Mastering the Mighty "Truck In 26": Your Ultimate Guide to Heavy-Duty Hauling

Mastering the Mighty "Truck In 26": Your Ultimate Guide to Heavy-Duty Hauling Lmctruck.Guidemechanic.com

The world of commercial trucking is vast and complex, filled with specialized vehicles designed for specific tasks. Among these, the term "Truck In 26" often surfaces, referring to a critical category of heavy-duty vehicles that form the backbone of countless industries. Whether you’re a seasoned fleet manager, an aspiring owner-operator, or simply curious about the logistics that drive our economy, understanding the nuances of these trucks is paramount.

This comprehensive guide is your definitive resource for navigating the landscape of "Truck In 26." We’ll delve deep into what this classification truly means, explore its diverse applications, uncover the operational intricacies, and equip you with the knowledge to make informed decisions. Our goal is to provide a pillar of content that not only educates but also empowers you with expert insights.

Mastering the Mighty "Truck In 26": Your Ultimate Guide to Heavy-Duty Hauling

Unpacking "Truck In 26": What Does It Truly Signify?

The phrase "Truck In 26" isn’t always a universally standardized term, which can lead to some initial confusion. However, in the professional trucking world, it most commonly refers to a commercial vehicle’s weight classification. Specifically, it often denotes a truck with a Gross Vehicle Weight (GVW) of approximately 26,000 pounds (lbs) in North America, or a 26-metric-ton (26,000 kg) truck in regions using the metric system, such as Europe and parts of Asia.

Understanding this distinction is crucial, as the operational requirements, licensing, and typical applications can vary significantly between these interpretations. Both, however, represent substantial heavy-duty vehicles capable of serious work. We will explore both facets to ensure a complete understanding.

The 26,000 lbs GVW Truck: A North American Powerhouse

In the United States and Canada, a "Truck In 26" often implies a vehicle with a Gross Vehicle Weight (GVW) rated at 26,000 pounds. This places it squarely in Class 6 of the North American truck classification system, which covers vehicles ranging from 19,501 to 26,000 lbs GVW. These trucks are a sweet spot for many businesses, offering significant hauling capacity without always requiring the highest level of commercial driver’s license.

These vehicles are typically single-unit, straight trucks, meaning the cab and cargo area are on a single frame, without an articulating trailer. Their versatility makes them indispensable for a wide array of local and regional operations. From beverage delivery to refuse collection, they fill a vital niche in the supply chain.

The 26-Metric-Ton Truck: European and International Heavy Lifters

When you hear "Truck In 26" in a European context, it almost certainly refers to a vehicle with a Gross Vehicle Weight of 26 metric tons (26,000 kg). This is a significantly heavier class of vehicle than its 26,000 lbs counterpart, roughly equivalent to 57,320 lbs. These trucks often fall into the heavy goods vehicle (HGV) category and are capable of carrying very substantial payloads.

These rigid vehicles are common sights on European roads, used for everything from construction materials transport to long-haul distribution of goods. The higher weight capacity means they are designed for more demanding tasks and often require more robust engineering and stricter driver qualifications. For the remainder of this article, we will primarily focus on the characteristics and operational aspects that apply broadly to heavy-duty trucks in this range, while highlighting specific differences where relevant.

Core Characteristics and Engineering of "Truck In 26" Vehicles

Regardless of whether we’re talking about 26,000 lbs or 26 metric tons, these trucks are engineered for durability, power, and efficiency. They are purpose-built machines designed to withstand the rigors of commercial use day in and day out. Understanding their key components helps appreciate their capability.

Robust Powertrain: Engines and Transmissions

The heart of any "Truck In 26" is its powertrain. You’ll find a variety of diesel engines, known for their torque and longevity, specifically designed for heavy-duty applications. These engines are calibrated to deliver consistent power output, essential for moving heavy loads and navigating diverse terrains. Engine sizes typically range from 6 to 13 liters, depending on the GVW and intended application.

Transmissions come in both manual and automatic options. Manual transmissions, often with 6 to 13 speeds, offer drivers greater control over power delivery and fuel economy, especially in varied driving conditions. However, automatic and automated manual transmissions (AMTs) are increasingly popular due to their ease of operation, reduced driver fatigue, and advanced electronic controls that optimize shifting for efficiency and performance.

Durable Chassis and Frame Construction

The backbone of a "Truck In 26" is its chassis and frame. These are constructed from high-strength steel alloys, designed to absorb significant stress from heavy loads, road imperfections, and continuous operation. The frame rails are typically deep and thick, providing torsional rigidity and resistance to bending. This robust construction is crucial for maintaining vehicle integrity and ensuring safety under maximum load.

Manufacturers often offer various frame rail thicknesses and reinforcement options to suit specific vocational requirements. For instance, a dump truck application will require a much heavier-duty frame than a lighter delivery truck, even if both fall within the "Truck In 26" category. This customization ensures the vehicle can handle its intended purpose without premature wear or failure.

Advanced Braking Systems

Given the significant weight these trucks carry, powerful and reliable braking systems are non-negotiable. Air brakes are standard on most heavy-duty "Truck In 26" vehicles, providing superior stopping power and consistent performance compared to hydraulic systems for heavier loads. These systems often include ABS (Anti-lock Braking System) and sometimes Electronic Stability Control (ESC) to enhance safety and prevent jackknifing or loss of control, especially in adverse conditions.

Engine brakes or exhaust brakes are also common features, particularly on larger "Truck In 26" models (like the 26-metric-ton variant). These systems assist in slowing the vehicle by using the engine’s compression, significantly reducing wear on the service brakes and improving safety on long descents. Based on my experience, regularly checking your air brake system for leaks and proper adjustment is one of the most critical preventative maintenance tasks for any heavy truck.

Cab Configurations and Driver Comfort

Driver comfort and ergonomics are increasingly prioritized in modern "Truck In 26" designs. Cabs range from basic day cabs, suitable for local routes where drivers return home daily, to extended cabs or even small sleepers for regional hauls. Features like air-ride seats, adjustable steering columns, intuitive dashboard layouts, and advanced climate control contribute to driver well-being, which is vital for safety and productivity.

Modern cabs also integrate advanced infotainment systems, navigation, and telematics equipment. These technologies not only improve the driving experience but also provide critical data for fleet management and compliance. A comfortable driver is a safer and more efficient driver, directly impacting operational success.

Diverse Applications: Where "Truck In 26" Shines

The versatility of "Truck In 26" vehicles makes them indispensable across a multitude of industries. Their capacity to carry substantial loads while often maintaining a relatively manageable footprint for urban environments makes them a preferred choice for many operations.

Here are some of the most common applications:

- Local and Regional Delivery: This is arguably the largest sector for 26,000 lbs GVW trucks. Companies delivering food, beverages, parcels, retail goods, and other commodities rely heavily on these vehicles for efficient last-mile and regional distribution. Their maneuverability in urban areas combined with significant payload capacity is ideal.

- Construction and Vocational Services: In the construction industry, "Truck In 26" can take many forms:

- Dump Trucks: Used for hauling aggregates, dirt, sand, and debris to and from job sites.

- Flatbed Trucks: Often equipped with cranes or lift gates for transporting building materials, equipment, and machinery.

- Service Trucks: Mobile workshops for mechanics, utility crews, and other field service professionals.

- Waste Management: Refuse collection vehicles, particularly front and side loaders, often fall into the "Truck In 26" category (especially the 26-metric-ton variants). These trucks are built to handle extremely heavy and often unevenly distributed loads daily.

- Utility Services: Power companies, telecommunications providers, and municipal utility departments utilize these trucks for carrying specialized equipment, tools, and personnel to maintenance and repair sites. Bucket trucks and digger derricks are common examples.

- Specialized Transport: From moving heavy machinery for rental companies to transporting specialized equipment for events, "Truck In 26" vehicles offer the muscle and adaptability needed for niche hauling tasks.

- Beverage Distribution: These trucks are a common sight for breweries, soft drink companies, and water distributors. They are designed to carry very heavy, palletized loads of liquid products efficiently to stores and restaurants.

Driver Requirements and Licensing for "Truck In 26"

Operating a heavy-duty vehicle like a "Truck In 26" requires specialized skills and, crucially, the correct driver’s license. The specific requirements vary significantly depending on the vehicle’s GVW and the country or region of operation.

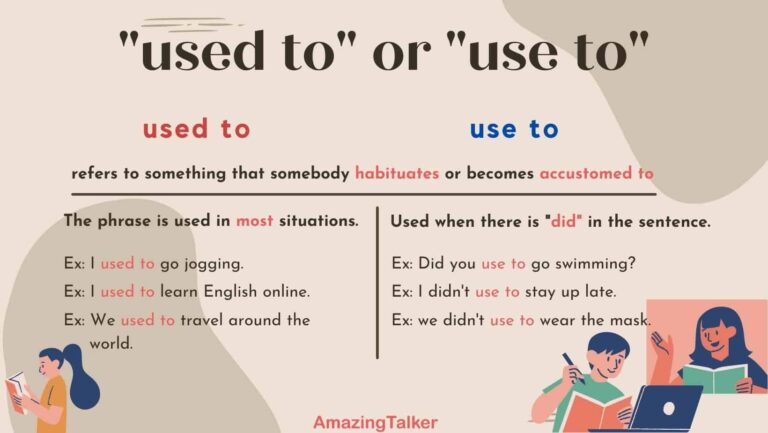

North American CDL Requirements (26,000 lbs GVW)

In the United States, driving a truck with a GVW of 26,001 lbs or more requires a Commercial Driver’s License (CDL). However, a "Truck In 26" with a GVW exactly at 26,000 lbs often falls into a unique category. If the GVW is under 26,001 lbs, a Class B CDL is typically required if the vehicle is designed to transport 16 or more passengers (including the driver), or if it’s transporting hazardous materials.

Crucially, for a straight truck not carrying hazardous materials and not transporting 16+ passengers, if its GVW is exactly 26,000 lbs or less, it might not require a CDL in some states. However, this is a grey area and highly dependent on state-specific regulations and the exact nature of the load. Pro tips from us: Always verify the specific CDL requirements with your local Department of Motor Vehicles (DMV) or equivalent authority. When in doubt, obtaining a Class B CDL is the safest and most compliant option for a vehicle of this size. It opens up more opportunities and ensures you’re legally covered.

For a deeper dive into CDL requirements and endorsements, you might find our article on extremely helpful.

European & International Licensing (26-Metric-Ton GVW)

In Europe and many other parts of the world, a truck with a 26-metric-ton GVW falls under the Category C (Heavy Goods Vehicle) license. This is a much more demanding license than a standard car license (Category B) and typically involves extensive training, theory tests, and practical driving examinations. It signifies the driver’s competence to operate large, heavy vehicles safely.

Specific endorsements might also be required depending on the type of cargo (e.g., ADR for dangerous goods) or if the vehicle is equipped with specialized equipment like a crane. These rigorous requirements underscore the significant responsibilities associated with operating such powerful machinery.

Training, Endorsements, and Continuous Professional Development

Beyond the basic license, specialized training is often beneficial, if not mandatory, for certain operations. This includes training for operating specific equipment (like boom lifts or forklifts), defensive driving courses, and hazmat training. Many regions also have requirements for ongoing professional development or periodic refreshers for commercial drivers.

Common mistakes to avoid are assuming your standard car license is sufficient for any "Truck In 26" or neglecting to stay updated on changing regulations. Penalties for operating without the correct license can be severe, including hefty fines, vehicle impoundment, and even imprisonment.

Choosing the Right "Truck In 26" for Your Operation

Selecting the ideal "Truck In 26" is a significant investment and a decision that impacts efficiency, profitability, and safety. It requires a thorough assessment of your specific needs and a careful evaluation of available options.

1. Assess Your Payload and Cargo Type

This is the foundational step. What are you primarily hauling?

- Weight: How heavy are your typical loads? This determines the necessary GVW and payload capacity. Remember to factor in the weight of the truck body itself (e.g., a refrigerated box vs. a dry van).

- Volume: How much space do you need? This dictates the length and height of the cargo body.

- Nature of Cargo: Is it palletized, loose, refrigerated, liquid, or hazardous? This influences the type of body (e.g., dry van, reefer, tanker, flatbed, dump), special features (e.g., liftgate, crane, tie-downs), and interior finishes.

2. Consider Your Operating Environment and Routes

Where will the truck primarily operate?

- Urban vs. Highway: Urban routes demand greater maneuverability, tighter turning radii, and better visibility. Highway driving emphasizes fuel efficiency, driver comfort for long stretches, and cruising power.

- Terrain: Hilly areas require more powerful engines and robust braking systems. Off-road or construction site access might necessitate higher ground clearance, all-wheel drive, and specialized tires.

- Climate: Extreme temperatures (hot or cold) influence engine cooling, battery performance, and cab climate control needs.

3. New vs. Used: Budget and Longevity

Your budget will heavily influence this decision.

- New Trucks: Offer the latest technology, better fuel efficiency, full warranties, and often more customization options. The upfront cost is higher, but depreciation and maintenance costs are generally lower in the initial years.

- Used Trucks: Present a lower entry cost, making them attractive for smaller businesses or specific short-term projects. However, they might come with higher maintenance risks, less fuel efficiency, and potentially outdated technology. Based on my experience, when buying used, a comprehensive pre-purchase inspection by a trusted mechanic is non-negotiable. Check maintenance records meticulously.

4. Total Cost of Ownership (TCO)

Look beyond the sticker price. TCO includes:

- Fuel Consumption: A major ongoing expense.

- Maintenance and Repairs: Factor in scheduled service, parts, and labor.

- Insurance: Heavy trucks carry higher premiums.

- Tires: A significant recurring cost.

- Driver Wages and Benefits: If applicable.

- Depreciation: The loss of value over time.

- Regulatory Compliance Costs: Permits, inspections, etc.

5. Manufacturer Reputation and Support

Choosing a reputable manufacturer with a strong dealer network and readily available parts is crucial. Good after-sales support can significantly reduce downtime and operational headaches. Consider brands known for their reliability in your specific application.

6. Customization and Body Upfitting

Many "Truck In 26" chassis are sold as "cab and chassis" units, ready for specialized body upfitting. Work with experienced upfitters to ensure the body is perfectly matched to your operations and complies with all weight distribution and safety regulations.

Operational Excellence and Best Practices for "Truck In 26"

Operating a "Truck In 26" safely and efficiently is an art form, honed through experience and adherence to best practices. Maximizing uptime and minimizing costs are key to a profitable trucking operation.

Pre-Trip Inspections: The Daily Ritual

Every commercial driver knows the importance of a thorough pre-trip inspection. This isn’t just a regulatory requirement; it’s a critical safety measure.

- Lights and Signals: Check all headlights, taillights, brake lights, turn signals, and hazard lights for proper function.

- Tires: Inspect tire pressure, tread depth, and look for any cuts, bulges, or foreign objects.

- Brakes: Verify air brake pressure, check for leaks, and ensure brake components are in good condition.

- Fluids: Check oil, coolant, power steering fluid, and windshield washer fluid levels.

- Cargo Securement: Ensure the load is properly secured and distributed according to weight limits.

- Mirrors and Windshield: Clean and adjust for optimal visibility.

Common mistakes to avoid are rushing the pre-trip inspection or skipping it altogether. A small issue caught before departure can prevent a major breakdown or accident on the road.

Weight Distribution and Loading Safety

Proper weight distribution is paramount for safety, handling, and preventing undue stress on the vehicle’s components. Overloading or uneven loading can lead to:

- Loss of Control: Especially during braking or cornering.

- Tire Blowouts: Due to excessive pressure.

- Suspension Damage: Leading to costly repairs.

- Frame Cracks: A severe structural issue.

Always adhere to the truck’s Gross Vehicle Weight Rating (GVWR) and Gross Axle Weight Ratings (GAWRs). Use scales to verify your loaded weight. Pro tips from us: Train your loading crews thoroughly on weight distribution principles and securement techniques. Invest in proper tie-downs, straps, and dunnage to prevent cargo shifting.

Preventative Maintenance: Your Best Investment

Regular, scheduled preventative maintenance is the cornerstone of a reliable fleet. It’s far more cost-effective to prevent a breakdown than to react to one.

- Follow Manufacturer Schedules: Adhere to recommended service intervals for oil changes, filter replacements (oil, fuel, air), fluid checks, and component inspections.

- Tire Management: Rotate tires, check alignment, and monitor wear patterns.

- Brake Servicing: Regular inspections and replacement of pads/linings, drums/rotors, and air system components.

- Lubrication: Proper greasing of chassis components extends their lifespan.

You can learn more about comprehensive fleet maintenance strategies in our article: .

Fuel Management and Efficiency

Fuel is often the largest operational expense. Implementing strategies to optimize fuel consumption can lead to significant savings.

- Driver Training: Educate drivers on efficient driving techniques, such as smooth acceleration, anticipating traffic, and avoiding excessive idling.

- Route Optimization: Utilize GPS and fleet management software to plan the most efficient routes, avoiding unnecessary mileage and traffic congestion.

- Aerodynamics: For larger box trucks, aerodynamic fairings can reduce drag and improve fuel economy.

- Tire Pressure: Maintaining correct tire pressure is vital for fuel efficiency and tire longevity.

The Future of "Truck In 26": Innovation on the Horizon

The trucking industry is in constant evolution, driven by technological advancements, environmental concerns, and a demand for greater efficiency. "Truck In 26" vehicles will undoubtedly be at the forefront of these transformations.

Electrification and Alternative Fuels

The push for greener transportation is leading to the development of electric "Truck In 26" models. Battery-electric trucks (BETs) offer zero tailpipe emissions and quieter operation, making them ideal for urban delivery routes. Hydrogen fuel cell trucks are also emerging as a viable long-haul alternative, offering longer ranges and faster refueling times than BETs.

Beyond full electrification, hybrid systems and alternative fuels like natural gas (CNG/LNG) continue to offer pathways to reduced emissions and operational costs. These innovations promise a cleaner, more sustainable future for trucking.

Advanced Driver-Assistance Systems (ADAS)

Modern "Truck In 26" vehicles are increasingly equipped with sophisticated ADAS features that enhance safety and reduce driver fatigue. These include:

- Adaptive Cruise Control (ACC): Automatically adjusts speed to maintain a safe following distance.

- Lane Departure Warning (LDW) and Lane Keeping Assist (LKA): Alert drivers if they drift out of their lane and can even provide gentle steering correction.

- Automatic Emergency Braking (AEB): Detects potential collisions and applies brakes autonomously if the driver doesn’t react.

- Blind Spot Monitoring (BSM): Warns drivers of vehicles in their blind spots.

These systems act as a second pair of eyes, significantly improving road safety for truckers and other road users.

Telematics and Fleet Management

Telematics systems have become indispensable for modern fleet operations. They provide real-time data on:

- Vehicle Location and Tracking: For optimized dispatch and delivery schedules.

- Driver Performance: Monitoring speed, harsh braking, and idling to identify areas for training.

- Engine Diagnostics: Proactive identification of mechanical issues, enabling predictive maintenance.

- Fuel Consumption: Detailed analysis to pinpoint inefficiencies.

This data empowers fleet managers to make data-driven decisions, improve efficiency, enhance safety, and ensure regulatory compliance.

Navigating the Regulatory Landscape and Compliance

Operating a "Truck In 26" involves adhering to a complex web of regulations designed to ensure safety, protect the environment, and maintain fair competition. Compliance is not optional; it’s a fundamental requirement for any commercial trucking operation.

Department of Transportation (DOT) Regulations (US)

In the United States, the Federal Motor Carrier Safety Administration (FMCSA), a division of the DOT, sets comprehensive regulations for commercial motor vehicles (CMVs). These include rules pertaining to:

- Driver Qualifications: Licensing, medical fitness, drug and alcohol testing.

- Hours of Service (HOS): Limits on driving and on-duty time to prevent driver fatigue.

- Vehicle Maintenance and Inspection: Regular safety checks and record-keeping.

- Hazardous Materials Transport: Specific requirements for handling, placarding, and documentation.

- Drug and Alcohol Clearinghouse: A national database to identify drivers who are prohibited from operating CMVs.

Ignorance of these regulations is not an excuse. Common mistakes to avoid are neglecting proper record-keeping for HOS logs or maintenance, and failing to conduct mandatory drug and alcohol tests. For official guidance, always refer to the FMCSA website, which is an invaluable external resource: External Link: FMCSA Official Website.

Emissions Standards

Environmental regulations are increasingly stringent globally. "Truck In 26" vehicles must comply with emissions standards (e.g., EPA standards in the US, Euro emissions standards in Europe) designed to reduce pollutants like nitrogen oxides (NOx) and particulate matter (PM). This often involves technologies such as Diesel Particulate Filters (DPF) and Selective Catalytic Reduction (SCR) systems, which require Diesel Exhaust Fluid (DEF). Proper maintenance of these systems is crucial for compliance and avoiding costly fines.

Weight Limits and Permits

Beyond the vehicle’s GVWR, there are legal weight limits for axles and total vehicle weight on specific roads and bridges. Exceeding these limits can result in fines, damage to infrastructure, and safety hazards. Some oversized or overweight loads may require special permits, route planning, and even pilot escorts. It’s imperative to understand and adhere to these limits for every journey.

Insurance Requirements

Commercial trucks require specialized insurance policies that differ significantly from personal auto insurance. These policies cover liability for accidents, cargo damage, and physical damage to the vehicle itself. The level of coverage required often depends on the type of operation, the cargo being hauled, and regulatory mandates. Adequate insurance is not just a legal requirement but a financial safeguard for your business.

Conclusion: Driving Forward with "Truck In 26" Expertise

The "Truck In 26" category, whether referring to a 26,000 lbs GVW vehicle or a 26-metric-ton heavy goods vehicle, represents a cornerstone of modern logistics and industry. From the bustling streets of our cities to the demanding terrains of construction sites, these versatile workhorses keep our economies moving.

By understanding their core characteristics, diverse applications, driver requirements, and the critical operational and regulatory considerations, you are better equipped to navigate this essential segment of the trucking world. We hope this comprehensive guide has provided you with invaluable insights and actionable knowledge. Remember, success in trucking hinges on continuous learning, meticulous planning, and an unwavering commitment to safety and efficiency.

Equip yourself with the right knowledge, make informed decisions, and drive your operations forward with confidence. The "Truck In 26" is more than just a truck; it’s a vital component of progress.