Heavy Duty Hand Trucks For Sale: Your Ultimate Guide to Moving Mountains Safely and Efficiently

Heavy Duty Hand Trucks For Sale: Your Ultimate Guide to Moving Mountains Safely and Efficiently Lmctruck.Guidemechanic.com

Moving heavy objects isn’t just a chore; it’s a science of leverage, safety, and efficiency. Whether you’re managing a bustling warehouse, running a busy delivery service, or tackling a serious home renovation project, the right equipment can transform a back-breaking task into a manageable one. This is where heavy duty hand trucks come into their own, acting as indispensable allies in material handling.

Finding the perfect heavy duty hand trucks for sale can feel overwhelming with the sheer variety available. This comprehensive guide is designed to cut through the noise, offering you expert insights, practical advice, and a clear path to selecting a hand truck that not only meets but exceeds your expectations for durability, performance, and safety. We’ll explore everything from essential features to operational best practices, ensuring you make an informed decision.

Heavy Duty Hand Trucks For Sale: Your Ultimate Guide to Moving Mountains Safely and Efficiently

Why Heavy Duty Hand Trucks Are Non-Negotiable for Serious Lifting

In any scenario involving substantial loads, relying on brute strength alone is a recipe for inefficiency, injury, and potential damage to goods. Heavy duty hand trucks are specifically engineered to handle significant weight, providing the mechanical advantage needed to move items safely and easily. They protect both your team and your valuable inventory.

Based on my experience working with countless businesses and individuals, investing in a robust hand truck drastically reduces physical strain. It minimizes the risk of back injuries, which are unfortunately common in manual lifting tasks. Furthermore, these tools significantly speed up the transportation process, leading to increased productivity and smoother operations. They are not just tools; they are investments in safety and efficiency.

Understanding the "Heavy Duty" Factor: What Sets Them Apart?

When we talk about "heavy duty," we’re referring to more than just a marketing term. It signifies a fundamental difference in design, construction, and capacity compared to standard, lighter-duty models. These hand trucks are built to withstand rigorous use, frequent heavy loads, and challenging environments.

The primary distinguishing factor is their weight capacity, which typically ranges from 500 lbs up to 1,200 lbs or more. This substantial capacity is supported by superior materials and robust engineering. Every component, from the frame to the wheels, is reinforced to ensure longevity and reliability under stress.

A Closer Look at Types of Heavy Duty Hand Trucks For Sale

The market offers a diverse range of heavy duty hand trucks, each designed for specific applications and environments. Understanding these variations is crucial for choosing the model that best suits your particular needs. Let’s delve into the most common types you’ll encounter when searching for heavy duty hand trucks for sale.

1. Standard Upright Heavy Duty Hand Trucks

These are the quintessential hand trucks, featuring a tall, upright frame, a sturdy nose plate, and two wheels. They are designed for straightforward vertical lifting and transporting of boxes, crates, and stacked items. Their simplicity is their strength, offering reliable performance for everyday tasks.

Standard models excel in environments where items need to be moved short to medium distances on flat surfaces. They are often the go-to choice for warehouses, delivery drivers, and retail stock rooms. When choosing one, pay close attention to the frame material and wheel type, as these significantly impact performance and durability.

2. Convertible (2-in-1, 3-in-1) Heavy Duty Hand Trucks

Convertible hand trucks are the chameleons of the material handling world, offering incredible versatility. A 2-in-1 model typically transitions from an upright two-wheel hand truck to a four-wheel platform cart. Some advanced 3-in-1 models can also transform into an inclined position for specific tasks.

This adaptability makes them ideal for situations where you need to move a variety of load types or navigate different spaces. For instance, you can use the upright mode for tall stacks and then switch to the platform cart for wider, bulkier items. This versatility often translates to greater efficiency and fewer pieces of equipment needed.

3. Stair Climber Heavy Duty Hand Trucks

Navigating stairs with heavy loads is one of the most challenging material handling tasks. Stair climber hand trucks are specifically engineered with a unique wheel configuration, often featuring a three-wheel assembly on each side that rotates to "walk" up and down steps. This design significantly reduces the effort required and enhances safety.

These specialized hand trucks are invaluable for delivery services, appliance movers, and anyone who frequently transports heavy items between different floor levels without access to ramps or elevators. They are a must-have if your operational environment includes stairs. Look for models with robust frames and ergonomic handles for maximum control.

4. Specialty Heavy Duty Hand Trucks

Beyond the main categories, there are several specialty heavy duty hand trucks designed for very specific purposes.

- Appliance Hand Trucks: These often feature additional straps, non-marring pads, and sometimes even stair-climbing capabilities to safely transport refrigerators, washers, and dryers.

- Drum Hand Trucks: Built with curved frames and often a specialized nose plate or hook, these are designed to secure and move heavy barrels or drums.

- Folding Hand Trucks: While many folding hand trucks are lighter duty, some heavy-duty versions exist, offering portability and compact storage. These are excellent for mobile professionals or those with limited storage space.

Each specialty truck addresses a unique challenge, providing tailored solutions that improve both safety and efficiency for specific types of loads.

Key Features to Look For When Buying Heavy Duty Hand Trucks For Sale

To ensure you invest in a hand truck that truly meets your demands, it’s essential to scrutinize its core features. These elements dictate performance, durability, and user experience.

1. Weight Capacity

This is arguably the most critical feature. Always choose a hand truck with a capacity that comfortably exceeds the heaviest load you anticipate moving. Overloading a hand truck is extremely dangerous and can lead to equipment failure, injury, or damaged goods. A good rule of thumb is to add a 20-30% buffer to your maximum expected load.

2. Frame Material and Construction

The material of the frame directly impacts the hand truck’s strength, weight, and resistance to corrosion.

- Steel: Known for its exceptional strength and durability, steel frames are often heavier but can withstand significant abuse. They are excellent for the heaviest loads and rugged environments.

- Aluminum: Lighter than steel, aluminum hand trucks are easier to maneuver and transport, reducing user fatigue. While still very strong, they might be better suited for applications where weight is a primary concern but extreme loads are less frequent.

- Hybrid Designs: Some models combine steel for critical stress points and aluminum for other sections, offering a balance of strength and reduced weight.

Pro tips from us: Always inspect welds and structural integrity. A well-constructed frame will have smooth, consistent welds and no visible weak points.

3. Wheel Types

The wheels are your hand truck’s direct interface with the ground, and their type significantly affects maneuverability, load stability, and performance on different terrains.

- Pneumatic (Air-Filled) Wheels: Offer excellent shock absorption, making them ideal for rough or uneven surfaces like gravel, grass, or cracked pavement. They provide a smoother ride but require occasional air pressure checks and can be susceptible to punctures.

- Solid Rubber Wheels: Puncture-proof and maintenance-free, solid rubber wheels are durable and perform well on smooth, hard surfaces. They offer less shock absorption than pneumatic wheels, which can make for a bumpier ride on rough terrain.

- Semi-Pneumatic Wheels: A compromise between solid and pneumatic, these wheels have a cushion but don’t require air. They offer some shock absorption without the risk of flats.

- Stair Climber Wheels: As discussed, these specialized wheel assemblies are designed for navigating stairs.

Consider your typical operating environment carefully. The right wheels can make a world of difference in user comfort and operational efficiency.

4. Nose Plate Size and Design

The nose plate, or toe plate, is where the load rests. Its size, shape, and material are crucial for securely handling items.

- Size: A larger nose plate provides more surface area and stability for bulky items. A smaller, narrower plate might be better for compact loads or navigating tight spaces.

- Material: Steel nose plates are common for heavy duty applications due to their strength. Some may feature an angled edge to easily slide under loads.

- Design: Some nose plates are extendable or foldable, offering versatility for different load sizes or compact storage.

Ensure the nose plate can comfortably accommodate the base of your typical loads without allowing them to tip or slide off.

5. Handle Types

The handle is your primary control point, affecting ergonomics and maneuverability.

- P-Handle (Loop Handle): This single, continuous loop handle offers multiple grip positions and allows for one-handed operation, which can be useful when opening doors or stabilizing the load with the other hand.

- Dual Handles: Two separate handles, similar to bicycle handlebars, provide a firm, two-handed grip for maximum control and leverage.

- Straight Back Handles: A simple, straight crossbar handle. Less common on heavy-duty models but still found.

Choose a handle type that feels comfortable and provides optimal control for the types of loads and movements you’ll be performing.

6. Ergonomics and User Comfort

A heavy duty hand truck should not only be strong but also comfortable and safe to use. Features like ergonomic handle grips, balanced design, and smooth-rolling wheels contribute significantly to reducing user fatigue and preventing injuries. Look for designs that minimize the need for excessive bending or awkward postures.

7. Brakes and Accessories

While not standard on all hand trucks, some models, particularly convertible or specialty ones, may offer braking systems for added safety on inclines or when parking a loaded truck. Accessories like cargo straps, bungee cords, or load extenders can also enhance safety and versatility.

Choosing the Right Heavy Duty Hand Truck For Your Needs

With so many excellent heavy duty hand trucks for sale, making the final decision requires a structured approach. Consider these factors carefully to ensure your investment is a smart one.

1. Assess Your Typical Load

What are you primarily moving? Consider the weight, dimensions, and shape of your most common items. This will guide your decisions on weight capacity, nose plate size, and potentially the need for specialty features. Are you moving tall stacks of boxes or wide, bulky appliances?

2. Consider the Terrain and Environment

Where will you be using the hand truck?

- Smooth warehouse floors: Solid rubber or semi-pneumatic wheels are usually sufficient.

- Outdoor, uneven surfaces: Pneumatic wheels are highly recommended for their shock absorption.

- Stairs or ramps: A stair climber hand truck is essential, or a model with good braking if navigating ramps.

- Tight spaces or doorways: Look for models with a compact footprint or maneuverable handles.

3. Evaluate Storage Space and Portability

Do you need to store the hand truck compactly when not in use? A folding or convertible model might be ideal if space is limited or if you need to transport the hand truck in a vehicle. For a fixed warehouse environment, storage might be less of a concern.

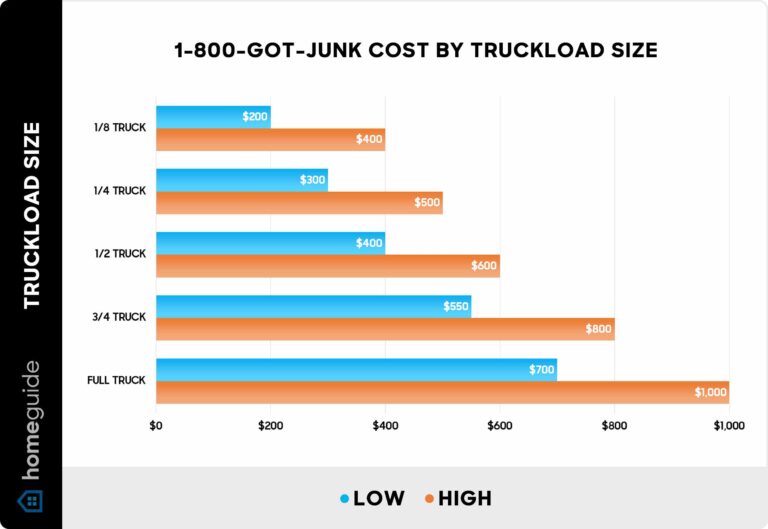

4. Budget Considerations

While quality heavy duty hand trucks for sale represent an investment, there’s a range of price points. Balance your budget with the features and durability you need. Remember, skimping on a heavy duty tool can lead to premature wear, inefficiency, and safety risks. Investing in a durable, high-quality hand truck often pays off in the long run through reduced replacement costs and enhanced operational safety.

Safety First: Operating Your Heavy Duty Hand Truck

Even the most robust hand truck is only as safe as its operator. Proper technique and adherence to safety guidelines are paramount to prevent accidents and injuries.

1. Pre-Use Checks

Before every use, quickly inspect your hand truck.

- Wheels: Check for proper inflation (if pneumatic), damage, or excessive wear. Ensure they spin freely.

- Frame: Look for cracks, bends, or loose fasteners.

- Nose Plate: Ensure it’s securely attached and undamaged.

- Handles: Confirm they are secure and provide a firm grip.

Common mistakes to avoid are skipping these vital checks, which can lead to unexpected failures during operation.

2. Proper Loading Techniques

- Center the Load: Always place the heaviest part of the load as close to the hand truck’s axle as possible. This distributes weight evenly and improves stability.

- Secure the Load: Use straps or bungee cords, especially for tall or unstable items. This prevents shifting or falling, which can cause injury or damage.

- Don’t Overload: Never exceed the hand truck’s stated weight capacity. If a load feels too heavy or unstable, break it down into smaller, manageable portions or get assistance.

3. Correct Posture and Movement

- Push, Don’t Pull (if possible): Pushing allows you to use your body weight and maintain better visibility. Pulling can strain your back.

- Keep Back Straight: Bend at your knees, not your waist, when sliding the nose plate under a load.

- Maintain Good Grip: Use both hands on the handles for maximum control.

- Walk, Don’t Run: Maintain a controlled pace, especially when navigating turns or obstacles.

4. Navigating Obstacles and Terrain

- Clear Your Path: Always ensure your route is free of obstructions, spills, or tripping hazards.

- Doorways and Ramps: Approach slowly and carefully. Use caution on inclines, ensuring the load is stable. If going down a ramp, keep the load on the downhill side of the hand truck for better control.

- Stairs (with a stair climber): Follow the manufacturer’s specific instructions for stair climbing. Ensure the load is securely strapped.

For more detailed safety guidelines on manual material handling, it’s always wise to consult trusted external resources like OSHA’s guidelines on preventing sprains and strains (https://www.osha.gov/manual-material-handling). Safety is a continuous effort, not a one-time check.

Where to Find Quality Heavy Duty Hand Trucks For Sale

Once you’ve narrowed down your ideal hand truck specifications, the next step is finding a reputable supplier.

- Online Retailers: Large e-commerce platforms offer a vast selection from various brands, often with competitive pricing and customer reviews. Be sure to check return policies and shipping costs for large items.

- Specialized Material Handling Suppliers: These companies often carry a wider range of industrial-grade equipment and can offer expert advice. They may also provide better after-sales support and parts.

- Local Industrial Supply Stores: Buying locally allows you to physically inspect the hand truck before purchase and provides immediate access to customer service.

When evaluating a seller, look for good customer reviews, clear warranty information, and responsive customer support. A reliable vendor will stand behind their products.

Investment vs. Cost: Why Quality Matters

It might be tempting to opt for the cheapest option when looking for heavy duty hand trucks for sale. However, this is one area where a slightly higher initial investment can yield significant long-term returns. A cheaply made hand truck can quickly wear out, break down, or, worse, fail under load, leading to injuries, damaged goods, and repeated replacement costs.

A quality heavy duty hand truck, built with durable materials and solid construction, will last for years, even under constant heavy use. It provides consistent, reliable performance, enhances safety, and ultimately contributes to the smooth, efficient operation of your business or project. Consider it an essential tool, not just an expense. If you’re also exploring other equipment for your operations, you might find our guide on Choosing the Right Pallet Jack helpful.

Conclusion: Empower Your Operations with the Right Heavy Duty Hand Truck

Navigating the world of heavy duty hand trucks for sale doesn’t have to be a daunting task. By understanding the different types, scrutinizing key features, and prioritizing safety, you can confidently select a tool that will serve you reliably for years to come. Remember, the goal is not just to move heavy items, but to move them safely, efficiently, and with minimal effort.

A well-chosen heavy duty hand truck is more than just a piece of equipment; it’s a productivity enhancer, a safety device, and a true workhorse. Invest wisely, operate safely, and watch as you effortlessly move those mountains that once seemed insurmountable. For further insights into optimizing your workspace, don’t miss our article on Efficient Warehouse Layouts.