Mastering Truck Cap Fit On Carbon Pro: Your Expert Guide to Compatibility, Installation & Avoiding Pitfalls

Mastering Truck Cap Fit On Carbon Pro: Your Expert Guide to Compatibility, Installation & Avoiding Pitfalls Lmctruck.Guidemechanic.com

The allure of the GMC Sierra’s CarbonPro bed is undeniable. As the industry’s first carbon fiber composite pickup bed, it offers an exceptional blend of strength, durability, and reduced weight. For truck owners, this innovation represents a significant leap forward in utility and performance. However, with groundbreaking technology often comes new questions, especially when it comes to aftermarket accessories. One of the most common and crucial queries we encounter is: "Will a truck cap fit on a CarbonPro bed?"

This isn’t just a simple yes or no question. The unique properties and design of the CarbonPro bed necessitate a deeper understanding to ensure proper fitment, prevent damage, and maintain your truck’s integrity. As expert bloggers and professional SEO content writers, we’ve delved deep into this topic, drawing upon extensive experience to bring you the definitive guide. We’ll explore everything from compatibility concerns to the nuances of installation, ensuring you make an informed decision and achieve a secure, functional setup.

Mastering Truck Cap Fit On Carbon Pro: Your Expert Guide to Compatibility, Installation & Avoiding Pitfalls

Unpacking the Innovation: What Exactly is the GMC CarbonPro Bed?

Before we talk about fitting a truck cap, it’s essential to understand what makes the CarbonPro bed so unique. This isn’t your average steel or aluminum truck bed; it’s a marvel of material science, designed for the long haul.

The CarbonPro bed is constructed from a specialized carbon fiber composite material. This advanced composition grants it extraordinary resistance to dents, scratches, and corrosion – far surpassing traditional metal beds. It’s also significantly lighter, contributing to improved fuel efficiency and payload capacity. Beyond its material, the CarbonPro often features unique bed rail designs, integrated tie-downs, and sometimes even built-in power outlets, all seamlessly molded into its robust structure.

These characteristics, while highly beneficial, are precisely why fitting a standard truck cap requires careful consideration. The interaction between aftermarket accessories and this high-tech bed is not always straightforward, making proper research and installation paramount.

Why the Fitment Concern? Beyond Just "Will It Bolt On?"

Many truck owners assume that if a truck cap is designed for a specific truck model (e.g., GMC Sierra), it will automatically fit any variant of that model. While this is often true for traditional steel or aluminum beds, the CarbonPro introduces several critical factors that complicate this assumption.

Based on our experience, the primary concerns stem from three key areas:

- Material Properties and Stress Distribution: Carbon fiber composites behave differently under stress compared to metals. Over-tightening clamps or using incorrect clamping mechanisms can potentially cause localized stress points, leading to cracking or delamination over time. Unlike steel, which might bend or deform, carbon fiber can fail more catastrophically if overloaded.

- Unique Bed Rail Design: The CarbonPro bed rails might have slightly different profiles or integrated features that could interfere with standard cap mounting systems. Some traditional caps rely on a specific lip or channel on the bed rail for a secure grip, which might be absent or altered on the CarbonPro.

- Warranty Implications: Improper installation or modification of the CarbonPro bed could potentially void parts of your vehicle’s warranty. This is a significant concern for owners of a premium, technologically advanced truck. Always consult your dealer or the cap manufacturer regarding any potential warranty impacts before proceeding.

These differences mean that a "universal" approach to truck cap installation simply won’t suffice. Each step must be approached with precision and an understanding of the CarbonPro’s specific requirements.

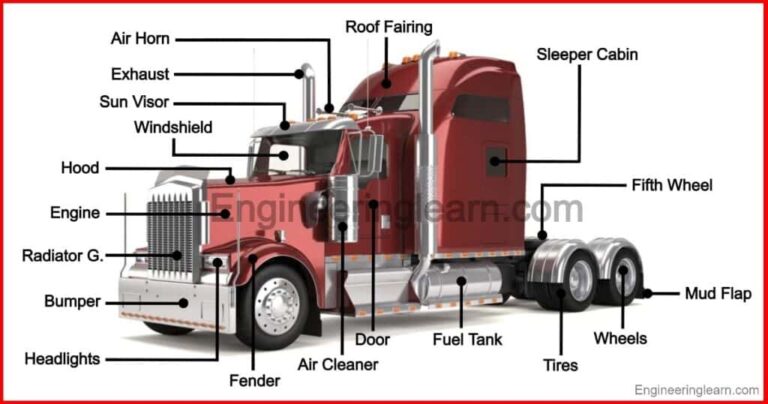

Standard Truck Caps: A Quick Overview of What We’re Working With

Before diving into the CarbonPro specifics, let’s briefly review the general characteristics of truck caps and their typical mounting methods. Understanding these basics will help highlight where the CarbonPro presents unique challenges.

Most truck caps are made from either fiberglass or aluminum. Fiberglass caps are popular for their ability to be painted to match the truck’s color, offering a seamless, integrated look. Aluminum caps, while often more utilitarian in appearance, are known for their lightweight nature and durability.

Regardless of material, the vast majority of truck caps are designed to sit on top of the truck’s bed rails. They are then secured using a series of clamps that grip the underside of the bed rail lip. Common clamp types include J-hooks, C-clamps, or specialized quick-release clamps. A foam or rubber seal is typically applied along the cap’s base to create a watertight barrier between the cap and the bed rails. This conventional setup is what needs careful adaptation for the CarbonPro.

The Crucial Question: Is a Standard Truck Cap Compatible with CarbonPro?

The short answer is yes, most standard truck caps can be fitted to a CarbonPro bed, but with significant caveats and often requiring specific attention to detail. It’s not a plug-and-play scenario. The key is to understand that "compatible" doesn’t necessarily mean "perfectly designed for."

Many leading truck cap manufacturers, such as Leer, ARE, and Snugtop, offer models that are designed to fit the GMC Sierra, including those equipped with the CarbonPro bed. However, they often have specific instructions or recommendations for CarbonPro installations.

Pro tip from us: Always confirm with both the truck cap manufacturer and a reputable dealer that the specific cap model you are considering is approved for installation on a CarbonPro bed. Don’t rely solely on the "fits GMC Sierra" label; look for explicit mention of CarbonPro compatibility. The dimensions of the CarbonPro bed rails, while similar to other Sierra models, might have slight variations that affect the cap’s seating and sealing.

Navigating the Installation Process on Your CarbonPro Bed

Installing a truck cap on a CarbonPro bed requires precision and the right approach. Rushing this process or using incorrect techniques can lead to costly damage or a leaky, insecure cap.

1. Meticulous Preparation is Key

Before even lifting the cap, proper preparation of the CarbonPro bed rails is essential. Start by thoroughly cleaning the bed rails to ensure there’s no dirt, dust, or debris that could interfere with the seal or scratch the carbon composite. Use a mild soap and water solution, then wipe dry.

Common mistakes to avoid are: skipping the cleaning step or using harsh chemicals that could damage the CarbonPro finish. A clean surface ensures optimal adhesion for seals and prevents grit from getting trapped under clamps.

2. Protecting Your CarbonPro Rails

The CarbonPro bed, while incredibly tough, is not impervious to scratches or localized pressure damage from metal clamps. We highly recommend applying protective material to the bed rails where the cap will sit and where the clamps will make contact.

This could include durable automotive-grade protective film, painter’s tape (for temporary protection during fitting), or even thin rubber pads specifically designed for this purpose. The goal is to create a buffer between the cap’s fiberglass or aluminum base and the CarbonPro, as well as between the clamp and the bed rail. This preventative measure is invaluable.

3. Gentle Cap Placement and Alignment

With the bed rails prepped, carefully lift and position the truck cap onto the bed. This is typically a two-person job due to the cap’s weight and bulk. Align the cap precisely with the contours of the bed rails, ensuring it sits evenly and squarely.

Take your time during this step. Incorrect initial placement can lead to misalignment, poor sealing, and increased difficulty during clamping. Adjust the cap until it’s perfectly centered and flush with the truck’s cab.

4. Selecting and Applying the Right Clamping Mechanisms

This is arguably the most critical step for CarbonPro beds. Standard J-hooks or C-clamps might be used, but you need to ensure they are non-marring and distribute pressure evenly. Look for clamps with wider feet or those designed with protective rubber or plastic pads.

Avoid over-tightening the clamps. Unlike steel, which has a degree of flex, carbon fiber composite can crack under excessive point pressure. Based on my experience, it’s better to tighten gradually and evenly across all clamps, then re-check after a few miles of driving. The goal is secure, not crushing. Manufacturers often provide specific torque specifications for their clamps; adhere to these diligently. A good rule of thumb is "snug, not wrench-tight."

5. Ensuring a Watertight Seal

A proper seal is vital to prevent water intrusion. Most truck caps come with a pre-installed foam or rubber bulb seal along their base. For CarbonPro beds, ensure this seal is robust and makes full contact with the bed rails.

You might need to supplement the existing seal with additional weatherstripping, particularly at the bulkhead (the front of the bed near the cab) and around the tailgate area. Pay close attention to the corners, as these are common areas for leaks. Use high-quality, adhesive-backed weatherstripping that is compatible with automotive finishes and won’t degrade the CarbonPro.

6. Electrical Connections: Brake Lights and Interior Lights

Most truck caps include a third brake light and often an interior light. These require electrical connections to your truck’s wiring system. The challenge with CarbonPro is avoiding drilling into the bed itself for wire routing.

Fortunately, many modern truck caps offer non-invasive wiring solutions. This often involves tapping into existing tail light wiring harnesses or using specialized connectors that don’t require piercing the bed. If in doubt, consult a professional installer who is familiar with CarbonPro beds and can ensure a safe, compliant electrical connection without compromising your truck’s warranty.

Common Challenges and Expert Solutions for CarbonPro Cap Fitment

Even with careful planning, specific challenges can arise when fitting a cap to a CarbonPro bed. Being aware of these and knowing the solutions will save you time and frustration.

Challenge 1: Protecting the CarbonPro Bed Rails from Scratches and Pressure Marks

- Solution: As mentioned, pre-applying clear protective film or robust protective tape (like 3M paint protection film) to the top and inner lip of the bed rails is highly effective. You can also use rubber shims or specialized clamp pads to further cushion the contact points. This is a small investment that offers significant long-term protection.

Challenge 2: Persistent Water Leaks

- Solution: Water leaks are often due to an inadequate seal, especially at the bulkhead or corners. Pro tips from us:

- Water Test: After installation, perform a water test with a hose. Spray water liberally over the cap and bed, then check inside for any leaks.

- Sealant Application: For stubborn leaks, a thin bead of automotive-grade silicone sealant can be applied under the cap’s base seal in problematic areas. Ensure the sealant is clear and designed for exterior use.

- Tailgate Seal: Don’t forget the tailgate. Many cap installations benefit from an additional tailgate seal kit to prevent water and dust from entering from below.

Challenge 3: Maintaining Your Truck’s Warranty

- Solution: The best approach is proactive communication. Before purchasing and installing a cap, speak with your GMC dealer about potential warranty implications, especially if any modifications (like drilling) are considered. Many manufacturers and dealers are now familiar with CarbonPro beds and can guide you. Choosing a reputable cap manufacturer and a certified professional installer significantly reduces the risk of warranty issues.

Challenge 4: Electrical Integration Without Damaging the Bed

- Solution: Avoid drilling into the CarbonPro bed at all costs for wiring. Look for caps and wiring kits that use existing access points or non-invasive routing methods. Many cap installers can route wiring discreetly along the truck frame or through existing grommets in the cab wall, making the connection without touching the bed itself.

Challenge 5: Uneven Pressure Distribution from Clamps

- Solution: Use as many clamps as recommended by the cap manufacturer, distributing them evenly along both sides of the bed. This spreads the load and reduces localized stress. Regularly check clamp tightness, especially after the first few hundred miles, as road vibrations can sometimes cause them to loosen slightly.

Choosing the Right Truck Cap for Your CarbonPro

Selecting the ideal truck cap goes beyond just ensuring it fits. For a CarbonPro bed, an informed choice contributes to both functionality and the longevity of your investment.

When considering materials, you generally have two main options: fiberglass and aluminum. Fiberglass caps offer a sleek, automotive-grade finish that can be color-matched to your GMC Sierra, creating a seamless look. They are often heavier but provide excellent insulation and security. Aluminum caps, on the other hand, are typically lighter, more utilitarian, and often favored for heavy-duty work or utility purposes. Their robustness can be an advantage, but their aesthetic might not appeal to everyone.

Based on my experience, for a premium truck like one with a CarbonPro bed, many owners lean towards fiberglass caps for their integrated look. However, functional needs should always dictate the choice.

Consider the features you require:

- Windows: Sliding, fixed, or pop-out, tinted for privacy.

- Lighting: Interior LED lights, often battery-powered or wired to the truck.

- Roof Racks: If you plan to carry kayaks, bikes, or ladders, ensure the cap is rated for the load and has a robust roof rack system.

- Interior Finishes: Carpeted headliners can reduce condensation and improve aesthetics.

- Security: Locking mechanisms for the rear door.

Internal Link: For a deeper dive into materials, check out our article on "Understanding Different Truck Cap Materials: Fiberglass vs. Aluminum" (placeholder link).

Finally, and perhaps most importantly, choose a reputable brand and purchase from an authorized dealer. Leading manufacturers like Leer, ARE, and Snugtop have specific models designed for the GMC Sierra and are more likely to have developed installation guidelines and compatible accessories for the CarbonPro bed. A certified dealer will also have experienced installers who understand the nuances of working with advanced materials.

Maintenance and Longevity for Your Cap and CarbonPro Bed

Once your truck cap is securely installed on your CarbonPro bed, ongoing maintenance is crucial to ensure its longevity and to protect your truck.

Regularly inspect all clamps to ensure they remain tight and secure. Vibrations from driving can sometimes loosen them over time. We recommend a visual check every few months and a re-tightening every six months or before long trips. Also, inspect the seals around the cap’s base and windows for any signs of wear, cracking, or gaps that could lead to leaks.

Cleaning your cap should be done with mild automotive soap and water, similar to how you wash your truck. Avoid abrasive cleaners or harsh chemicals that could damage the cap’s finish or the CarbonPro bed itself. Promptly address any minor issues, such as small leaks or loose hardware, to prevent them from escalating into bigger problems. This proactive approach will keep your investment protected for years to come.

The Investment: Cost Considerations

Understanding the costs involved is an important part of the decision-making process. The price of a truck cap can vary widely based on its material, features, brand, and paint matching.

- Cap Purchase Price: Fiberglass caps typically range from $1,500 to $3,500+, depending on options like windows, roof racks, and interior finishes. Aluminum caps can be slightly less, starting from $1,000 to $2,500.

- Professional Installation: While some enthusiasts attempt DIY installation, for a CarbonPro bed, professional installation is highly recommended. Expect to pay an additional $150 to $400 for expert fitting, sealing, and electrical connections. This cost is a worthwhile investment to ensure proper fitment and prevent damage to your premium truck bed.

- Additional Accessories: Factor in costs for protective bed rail tape, specialized non-marring clamps if not included, and potentially a tailgate seal kit. These add-ons are often small expenses that provide significant value in terms of protection and functionality.

Considering these costs upfront helps in budgeting and ensures you’re prepared for the full investment required for a secure and compatible setup.

Safety First: Ensuring Secure Attachment and Visibility

Beyond aesthetics and functionality, safety must always be a top priority. A securely mounted truck cap is essential for safe driving, preventing it from shifting or detaching, especially at highway speeds.

Regularly verify that all clamps are properly tightened and that the cap is firmly seated on the bed rails. This simple check can prevent serious accidents. Additionally, ensure that the cap’s third brake light is correctly wired and fully functional. This light is a crucial safety feature, signaling your braking to following drivers, especially since a truck cap often obscures the truck’s factory third brake light. Always test it after installation and periodically afterward.

Conclusion: CarbonPro and Truck Caps – A Perfect, Carefully Crafted Match

The question of whether a truck cap fits on a CarbonPro bed is indeed complex, but the answer is overwhelmingly positive: yes, it absolutely can, and beautifully so. The key lies in understanding the unique characteristics of the CarbonPro bed and approaching the cap selection and installation process with diligence and precision.

By choosing a compatible cap, utilizing proper protective measures, employing the correct clamping techniques, and ensuring a robust seal, you can successfully integrate a truck cap with your GMC Sierra’s CarbonPro bed. This combination provides enhanced utility, secure storage, and maintains the sophisticated aesthetic of your truck.

Don’t let the advanced nature of the CarbonPro bed deter you from adding a highly functional truck cap. Instead, embrace the opportunity to create a truly versatile vehicle. Always prioritize professional advice and installation to safeguard your investment and maximize the benefits of both your innovative truck bed and your new cap. For additional insights on sealing your truck bed effectively, refer to our comprehensive guide: "The Ultimate Guide to Truck Bed Sealing and Weatherproofing" (placeholder link).

Remember, a little extra care and attention during the planning and installation phases will ensure years of trouble-free use and satisfaction. For more information on the GMC CarbonPro bed’s features, you can always visit the official GMC website (external link).