Mastering the Mobile Kitchen: The Ultimate Guide to Internal Design for Your Street Food Trailer

Mastering the Mobile Kitchen: The Ultimate Guide to Internal Design for Your Street Food Trailer Lmctruck.Guidemechanic.com

Embarking on the journey of owning a street food trailer is an exciting venture, brimming with culinary possibilities and entrepreneurial spirit. However, the path to success isn’t just about crafting delicious dishes; it’s profoundly shaped by the very space where those creations come to life. The internal design of your street food trailer is more than just aesthetics; it’s the operational heart of your business, dictating efficiency, workflow, safety, and ultimately, your profitability.

As an expert in mobile kitchen setups, I’ve seen firsthand how a well-thought-out interior can transform a small space into a high-performing culinary machine. This comprehensive guide will dive deep into every aspect of internal design for your street food trailer, providing you with the insights and strategies needed to build a mobile kitchen that truly shines. We’ll cover everything from initial planning and equipment selection to material choices, ergonomics, and crucial safety considerations, ensuring your mobile eatery is not just functional, but exceptional.

Mastering the Mobile Kitchen: The Ultimate Guide to Internal Design for Your Street Food Trailer

Why Internal Design is Your Secret Sauce for Street Food Success

Many aspiring food trailer owners focus heavily on the exterior aesthetics or the menu, often overlooking the critical importance of the interior layout. This is a common oversight that can lead to significant operational hurdles down the line. A thoughtfully designed internal space is the bedrock of a successful street food business.

Beyond simply looking good, a superior internal design optimizes every aspect of your operation. It ensures a smooth workflow, minimizes wasted movement, and enhances the speed of service, which is crucial in a fast-paced environment. Moreover, it directly impacts food safety, employee comfort, and your ability to comply with stringent health regulations, all of which are non-negotiable for long-term success.

The Foundation: Planning Your Food Trailer’s Interior Layout

Before a single piece of equipment is purchased or a wall is installed, meticulous planning is paramount. This initial phase sets the stage for everything that follows, ensuring your mobile kitchen is tailored to your specific needs and culinary vision. Based on my experience, rushing this step is one of the biggest mistakes entrepreneurs make.

Concept First: Menu Dictates Design

The absolute first step in designing your food trailer’s interior is to finalize your menu. Your menu isn’t just a list of items; it’s the blueprint that dictates the type, size, and quantity of equipment you’ll need. Are you frying? Grilling? Baking? Serving cold sandwiches? Each culinary style requires specific appliances and a layout that supports its unique demands.

For instance, a trailer specializing in fried chicken will need heavy-duty fryers, robust ventilation, and ample landing space for breading and draining. Conversely, a gourmet coffee trailer will prioritize espresso machines, grinders, refrigeration for milk, and a streamlined serving counter. Pro tips from us: Create a detailed menu, down to every ingredient and preparation step. This granular approach will highlight your equipment needs and spatial requirements.

Zoning for Success: Creating Functional Workstations

Once your menu is clear, the next step is to divide your trailer’s interior into distinct functional zones. This concept, borrowed from professional kitchens, ensures a logical flow of work and prevents cross-contamination. Imagine your trailer as a series of interconnected workstations, each dedicated to a specific task.

Common zones include a hot zone (grills, fryers), a cold zone (refrigeration, salad prep), a dry storage zone, a wash zone (sinks), and a service zone (ordering, plating, pickup). The goal is to arrange these zones in a sequence that minimizes unnecessary movement for your staff, creating an efficient "kitchen triangle" on wheels. Effective zoning is critical for both speed and hygiene.

Measuring Up: Maximizing Every Inch

Street food trailers are inherently compact spaces, making accurate measurements and efficient space utilization absolutely crucial. Every inch counts, and poor planning can lead to cramped quarters, inefficient workflow, and even safety hazards. Don’t just estimate; measure everything precisely.

Consider the dimensions of your chosen equipment, the space needed for staff to move and operate comfortably, and the swing radius of doors and cabinets. Common mistakes to avoid are underestimating the space required for opening appliance doors or accessing utilities behind equipment. Creating a detailed floor plan, perhaps even a 3D mockup, can help visualize the space and identify potential bottlenecks before construction begins.

Essential Equipment: Powering Your Mobile Culinary Dreams

The equipment you choose is the backbone of your mobile kitchen. It needs to be durable, efficient, and appropriate for the demands of a high-volume, dynamic environment. Investing in the right tools from the outset will save you headaches and expenses down the road.

Cooking Appliances: The Heart of Your Kitchen

Your cooking appliances are where the magic happens. Whether it’s a flat-top griddle for smash burgers, a deep fryer for crispy fries, or a convection oven for baked goods, selection requires careful thought. Consider the BTUs (British Thermal Units) for gas appliances or wattage for electric, ensuring they meet your cooking volume needs.

Durability is key; look for commercial-grade equipment built to withstand constant use. Also, pay attention to the footprint and clearance requirements of each appliance. Based on my experience, under-sizing your cooking capacity is a frequent pitfall, leading to long wait times and frustrated customers.

Refrigeration and Storage: Keeping it Fresh and Safe

Proper refrigeration is non-negotiable for food safety and quality. Depending on your menu, you might need under-counter refrigerators, reach-in coolers, or even a small freezer. Look for NSF (National Sanitation Foundation) certified units, which meet strict public health standards.

Beyond refrigeration, adequate dry storage for non-perishable goods, packaging, and supplies is essential. Utilize vertical space with shelving and ensure all storage is clean, organized, and easily accessible. Pro tip: Plan for separate refrigeration for raw and cooked ingredients to prevent cross-contamination.

Washing and Sanitation: Non-Negotiable Hygiene

Health department regulations typically require a three-compartment sink for washing, rinsing, and sanitizing dishes and utensils, alongside a separate hand wash sink. These are critical for maintaining hygiene standards and passing inspections. Ensure you have sufficient fresh and grey water tanks to support your operations throughout the day.

The fresh water tank size is usually dictated by local regulations, often based on the number of sinks and anticipated usage. A reliable hot water heater is also a must for proper sanitation. Always check your local health department’s specific requirements for sink configurations and water capacities.

Ventilation Systems: Clear Air, Happy Crew

A robust ventilation system is crucial for removing heat, smoke, grease, and odors from your cooking area. Without it, your trailer will quickly become an uncomfortable and potentially unsafe environment for your staff. This includes an appropriately sized commercial hood with powerful exhaust fans.

The hood must extend beyond your cooking equipment to capture all fumes effectively. Furthermore, ensure proper make-up air is considered, preventing negative pressure inside the trailer. A well-designed ventilation system improves air quality, reduces fire risk, and contributes significantly to staff comfort and productivity.

Material Matters: Durability, Hygiene, and Aesthetics

The materials used for your trailer’s interior surfaces are vital for hygiene, durability, ease of cleaning, and compliance with health codes. Choosing the right materials from the start will save you countless hours in maintenance and potential issues during inspections.

Stainless Steel: The Gold Standard

For countertops, backsplashes, and often shelving, stainless steel is the undisputed champion in commercial kitchens, including food trailers. Its non-porous surface makes it incredibly hygienic, easy to clean and sanitize, and resistant to corrosion and bacteria growth. It also offers exceptional durability, standing up to the rigors of daily use.

When selecting stainless steel, look for Type 304, which offers superior corrosion resistance compared to Type 430, especially important in a damp kitchen environment. While more expensive, the investment in high-quality stainless steel pays dividends in longevity and compliance.

Flooring: Slip-Resistant and Easy to Clean

The flooring in a food trailer must be durable, slip-resistant, and easy to clean. Common choices include commercial-grade vinyl flooring with a non-slip texture or diamond plate aluminum. Both options are designed to withstand heavy foot traffic, spills, and constant cleaning.

Safety should be your top priority here. A slip-resistant floor significantly reduces the risk of accidents for your staff. Ensure the flooring extends up the walls slightly (coved flooring) to create a seamless, easy-to-clean junction, preventing grime buildup in corners.

Walls and Ceilings: Bright, Clean, and Compliant

For walls and ceilings, materials that are smooth, washable, and light-colored are typically required by health departments. Fiberglass Reinforced Plastic (FRP) panels are a popular choice due to their moisture resistance, durability, and ease of cleaning. Aluminum sheeting is another excellent option, offering a sleek, professional look and similar benefits.

Light-colored surfaces also help reflect light, making the interior brighter and feel more spacious, which is a significant advantage in a compact environment. Ensure all seams are properly sealed to prevent moisture ingress and pest harborage.

Ergonomics and Workflow: Designing for Efficiency and Comfort

Ergonomics is the science of designing equipment and workspaces to fit the human body, maximizing efficiency and minimizing discomfort or injury. In a street food trailer, where space is limited and movement is constant, ergonomic design is crucial for staff well-being and operational speed.

Streamlining Movement: The Kitchen Triangle on Wheels

Just like in a traditional kitchen, the "kitchen triangle" concept applies to food trailers, though on a much smaller scale. This involves strategically placing your primary workstations – prep, cooking, and washing – in a way that minimizes steps between them. The goal is to create a logical flow that reduces unnecessary turning, bending, and reaching.

Think about the sequence of tasks: grab ingredients, prep, cook, plate, serve. Your layout should support this flow seamlessly, allowing staff to perform their duties with minimal wasted motion. Pro tip: Walk through your imagined workflow mentally, or even physically in a mock-up, to identify inefficiencies.

Counter Height and Workspace: Comfort for Your Crew

Standard counter heights typically range from 34 to 36 inches, but consider the average height of your staff when designing prep areas. Providing adequate counter space for chopping, assembling, and plating is vital. Cramped workspaces lead to frustration, slower service, and increased risk of accidents.

If possible, incorporate adjustable height tables or varied counter heights for different tasks. Ensure there’s enough clearance above and below counters for comfortable standing and legroom, especially if stools are used during downtime.

Storage Solutions: Smart Space Utilization

Effective storage is a game-changer in a small mobile kitchen. Utilize every available space, from under-counter cabinets to overhead shelving. Magnetic knife strips save drawer space and keep essential tools within easy reach. Wall-mounted racks for spices or frequently used utensils are also excellent space-savers.

Consider pull-out drawers for easy access to ingredients or small equipment, and ensure all storage is organized and labeled. Common mistake: Overlooking vertical space. Wall-mounted shelves and even ceiling-mounted pot racks can significantly increase storage capacity without encroaching on floor space.

Powering Your Operation: Electrical and Plumbing Considerations

The electrical and plumbing systems are the unseen infrastructure that keeps your mobile kitchen running. These systems must be robust, reliable, and expertly installed to prevent breakdowns, ensure safety, and comply with strict regulations.

Electrical Systems: The Lifeblood of Your Trailer

Your electrical system needs to handle the cumulative load of all your appliances, lighting, and refrigeration. You’ll need to decide between relying primarily on a generator, shore power (plugging into an external power source), or a combination of both. A professional electrician specializing in mobile applications should design and install your system.

This includes calculating your total power draw, selecting appropriate wiring gauges, breaker sizes, and outlet placements. Proper grounding and safety cut-offs are non-negotiable. Based on my experience, underestimating your power needs is a common pitfall, leading to tripped breakers and operational interruptions.

Plumbing Systems: Water In, Water Out

The plumbing system manages your fresh water supply, hot water, and greywater (wastewater) disposal. This involves appropriately sized freshwater and greywater tanks, a reliable water pump, and a hot water heater. All plumbing lines must be securely installed and protected from freezing temperatures if you plan to operate in colder climates.

Proper venting for the greywater tank is essential to prevent odors and ensure smooth drainage. Additionally, consider an easily accessible external fill port for your freshwater tank and a convenient drain for your greywater, often with a valve for controlled disposal. Health departments have very specific requirements for plumbing, so working with a licensed professional is key.

Safety First: Designing for Compliance and Protection

Safety is paramount in any commercial kitchen, and a food trailer is no exception. Due to the confined space and the presence of open flames, hot surfaces, and electrical equipment, designing for safety and compliance is critical to protect your staff, customers, and business.

Fire Suppression Systems: A Must-Have

For any trailer with cooking equipment that produces grease-laden vapors (e.g., fryers, griddles), a commercial fire suppression system (like an Ansul system) is not just recommended, it’s typically legally required. This system automatically detects and extinguishes fires, providing a crucial layer of protection. Ensure it’s regularly inspected and maintained.

Emergency Exits and Accessibility

While a food trailer typically has one main service window/door, ensure that there are clear pathways for staff movement and, if necessary, an easily accessible emergency exit. Keep aisles free of obstructions. The design should allow for quick evacuation in case of an emergency, and comfortable access for all staff members.

Health Code Compliance: Your Blueprint for Approval

Every aspect of your internal design must comply with local, state, and national health codes. These regulations cover everything from sink requirements and water tank sizes to ventilation, material choices, and pest control. Failing to meet these standards can result in hefty fines, operational shutdowns, and a damaged reputation.

Pro tips from us: Before you even start building, obtain a copy of your local health department’s specific requirements for mobile food units. Engage with health inspectors early in the design process to ensure your plans will be approved. You can often find valuable resources on your local health department’s website or national organizations like the FDA. For example, the U.S. Food & Drug Administration’s Food Code offers comprehensive guidelines that many local jurisdictions adapt.

Pro Tips for a Winning Internal Design

- Hire Professionals: While DIY can save money, critical systems like electrical, plumbing, and fire suppression should always be handled by certified professionals. Consider hiring a food truck builder or designer who specializes in mobile kitchens.

- Don’t Skimp on Quality: Investing in commercial-grade, durable equipment and materials might seem more expensive initially, but it will save you significant repair and replacement costs in the long run. Quality equals reliability.

- Future-Proofing: Think about potential menu expansions or changes down the road. Can your current layout accommodate a new piece of equipment or a different workflow without a complete overhaul? Design with a degree of flexibility.

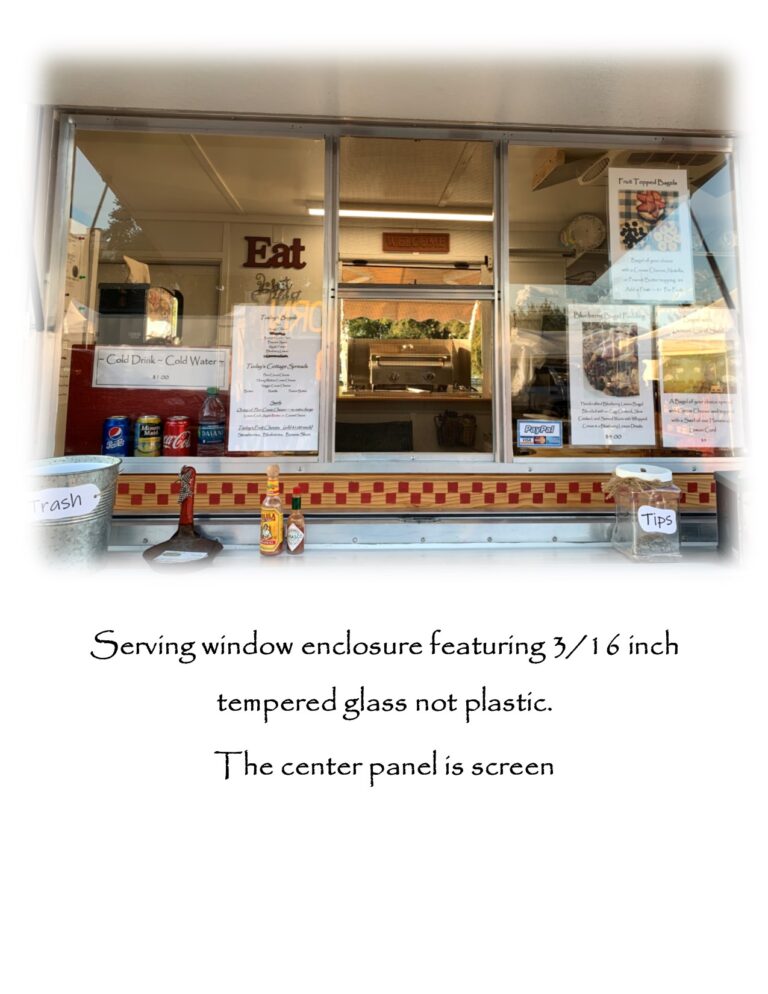

- Customer-Facing Area: Don’t forget the service window and customer interaction space. Ensure your menu board is clear, the serving window is at a comfortable height, and there’s a designated area for condiments and napkins. (placeholder) could provide more insights here.

Common Mistakes to Avoid When Designing Your Food Trailer Interior

- Not Planning Enough: Rushing the design phase inevitably leads to costly changes and operational inefficiencies later on. Take your time to plan meticulously.

- Overstuffing Equipment: Resist the urge to pack too much equipment into a small space. This creates a cramped, inefficient, and potentially unsafe working environment. Prioritize essential items.

- Ignoring Health Codes: This is perhaps the biggest mistake. Health code violations can shut down your business before it even starts. Always consult local regulations early and often.

- Poor Ventilation: Inadequate ventilation leads to uncomfortable working conditions, excessive heat, and the buildup of grease and odors, affecting both staff and food quality.

- Lack of Maintenance Access: Ensure there’s enough space around and behind equipment for cleaning, maintenance, and repairs. Blocking access can turn simple fixes into major headaches.

Conclusion: Your Mobile Culinary Empire Awaits

Designing the internal layout of your street food trailer is an intricate process, but it’s an investment that will pay dividends in efficiency, safety, and customer satisfaction. By meticulously planning your space, selecting the right equipment and materials, prioritizing ergonomics, and adhering to strict safety and health regulations, you’re not just building a kitchen; you’re crafting the foundation for a thriving mobile culinary business.

Remember, your food trailer is more than just a vehicle; it’s your mobile command center, your workshop, and your stage. A well-designed interior empowers you and your team to deliver exceptional food and service, day after day. So, roll up your sleeves, start planning, and get ready to create a mobile kitchen that truly sets you apart. Your culinary empire on wheels is within reach – design it to succeed! (placeholder) can help you spread the word once your dream kitchen is ready.