article, you’ll be equipped to read between the lines of any service body pricing quote and select the perfect fit for your business needs and budget.

The Ultimate Guide to Reading Utility Body Prices: What You Need to Know Before You Buy

Understanding the Core Value of a Utility Body

Before we dissect the numbers, let’s acknowledge the profound value a utility body brings to your operation. It’s far more than just extra storage. A well-designed service body dramatically enhances efficiency, reduces downtime searching for tools, and projects a professional image to your clients.

Based on my experience in the commercial vehicle industry, many businesses initially balk at the investment, only to discover its invaluable return. The initial outlay for a utility body quickly pays for itself through improved productivity, reduced tool theft, and extended equipment lifespan. It transforms a standard pickup truck into a highly specialized, mobile command center.

Key Factors Influencing Utility Body Prices

The variation in "utility body prices" stems from several critical components. Understanding each of these will empower you to identify where costs are generated and how they align with your specific requirements. Let’s break down these influential factors in detail.

1. Body Material: Durability, Weight, and Cost Implications

The material chosen for your utility body is one of the most significant determinants of its overall price and performance. Each material offers a distinct balance of strength, weight, and corrosion resistance, directly impacting both the initial "service body pricing" and long-term operational costs.

Steel Utility Bodies: Steel remains a popular choice due to its exceptional durability and relative affordability. It’s incredibly robust, capable of withstanding heavy loads and rigorous daily use, making it ideal for demanding environments. However, steel bodies are heavier, which can impact fuel efficiency and reduce your truck’s available payload capacity.

When considering a steel body, you’ll find them generally at the lower end of the price spectrum compared to other materials. Their inherent strength provides peace of mind, but be mindful of maintenance – regular inspections for rust and proper coating are crucial for longevity. Many manufacturers offer various gauges of steel, with heavier gauges adding to both strength and cost.

Aluminum Utility Bodies: For those prioritizing fuel efficiency and maximum payload, aluminum utility bodies are an excellent investment. Aluminum is significantly lighter than steel, often reducing the overall weight of the truck and body by hundreds of pounds. This weight saving translates directly into better fuel economy and allows you to carry more equipment without exceeding your truck’s Gross Vehicle Weight Rating (GVWR).

While "aluminum utility body prices" are typically higher than steel, the long-term savings in fuel costs and the extended life of your truck’s suspension components can offset this initial premium. Aluminum also boasts superior corrosion resistance, making it an ideal choice for businesses operating in harsh weather conditions or near coastal areas. It requires less maintenance regarding rust prevention, adding to its appeal.

Fiberglass/Composite Utility Bodies: Fiberglass and other composite materials represent a niche but growing segment of the utility body market. These bodies are often even lighter than aluminum and can be molded into unique, aerodynamic shapes, potentially offering even greater fuel efficiency. They are also highly resistant to dents and rust.

However, composite bodies often come with a higher "utility truck body cost" and may not offer the same sheer impact resistance as steel or aluminum for heavy-duty applications. They are typically found in specialized applications where weight reduction is paramount, or specific aerodynamic properties are desired. Pro tips from us suggest carefully evaluating your application before opting for composites, ensuring they meet your strength and durability requirements.

2. Body Type and Size: Tailoring to Your Workload

The specific type and dimensions of the utility body you choose directly correlate with its "utility body pricing." A standard service body will naturally have a different cost structure than a highly specialized or enclosed unit.

Standard Service Bodies: These are the most common type, featuring external compartments and an open cargo area in the middle. They come in various lengths, typically ranging from 8 to 12 feet, designed to fit different truck chassis sizes (single rear wheel vs. dual rear wheel). The longer and wider the body, the more material and labor involved, leading to a higher price.

When evaluating standard service bodies, consider your daily operational needs. Do you need maximum compartment space or more open bed area for larger items? This balance will guide your size selection and, consequently, influence the "service body pricing."

Enclosed or Walk-In Utility Bodies: These bodies offer complete weather protection and enhanced security, essentially creating a mobile workshop. They feature a roof, walls, and often a rear door for access, allowing technicians to work inside, protected from the elements. The added materials, structural complexity, and interior finishing make these significantly more expensive than open service bodies.

The "enclosed utility body cost" can be considerably higher, but the benefits in terms of tool security, weather protection for sensitive equipment, and a comfortable working environment can be invaluable for certain trades. They are often chosen by mobile mechanics, field service technicians, and other professionals who require a secure, all-weather workspace.

Crane Bodies: Designed for heavy lifting and specialized tasks, crane bodies are built with reinforced structures to accommodate a truck-mounted crane. These are among the most expensive utility bodies due to their robust construction, integrated crane pedestals, outrigger systems, and often advanced hydraulic or electrical systems.

The "crane utility body price" will vary greatly depending on the crane’s lifting capacity, reach, and whether it’s hydraulically or electrically operated. These bodies are essential for industries like construction, utility maintenance, and heavy equipment repair, where lifting heavy components is a daily necessity.

Flatbed with Integrated Cabinets: This hybrid option combines the versatility of a flatbed with the organized storage of utility compartments. It’s an excellent choice for businesses that need to transport large, unwieldy items on the flatbed while still requiring secure storage for tools and smaller equipment.

The pricing for a flatbed with cabinets can fall between a standard service body and a full enclosed unit, depending on the extent and complexity of the integrated storage. It offers a flexible solution for diverse work requirements.

3. Features and Customization: Tailoring to Specific Needs

The level of customization and the specific features you opt for can dramatically impact "utility body prices." Every added component, specialized finish, or integrated system contributes to the final cost.

Compartment Configurations: Standard bodies come with a basic set of compartments, but you can often customize their interiors with shelves, drawers, dividers, and bins. High-quality aluminum drawers, lockable cabinets, and specialized tool holders all add to the price. The more sophisticated your internal organization system, the higher the "utility body cost."

Lighting Options: Internal compartment lighting, external work lights, and strobe lights for safety are common add-ons. LED lighting, while more expensive initially, offers superior brightness, energy efficiency, and longevity, contributing to better long-term value.

Locking Mechanisms: Basic manual locks are standard, but power locks (integrated with your truck’s central locking system) offer convenience and enhanced security, albeit at a higher price point. Keyless entry systems are also available for premium security and ease of access.

Racks and Specialized Equipment: Ladder racks, material racks for pipes or lumber, conduit carriers, and bottle trays for gas cylinders are popular additions. Liftgates for heavy item loading, air compressors, power inverters, and even generators can be integrated, each significantly increasing the "service body pricing." Pro tips from us: Carefully prioritize your essential features. Every add-on, while convenient, pushes the cost upwards.

Paint and Finish Options: A standard white or black finish is usually included, but custom colors, protective coatings (like spray-on bed liners for compartments), or graphics wraps will add to the final price. These options can enhance durability and improve your company’s branding.

4. New vs. Used Utility Bodies: Weighing the Pros and Cons

Deciding between a new or used utility body is a significant financial consideration, with each option presenting distinct advantages and disadvantages regarding "utility body prices."

New Utility Bodies: Investing in a new utility body provides peace of mind. You get the latest designs, materials, and features, often backed by a manufacturer’s warranty. A new body allows for complete customization, ensuring it perfectly meets your operational needs and integrates seamlessly with your new truck chassis.

The "new utility body cost" is undeniably higher, but it comes with the assurance of quality, no hidden wear and tear, and a longer expected lifespan. For businesses looking for a long-term investment with full control over specifications, new is often the preferred route.

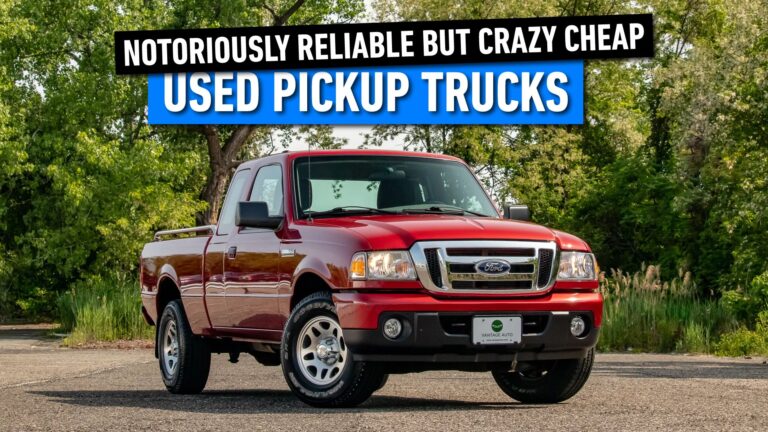

Used Utility Bodies: The primary advantage of a used utility body is significant cost savings. The "used utility body price" can be substantially lower than a new one, making it an attractive option for startups or businesses with tighter budgets. Used bodies are also often available immediately, avoiding lead times for new custom orders.

However, common mistakes to avoid when purchasing a used utility body include not thoroughly inspecting its condition. Look for signs of rust, structural damage, bent compartments, and faulty locks. Check for proper mounting hardware and ensure it’s compatible with your truck’s chassis. While cheaper, a used body might lack specific features you need or require costly repairs down the line, potentially negating initial savings. Always factor in potential refurbishment costs.

5. Manufacturer and Brand Reputation: Quality and Support

Just like with any significant purchase, the manufacturer and brand reputation play a role in "utility body pricing." Established brands with a long history of quality and innovation often command higher prices, but this premium usually comes with superior build quality, better warranty support, and higher resale value.

Researching manufacturers is crucial. Look for companies known for durable products, excellent customer service, and readily available parts. A cheaper, lesser-known brand might save you money upfront, but it could lead to headaches with premature wear, difficult-to-find replacement parts, or poor warranty claims. Investing in a reputable brand often means investing in reliability and long-term support.

6. Installation Costs: The Hidden Expense

The "utility body installation cost" is an often-overlooked component of the total price. This isn’t just about bolting the body to the truck frame; it involves integrating electrical systems, potentially hydraulics for cranes or liftgates, and ensuring proper weight distribution and safety compliance.

Professional Installation: Most utility bodies require professional installation by certified technicians. This ensures proper alignment, secure fastening, and correct wiring, which is critical for safety and functionality. The cost will vary based on the complexity of the body and any specialized features. Expect to pay several hundred to over a thousand dollars for a comprehensive installation.

DIY Installation: While some mechanically inclined individuals might consider a DIY installation for simpler bodies, it’s generally not recommended for complex units. Incorrect installation can lead to safety hazards, premature wear on the truck chassis, and voided warranties. Unless you have specialized tools and expertise, budgeting for professional installation is a wise decision.

7. Location and Dealership Markups: Regional Variations

The geographical location where you purchase your utility body can also influence the price. Shipping costs for large items like utility bodies can be substantial, impacting the final cost if the dealer is far from the manufacturer.

Furthermore, different dealerships may have varying overheads and profit margins, leading to slight differences in "service body pricing." It’s always advisable to get quotes from multiple dealers within your region to compare prices and services. Some dealerships might offer bundled deals, including installation or specific accessories, so inquire about package options.

Average Price Ranges for Different Utility Body Types (General Guidance)

Providing exact "utility body prices" is challenging due to the immense variability discussed above. However, we can offer general estimated ranges to help you budget. These figures are illustrative and can fluctuate significantly based on materials, features, and market conditions.

- Standard Steel Service Body (New, 8-10 ft): $5,000 – $12,000

- Standard Aluminum Service Body (New, 8-10 ft): $8,000 – $18,000

- Enclosed/Walk-in Utility Body (New): $15,000 – $35,000+ (depending on size and features)

- Crane Body (New, including base crane): $25,000 – $80,000+ (highly dependent on crane capacity)

- Flatbed with Integrated Cabinets (New): $6,000 – $15,000

- Used Utility Bodies: Can range from $1,500 to $10,000+, depending on age, condition, and original type.

Remember, these are starting points. Extensive customization, premium features, and specialized materials will push these figures higher.

Strategies for Budgeting and Saving on Utility Body Costs

Effectively managing "utility truck body cost" requires a strategic approach. Here are some pro tips from us to help you optimize your investment and potentially save money without compromising quality.

- Prioritize Needs vs. Wants: Create a detailed list of essential features for your daily operations. Distinguish between "must-have" items that directly impact productivity or safety and "nice-to-have" items. Focusing on core functionalities first can significantly reduce the initial "service body pricing."

- Consider Modular Components: Some manufacturers offer modular utility body systems or aftermarket add-ons. This allows you to purchase a basic body now and add specialized racks, drawers, or toolboxes later as your budget allows or needs evolve.

- Negotiate with Dealers: Don’t be afraid to negotiate. Get multiple quotes and use them as leverage. Inquire about package deals that might include installation or specific accessories at a reduced rate. Sometimes, dealers have year-end sales or promotions on specific models.

- Explore Financing Options: Many dealerships and independent lenders offer financing for commercial truck equipment. Spreading the "utility body cost" over several years can make the investment more manageable for your cash flow.

- Long-Term Maintenance: A well-maintained utility body will last longer, deferring the need for replacement. Regular cleaning, lubrication of moving parts, and prompt repairs can extend its lifespan, maximizing your initial investment.

- Assess Your Truck Chassis: Ensure your truck chassis is appropriate for the utility body you plan to install. An undersized chassis can lead to safety issues and premature wear. Check out our guide on for detailed information on this critical step.

The ROI of a Quality Utility Body

While the "utility body prices" might seem substantial upfront, it’s crucial to view this purchase as an investment with a significant return. A high-quality utility body contributes to your bottom line in multiple ways:

- Increased Productivity: Organized tools mean less time searching and more time working, directly boosting efficiency and job completion rates.

- Reduced Tool Loss and Theft: Secure compartments protect your valuable equipment, minimizing replacement costs and downtime associated with missing tools.

- Enhanced Professional Image: A tidy, well-equipped work truck projects professionalism and competence, fostering client trust and potentially leading to more business.

- Fuel Savings (with aluminum): As discussed, lighter aluminum bodies can significantly reduce fuel consumption over the vehicle’s lifespan.

- Safety Improvements: Proper storage prevents tools from shifting during transit, reducing the risk of accidents or injury.

The long-term value and operational benefits often far outweigh the initial "service body pricing," making it a smart strategic decision for any professional.

Common Mistakes to Avoid When Buying a Utility Body

Based on my experience, several common pitfalls can lead to dissatisfaction or unnecessary expenses when purchasing a utility body. Avoiding these can save you time, money, and headaches.

- Not Accurately Assessing Your Needs: The biggest mistake is buying a body that’s either too small, too large, or lacks essential features. Take the time to list every tool, piece of equipment, and material you transport daily. Consider future growth as well.

- Ignoring Weight Capacity: Overlooking the utility body’s weight and the combined weight of your tools and materials can lead to exceeding your truck’s GVWR. This is not only unsafe but also illegal and can void warranties. Always factor in the total load.

- Overlooking Installation Costs: As mentioned, assuming installation is included or free can lead to budget surprises. Always get a clear quote for installation services.

- Skipping Warranty Checks: For both new and used bodies, understand the warranty coverage. What parts are covered? For how long? What voids the warranty?

- Buying Solely on Price: While budget is important, making a decision purely on the lowest "utility body price" can lead to buying an inferior product. This often results in premature wear, costly repairs, and ultimately, a higher total cost of ownership.

- Not Considering Future Needs: If your business is growing, think about how your utility body might need to adapt in 3-5 years. Investing a little more upfront for a more versatile or expandable system can save you from having to replace it entirely later.

Future Trends in Utility Body Design and Pricing

The utility body industry is continually evolving, driven by advancements in materials, technology, and sustainability goals. Expect to see ongoing developments that could influence "utility body prices" and performance in the coming years.

Lightweight materials will continue to be a focus, with ongoing research into advanced composites that offer the strength of steel with significantly less weight. We’ll likely see more integrated smart storage solutions, perhaps with IoT capabilities for inventory management or predictive maintenance. The rise of electric work trucks will also push manufacturers to design utility bodies that are lighter, more aerodynamic, and seamlessly integrate with electric vehicle power systems. These innovations will initially come with a premium, but over time, some features may become standard, influencing overall market pricing.

Conclusion: Making an Informed Investment

Navigating the world of "reading utility body prices" doesn’t have to be overwhelming. By understanding the core factors—material, type, features, condition (new vs. used), manufacturer reputation, and installation complexities—you can make a highly informed decision. Remember that a utility body is a critical investment in your business’s efficiency, professionalism, and long-term success.

Don’t let the initial "utility truck body cost" deter you from choosing the right solution. Focus on the return on investment, the enhanced productivity, and the peace of mind that comes with a well-equipped, organized, and secure mobile workspace. Take your time, do your research, and prioritize your needs to select a utility body that will serve your business effectively for years to come. For more insights into optimizing your work truck, read our article on .

To learn more about industry standards and regulations for truck equipment, you can visit the National Truck Equipment Association (NTEA). They are a trusted resource for professionals in the work truck industry.