The Ultimate Guide to Buying Used Chevy Plow Trucks For Sale: Your Path to Winter Readiness

The Ultimate Guide to Buying Used Chevy Plow Trucks For Sale: Your Path to Winter Readiness Lmctruck.Guidemechanic.com

When winter unleashes its fury, a reliable snow plow truck isn’t just a convenience – it’s an absolute necessity for many homeowners, businesses, and contractors. Among the titans of the truck world, Chevrolet has long stood as a beacon of durability and power, making used Chevy plow trucks for sale a highly sought-after commodity. But navigating the market for a pre-owned workhorse can be tricky. This comprehensive guide will equip you with the knowledge, tips, and insights you need to make an informed purchase, ensuring you find a dependable Chevy plow truck that’s ready to tackle the harshest winters.

We’ll delve deep into what makes these trucks ideal for plowing, critical inspection points, common pitfalls to avoid, and how to secure the best deal. Our goal is to empower you to find a high-quality, long-lasting used Chevy plow truck that serves you well for many seasons to come.

The Ultimate Guide to Buying Used Chevy Plow Trucks For Sale: Your Path to Winter Readiness

Why Choose a Used Chevy Plow Truck? A Legacy of Reliability

Chevrolet trucks have earned their stripes over decades, consistently proving their mettle in demanding conditions. When it comes to snow removal, their robust construction and powerful engines make them natural contenders. Opting for a used model offers a fantastic blend of capability and cost-effectiveness.

Based on my experience in the automotive and heavy equipment sectors, a used Chevy plow truck offers significant advantages. These vehicles are engineered for tough jobs, meaning they often come with heavy-duty components that stand up well to the stresses of plowing. Their widespread popularity also means parts are readily available, and mechanics are familiar with their systems, simplifying future maintenance.

Durability and Reliability You Can Count On

Chevy trucks, particularly the Silverado HD series, are built with high-strength steel frames and robust powertrains designed to handle substantial loads and adverse conditions. This inherent durability translates directly to their performance as a plow truck, where the frame, suspension, and drivetrain are constantly under stress. A well-maintained used Chevy can easily offer many more years of service.

This structural integrity is crucial for plowing. It ensures the truck can effectively manage the weight of the plow itself, the strain of pushing heavy snow, and the additional stress on the suspension system. Many owners report exceptional longevity from their Chevy trucks, even after years of hard work.

Cost Savings Without Compromising Performance

One of the most compelling reasons to consider used Chevy plow trucks for sale is the substantial cost savings. New plow-ready trucks, complete with the plow system, can represent a significant investment. Purchasing a pre-owned model allows you to acquire a capable vehicle at a fraction of the price.

This affordability extends beyond the initial purchase. While a used truck may require some upfront maintenance, the depreciation hit has already been absorbed by the previous owner. This makes a used Chevy an excellent value proposition, especially for those who don’t need the latest technology but prioritize raw power and reliability.

Unmatched Parts Availability and Serviceability

Chevrolet’s vast market presence ensures that spare parts, from engine components to suspension parts and body panels, are widely available. This is a crucial factor for any work vehicle, particularly one that will face the rigors of plowing. When a repair is needed, you won’t be left searching endlessly for obscure parts.

Furthermore, almost every mechanic shop is familiar with Chevy trucks. This widespread expertise means that finding qualified technicians for routine maintenance or unexpected repairs is generally straightforward. This ease of serviceability contributes significantly to the long-term cost-effectiveness and operational readiness of your used plow truck.

Key Considerations Before You Buy: What to Look For

Purchasing a used plow truck requires a different mindset than buying a daily driver. You need to focus on aspects that directly impact its ability to perform under extreme stress. Our pro tips will help you pinpoint the best options among used Chevy plow trucks for sale.

Common mistakes to avoid are overlooking the truck’s fundamental mechanical condition and focusing too much on cosmetic appeal. For a plow truck, function always trumps form.

1. Truck Model and Year: Matching Power to Purpose

Not all Chevy trucks are created equal when it comes to plowing. Understanding the capabilities of different models and model years is paramount.

- Chevy Silverado 1500: While some 1500 models can accommodate lighter plows (typically straight blades up to 7.5 feet), they are generally not recommended for heavy commercial plowing. Their lighter frames and suspension components can wear out quickly under sustained stress. If your plowing needs are minimal, such as a long residential driveway, a robustly optioned 1500 might suffice, but inspect its front end carefully.

- Chevy Silverado 2500HD/3500HD: These are the true workhorses for snow removal. The "Heavy Duty" designation means they come with stronger frames, beefier suspensions, more robust axles, and higher Gross Vehicle Weight Ratings (GVWRs). For serious plowing, whether residential or commercial, an HD model is almost always the superior choice.

- Specific Model Years: Research specific model years for known issues. For instance, some generations of Duramax diesel engines or Allison transmissions are highly regarded, while others might have known quirks. Online forums and owner reviews are excellent resources for this research.

2. Engine and Drivetrain: The Heart of the Plow Truck

The engine and drivetrain are arguably the most critical components for a plow truck. They dictate its ability to push heavy snow and navigate challenging terrain.

- Gas vs. Diesel Engines:

- Gasoline Engines (e.g., 5.3L, 6.0L, 6.2L Vortec/EcoTec3): Often more affordable to purchase and maintain. They offer good low-end torque for plowing. However, they can consume more fuel under heavy loads.

- Diesel Engines (e.g., Duramax 6.6L): Renowned for their immense torque, durability, and fuel efficiency under load. They are ideal for heavy-duty, prolonged plowing operations. However, diesel trucks typically have a higher purchase price and potentially higher maintenance costs (though often less frequent). For continuous commercial plowing, the Duramax is often the top choice due to its longevity and power.

- 4×4 is Non-Negotiable: A four-wheel-drive system is absolutely essential for a snow plow truck. Without it, you’ll struggle to gain traction and push snow, especially in deeper drifts or on icy surfaces. Test the 4×4 engagement thoroughly during your inspection.

- Transmission: Most modern plow trucks come with automatic transmissions, which are generally preferred for plowing due to their ease of use and smooth power delivery. Ensure the transmission shifts smoothly, without hesitation, slipping, or harsh engagement. A robust transmission cooler is also a plus, as plowing can generate significant heat.

3. Plow Compatibility and GVWR: Safety and Performance

Understanding the truck’s Gross Vehicle Weight Rating (GVWR) and payload capacity is not just about performance; it’s about safety and legality.

- GVWR and Payload: The GVWR is the maximum permissible weight of the fully loaded truck, including the vehicle itself, passengers, cargo, and the plow system. The plow system (blade, frame, hydraulics) adds significant weight, typically 800-1200 lbs or more, directly to the front axle. Exceeding the GVWR, especially the front axle weight rating, can compromise steering, braking, and overall stability. Always ensure the truck’s capacity safely accommodates the plow.

- Plow Mounting System: Inspect the plow mount itself. Is it a well-known brand (e.g., Western, Fisher, Boss, Meyer)? Are all components present, free of severe rust, and properly aligned? The mounting frame should be securely attached to the truck’s frame, not just the bumper.

- Plow Type: While the truck is the focus, briefly consider the plow itself. Straight plows are common, V-plows offer more versatility for cutting through drifts, and push boxes are great for large lots. Ensure the plow being sold with the truck is appropriate for the truck’s capabilities.

4. Rust and Frame Integrity: The Silent Killer

Plow trucks are exposed to harsh elements, including road salt and moisture, making rust a major concern. The structural integrity of the frame is non-negotiable.

- Frame Inspection: Get underneath the truck and inspect the entire frame, especially where the plow mounts attach. Look for any signs of severe rust, pitting, cracks, or previous frame repairs. Surface rust is often cosmetic, but flaky, bubbling, or penetrating rust indicates a serious problem.

- Body Rust: Pay attention to rocker panels, wheel wells, cab corners, and the bed. While cosmetic rust can be addressed, significant rust in these areas often indicates deeper issues and can be costly to repair. A common mistake is underestimating the cost and difficulty of repairing significant rust.

5. Suspension and Tires: Handling the Load

The suspension system takes a beating when plowing. It must support the plow’s weight and absorb impacts.

- Heavy-Duty Suspension: Look for signs of heavy-duty front springs, often identifiable by their thicker coils or leaf springs. Aftermarket upgrades like helper springs, air bags, or heavier torsion bars are common and can be a good sign, indicating the previous owner invested in its plowing capability.

- Tires: The truck should have robust, aggressive-tread tires, ideally E-rated (10-ply) for heavy-duty applications. All-terrain or mud-and-snow tires are best for traction. Check for even wear, indicating proper alignment, and ensure there’s ample tread depth.

6. Electrical System: Powering the Plow

The plow’s hydraulics, lights, and controls all rely on a robust electrical system.

- Wiring Harness: Inspect the plow’s wiring harness for frayed wires, exposed connections, or amateurish splices. These can lead to intermittent failures, shorts, or even fires.

- Battery and Alternator: A plow truck places high demands on the electrical system. Ask about the age of the battery and if the alternator has been checked. A dual-battery setup is a significant plus for plow trucks, providing extra cranking power and reserve capacity.

7. Maintenance History: A Window into the Past

Always ask for service records. A well-documented maintenance history is invaluable for any used vehicle, especially a plow truck.

- Records: Look for regular oil changes, transmission services, differential fluid changes, and any repairs related to the suspension, brakes, or electrical system. This shows a diligent owner.

- No Records? Proceed with caution. While not a deal-breaker, it means you’ll need a more thorough inspection and potentially budget for immediate preventative maintenance.

The Pre-Purchase Inspection: Your Ultimate Checklist

This is where the rubber meets the road. A thorough inspection is non-negotiable when buying used Chevy plow trucks for sale. Based on my experience, skipping steps here is the fastest way to regret your purchase later.

1. Exterior and Body Inspection

- Frame: As mentioned, inspect for rust, cracks, or bends. Pay close attention to plow mount points.

- Cab and Bed: Check for rust, dents, and overall condition. Ensure the bed isn’t excessively rotted, especially if you plan to carry salt spreaders.

- Glass and Lights: Ensure all lights work (headlights, tail lights, turn signals, plow lights), and there are no significant cracks in the windshield or mirrors.

2. Engine and Drivetrain Assessment

- Fluid Leaks: Look under the truck for oil, coolant, transmission fluid, or differential fluid leaks.

- Engine Sounds: Listen for abnormal noises like knocking, ticking, or excessive exhaust leaks.

- Fluid Levels and Condition: Check engine oil (color, consistency), transmission fluid (red, not burnt smell), coolant (clean, proper level).

- 4×4 Engagement: Engage 4×4 high and low. Listen for grinding, clunking, or any resistance. Ensure the indicator light comes on.

3. Suspension and Steering Examination

- Shocks/Struts: Look for leaks or excessive bounce.

- Springs: Check for broken leaves (leaf springs) or corroded/cracked coils.

- Ball Joints and Tie Rods: Grab the wheel at 12 and 6 o’clock, then 3 and 9 o’clock, and try to rock it. Any play indicates worn components, which are common wear items on plow trucks.

- Steering Play: With the engine off, gently turn the steering wheel side to side. Excessive play before the wheels begin to turn indicates worn steering components.

4. Brake System Check

- Pads and Rotors: Visually inspect through the wheels. Look for worn pads or grooved/rusted rotors.

- Brake Lines: Check for rust, leaks, or damage to the steel and rubber lines.

5. Plow System Inspection (If Included)

- Blade: Check for excessive wear, bends, or cracks. Ensure the cutting edge is in decent condition.

- Hydraulics: Inspect all hydraulic lines for leaks, cracks, or damage. Check the hydraulic fluid reservoir. Operate the plow through its full range of motion – up, down, left, right. Listen for smooth operation.

- Plow Lights: Ensure they are fully functional and properly aimed.

- Controller: Test the plow’s in-cab controller to ensure all functions work correctly.

6. The All-Important Test Drive

- Listen and Feel: Drive on various surfaces, including bumps and turns. Listen for abnormal noises from the engine, transmission, suspension, or differentials.

- Braking: Test the brakes for firm pedal feel and straight stopping.

- Steering: Ensure the steering is responsive and doesn’t pull significantly to one side.

- Engage 4×4: Drive slowly in 4×4 on a loose surface (dirt, gravel, or snow if available) to confirm it engages and disengages smoothly.

- Operate the Plow: If possible and safe, cycle the plow through its motions during the test drive. This will reveal any hidden hydraulic or electrical issues.

7. Professional Mechanic Inspection

- Pro Tip from us: Even if you’re mechanically inclined, always invest in a pre-purchase inspection by a trusted, independent mechanic. They have specialized tools and an objective eye to spot issues you might miss. This small investment can save you thousands down the road. They can also often put the truck on a lift for a truly comprehensive underside inspection.

Where to Find Used Chevy Plow Trucks For Sale

Knowing where to look is half the battle. There are several avenues to explore when searching for your next plow truck.

- Dealerships (New and Used): Many dealerships, especially those in snowy regions, often have a selection of used plow trucks. They typically offer financing and some level of warranty, though prices might be higher.

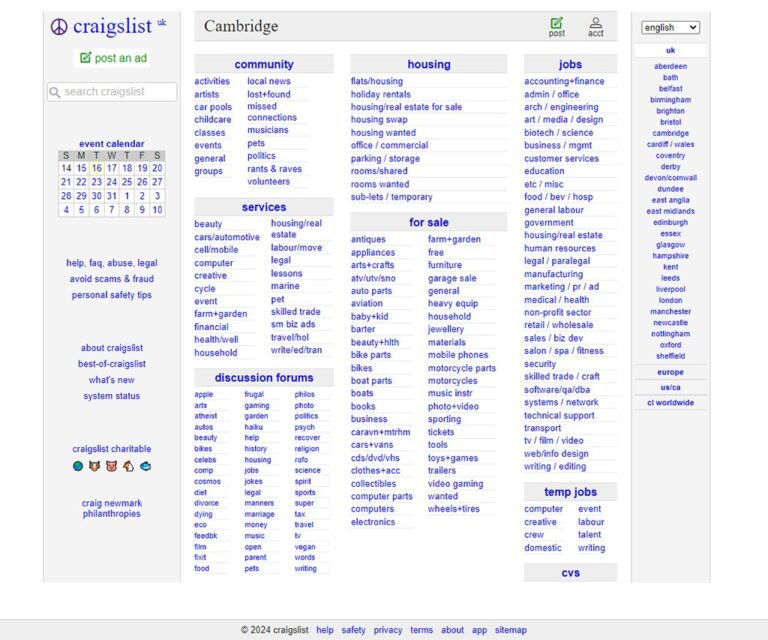

- Private Sellers: Websites like Craigslist, Facebook Marketplace, and local classifieds are popular. You can often find better deals here, but the risk is higher, and "as-is" sales are common. Be extra diligent with your inspection.

- Online Marketplaces: Dedicated automotive sites like AutoTrader, Cars.com, and eBay Motors allow you to filter searches specifically for trucks with plows.

- Auction Sites: Government surplus auctions or heavy equipment auctions can yield excellent deals, but these are often high-risk, "sight unseen" purchases for the inexperienced.

- Specialized Equipment Dealers: Businesses that sell snow removal equipment or commercial trucks often have a robust inventory of plow-ready vehicles. These dealers typically have expertise in the specific needs of a plow truck and might offer refurbished units.

Negotiation & Pricing Strategies

Researching the market value is crucial before entering negotiations for used Chevy plow trucks for sale. Use online tools to compare prices of similar models, years, and conditions.

- Know Your Budget: Set a firm maximum budget and stick to it. Remember to factor in potential immediate repairs or maintenance.

- Leverage Inspection Findings: Any issues discovered during your inspection (e.g., worn tires, suspension components, rust) become powerful negotiation points. Get quotes for repairs and use them to justify a lower offer.

- Be Prepared to Walk Away: This is your strongest negotiating tactic. If the seller isn’t willing to meet a reasonable price, or if the truck has too many red flags, be ready to move on. There are always other options.

- Common mistake to avoid: Not considering the total cost of ownership. Beyond the purchase price, budget for insurance, fuel, ongoing maintenance, and potential future repairs.

Financing Your Used Chevy Plow Truck

Securing financing for a used plow truck is similar to financing any other vehicle, but with specific considerations.

- Traditional Lenders: Banks and credit unions often offer competitive rates for used vehicle loans. Get pre-approved before you start shopping to know your buying power.

- Dealership Financing: If buying from a dealer, they will often have financing options, sometimes with special promotions. Compare their rates with your pre-approval.

- Personal Loans: For older or less expensive trucks, a personal loan might be an option, though interest rates can be higher.

- Budget for Operating Costs: Don’t forget to budget for insurance, registration, and the higher fuel costs associated with plowing. These ongoing expenses are a significant part of owning a work truck.

Post-Purchase: Essential Maintenance & Upgrades

Congratulations on your new-to-you Chevy plow truck! The journey doesn’t end with the purchase; proper post-purchase care ensures its longevity.

- Immediate Service: Even with service records, it’s wise to perform a fresh oil change, replace fuel and air filters, and check all fluid levels (transmission, differentials, transfer case, coolant). Based on my experience, a fresh start with fluids helps establish a baseline for your ownership.

- Plow System Maintenance: Thoroughly grease all plow pivot points, check hydraulic fluid levels, and inspect all electrical connections. Ensure the cutting edge is sharp or replaced if worn. Proper storage of the plow during off-season is also critical to prevent rust and component degradation.

- Rust Prevention: Apply a rust inhibitor or undercoating to the frame and vulnerable areas. Regular washing, especially after plowing, helps remove corrosive road salt.

- Potential Upgrades: Consider upgrading to LED plow lights for better visibility, adding heavier-duty springs or airbags if the front end sags with the plow, or installing a robust grille guard for added protection.

You might also be interested in: and .

For more information on specific Chevy models and their towing/hauling capabilities, refer to the official Chevrolet website: https://www.chevrolet.com/trucks/silverado/2500hd-3500hd

Conclusion: Your Reliable Winter Partner Awaits

Investing in used Chevy plow trucks for sale can be an incredibly smart decision, providing you with a powerful, dependable, and cost-effective solution for snow removal. By understanding the critical inspection points, knowing what to look for under the hood and beneath the frame, and conducting thorough research, you can confidently navigate the market. Remember, patience and a meticulous approach will pay dividends in the form of a reliable workhorse ready to conquer winter’s challenges.

Don’t settle for less when it comes to your winter readiness. Arm yourself with this guide, approach your search with confidence, and soon you’ll be the proud owner of a Chevy plow truck that’s built to last. Start your search today and prepare to make light work of heavy snow!